|

Engine Control Module

|

|

Manifold Absolute Pressure/Barometric Pressure Sensor Circuit

Low

|

102

|

4

|

|

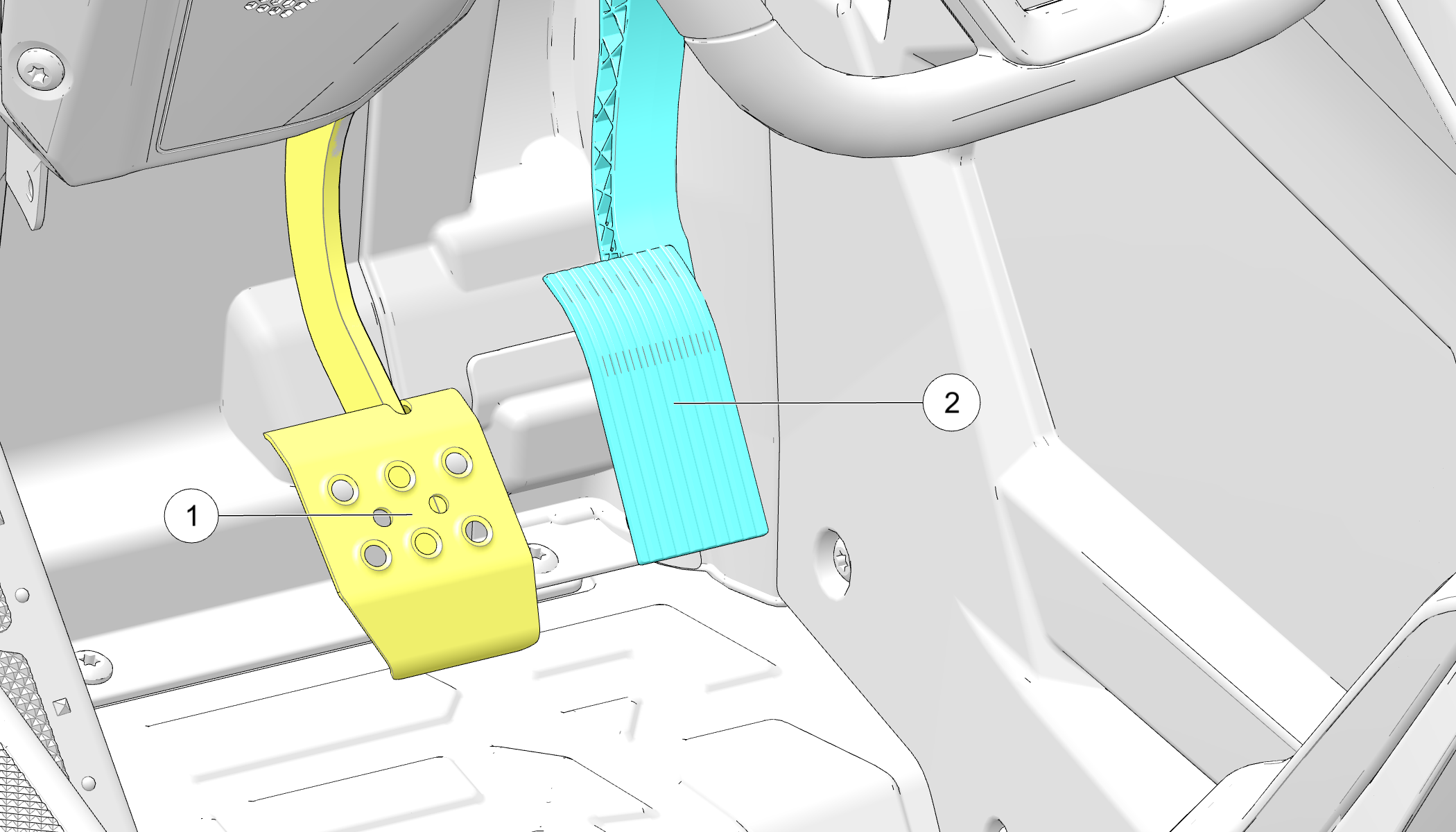

Accelerator Position 2 Voltage Too Low

|

29

|

4

|

|

System Voltage Low

|

168

|

4

|

|

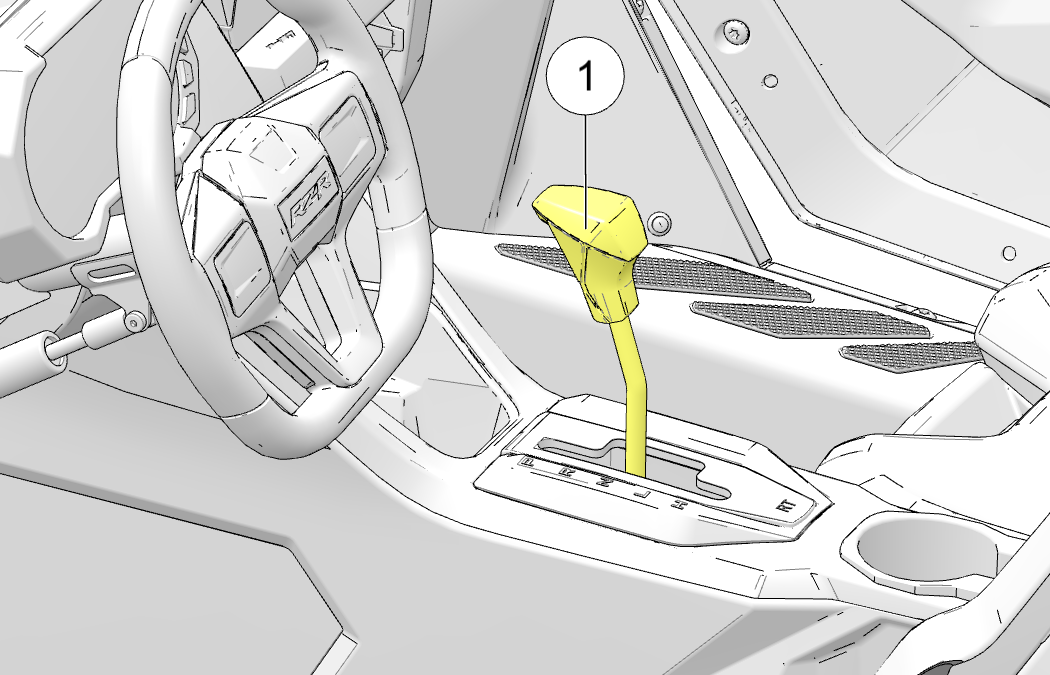

Gear Shift Position Circuit "A" Low

|

523

|

4

|

|

Engine Coolant Temperature Sensor 1 Circuit High

|

110

|

3

|

|

Engine Temperature Sensor Engine Overheat Shutdown

|

110

|

0

|

|

Engine Coolant Temperature Sensor 1 Circuit Low

|

110

|

4

|

|

Crankshaft Position Sensor "A" Circuit

|

636

|

8

|

|

Accelerator Position 2 Voltage Too High

|

29

|

3

|

|

Barometric Pressure Sensor "A" Circuit Low

|

108

|

4

|

|

Engine Coolant Over Temperature Condition

|

110

|

16

|

|

Camshaft Position Sensor "A" Circuit Bank 1 or Single Sensor

|

637

|

8

|

|

Engine Coolant Temperature Sensor 1 Circuit Intermittent/Erratic

|

110

|

10

|

|

Manifold Absolute Pressure/Barometric Pressure Sensor Circuit

High

|

102

|

3

|

|

System Voltage High

|

168

|

3

|

|

Intake Air Temperature Sensor 1 Circuit Intermittent Bank

1

|

105

|

10

|

|

Fuel Level Sensor "A" Circuit Low

|

96

|

4

|

|

Throttle/Pedal Position Sensor/Switch "A" Circuit High

|

51

|

3

|

|

Throttle/Pedal Position Sensor/Switch "C" Circuit Low

|

91

|

4

|

|

Fuel Level Sensor "A" Circuit High

|

96

|

3

|

|

Barometric Pressure Sensor "A" Circuit High

|

108

|

3

|

|

Vehicle Speed Sensor "A" Circuit Intermittent/Erratic/High

|

84

|

2

|

|

Intake Air Temperature Sensor 1 Circuit High Bank 1

|

105

|

3

|

|

Crankshaft Position Sensor "A" Circuit Intermittent

|

636

|

2

|

|

Engine Speed Error in Engine Speed Computation

|

190

|

31

|

|

Intake Air Temperature Sensor 1 Circuit Low Bank 1

|

105

|

4

|

|

Throttle/Pedal Position Sensor/Switch "C" Circuit High

|

91

|

3

|

|

Throttle/Pedal Position Sensor/Switch "A" Circuit Low

|

51

|

4

|

|

Fan Relay Driver Circuit Driver Circuit Short to B+

|

1071

|

3

|

|

Ignition Coil "A" Primary Control Circuit High

|

1268

|

3

|

|

Fuel Pump Primary Circuit

|

1347

|

5

|

|

HO2S Heater Control Circuit High Bank 1 Sensor 1

|

520209

|

3

|

|

Cylinder 1 Injector "A" Circuit High

|

651

|

3

|

|

Low Speed CAN Communication Bus

|

516125

|

2

|

|

Injector 3 Driver Circuit Grounded

|

653

|

4

|

|

Knock/Combustion Vibration Sensor "A" Circuit Range/Performance

|

731

|

2

|

|

Starter Relay "A" Circuit Low

|

677

|

4

|

|

Ignition Coil "B" Primary Control Circuit High

|

1269

|

3

|

|

Cylinder 2 Injector "A" Circuit High

|

652

|

3

|

|

ECU Output Supply Voltage 2 Voltage Above Warning Level

|

3598

|

16

|

|

Cylinder 3 Injector "A" Circuit High

|

653

|

3

|

|

Ignition Coil "B" Primary Control Circuit Low

|

1269

|

4

|

|

Cylinder 4 Injector "A" Circuit High

|

654

|

3

|

|

Fuel Pump Secondary Circuit Low

|

1347

|

4

|

|

Fuel Pump Secondary Circuit High

|

1347

|

3

|

|

Cylinder 1 Injector "A" Circuit Low

|

651

|

4

|

|

Cylinder 2 Injector "A" Circuit

|

652

|

5

|

|

Cylinder 4 Injector "B" Circuit Low

|

654

|

4

|

|

O2 Sensor Circuit Low Voltage Bank 1 Sensor 1

|

3056

|

4

|

|

HO2S Heater Control Circuit Low Bank 1 Sensor 1

|

520209

|

4

|

|

EVAP System Purge Control Valve "A" Circuit

|

520202

|

3

|

|

Chassis Relay Driver Circuit Grounded

|

520208

|

4

|

|

All Wheel Drive Control Circuit Driver Circuit Grounded

|

520207

|

4

|

|

Chassis Relay Driver Circuit Open/Grounded

|

520208

|

5

|

|

HO2S Heater Control Circuit Bank 1 Sensor 1

|

520209

|

5

|

|

Ignition Coil Primary Driver 3 Driver Circuit Grounded

|

1270

|

4

|

|

Throttle/Pedal Position Sensor/Switch "B" Circuit High

|

520198

|

3

|

|

Misfire Detected - Fueling Disabled

|

65590

|

31

|

|

ECU Output Supply Voltage 2 Voltage Below Warning Level

|

3598

|

18

|

|

EVAP System Purge Control Valve "A" Circuit Open

|

520202

|

5

|

|

Cylinder 1 Misfire Detected

|

65591

|

7

|

|

Cylinder 3 Misfire Detected

|

65593

|

7

|

|

O2 Sensor Circuit Bank 1 Sensor 1

|

3056

|

5

|

|

Random/Multiple Cylinder Misfire Detected

|

65599

|

7

|

|

Cylinder 2 Injector "A" Circuit Low

|

652

|

4

|

|

Single Cylinder Misfire (Cylinder not Specified)

|

65590

|

7

|

|

Cylinder 4 Injector "A" Circuit Low

|

654

|

5

|

|

Fan Relay Driver Circuit Driver Circuit Grounded

|

1071

|

4

|

|

Ignition Coil "A" Primary Control Circuit Low

|

1268

|

4

|

|

Powertrain Relay Stuck

|

66013

|

7

|

|

Fan Relay Driver Circuit Driver Circuit Open/Grounded

|

1071

|

5

|

|

Cylinder 1 Injector "A" Circuit

|

651

|

5

|

|

Ignition Coil Primary Driver 3 Driver Circuit Short to B+

|

1270

|

3

|

|

Cylinder 4 Misfire Detected

|

65594

|

7

|

|

O2 Sensor Circuit High Voltage Bank 1 Sensor 1

|

3056

|

3

|

|

ECU Output Supply Voltage 1 Voltage Above Warning Level

|

3597

|

16

|

|

All Wheel Drive Control Circuit Driver Circuit Short to

B+

|

520207

|

3

|

|

Accelerator Sensor Synchronicity Fault - Sensor Difference

Exceeds Limit Condition Exists

|

520308

|

31

|

|

Throttle Body Control - Limp Home Position Check Failed

Condition Exists

|

520280

|

31

|

|

Throttle Position Sensor Neither Position Sensor Passed

Test

|

520276

|

12

|

|

Function Monitoring MoFTrq Comparison Error

|

520385

|

31

|

|

Throttle Body Control - Mechanical Stop Adptation Failure

Condition Exists

|

520281

|

31

|

|

RBA Monitoring Error Memory Read/Write

|

520383

|

31

|

|

ECU ADC Fault - No Load Condition Exists

|

520306

|

31

|

|

EVAP System Purge Control Valve "A" Circuit Shorted

|

520202

|

4

|

|

Chassis Relay Driver Circuit Short to B+

|

520208

|

3

|

|

ETC Accelerator Position Sensor Outputs 1 & 2 Correlation.

Correlation Fault

|

65613

|

2

|

|

Cylinder 3 Injector "A" Circuit Low

|

653

|

5

|

|

All Wheel Drive Control Circuit Driver Circuit Open/Grounded

|

520207

|

5

|

|

ECU Output Supply Voltage 1 Voltage Below Warning Level

|

3597

|

18

|

|

Cylinder 2 Misfire Detected

|

65592

|

7

|

|

Ignition Coil Primary Driver 4 Driver Circuit Short to B+

|

1271

|

3

|

|

Throttle/Pedal Position Sensor/Switch "B" Circuit Low

|

520198

|

4

|

|

EMM Alarm FCCU Hardware Module

|

520248

|

31

|

|

RBA Monitoring Error T15

|

520384

|

31

|

|

Monitoring Error Starter Release

|

520390

|

31

|

|

ECU ADC Fault - Voltage Condition Exists

|

520307

|

31

|

|

ICO Request MoCSOP Module

|

520386

|

31

|

|

ECU Monitoring of Injection Cut Off (Level 2) Condition

Exists

|

520289

|

31

|

|

Throttle Body Control - Power Stage Not Plausible

|

520277

|

2

|

|

Knock Sensor Positive Line Voltage Too High

|

520331

|

3

|

|

Knock Sensor Positive Line Voltage Too Low

|

520331

|

4

|

|

Brake Switch (1 or 2 Indeterminable) Brake Switch Correlation

Fault

|

520285

|

2

|

|

Intake Air System Leak Bank 1

|

520338

|

31

|

|

Drive Mode Select Switch Signal Fault

|

524067

|

2

|

|

Knock Sensor Negative Line Voltage Too High

|

520332

|

3

|

|

Throttle Body Control - Power Stage Minimum

|

520277

|

4

|

|

Monitoring Error Post Build

|

520387

|

31

|

|

ECU Monitoring Error (Level 3) Condition Exists

|

520287

|

31

|

|

Throttle Body Control - Power Stage Signal Error

|

520277

|

8

|

|

High Speed CAN Communication Bus

|

521092

|

2

|

|

Drive Mode Select Switch Voltage Too High

|

524067

|

3

|

|

Accelerator Position/Brake Position Interaction Condition

Exists

|

520275

|

31

|

|

System Too Lean Off Idle Bank 1

|

520344

|

17

|

|

Throttle Body Control - Power Stage Maximum

|

520277

|

3

|

|

Throttle Body Control - Position Deviation Fault Condition

Exists

|

520284

|

31

|

|

ECU Monitoring of Injection Cut Off (Level 1) Condition

Exists

|

520288

|

31

|

|

Knock Sensor Negative Line Voltage Too Low

|

520332

|

4

|

|

Throttle Body Control - Adaption Aborted Condition Exists

|

520279

|

31

|

|

System Too Rich Off Idle Bank 1

|

520344

|

15

|

|

Throttle Body Control Maximum

|

520283

|

3

|

|

Drive Mode Select Switch Voltage Too Low

|

524067

|

4

|

|

Monitoring Error ECU Ignition Check

|

520388

|

31

|

|

Throttle Body Control - Return Spring Check Failed Condition

Exists

|

520278

|

31

|

|

Function Monitoring MoFAir Group

|

520249

|

31

|

|

RBA Monitoring Error Keep Alive

|

520382

|

31

|

|

Throttle Position Sensor Position Sensor Correlation Fault

|

520276

|

2

|

|

Torque Request CAN Message

|

65557

|

22

|

|

Front Wheel Back Drive (Active Descent System) Driver Circuit

Open/Grounded

|

520203

|

5

|

|

Front Wheel Back Drive (Active Descent System) Driver Circuit

Short to B+

|

520203

|

3

|

|

Gear Sensor Signal Abnormal Update Rate

|

523

|

9

|

|

Lost Communication With Front Controls/Display Interface

Module

|

524067

|

9

|

|

Brake Lamp Open Circuit

|

520320

|

5

|

|

Brake Lamp Shorted to Ground

|

520320

|

4

|

|

Front Wheel Back Drive (Active Descent System) Driver Circuit

Grounded

|

520203

|

4

|

|

ESC 65312 checksum failure

|

65557

|

23

|

|

Brake Lamp Shorted to Battery

|

520320

|

3

|

|

System Too Lean Bank 2

|

520205

|

17

|

|

Coolant Thermostat (Coolant Temperature Below Thermostat

Regulating Temperature)

|

110

|

17

|

|

Engine Coolant Temperature Sensor 1 Circuit Intermittent/Erratic

|

110

|

10

|

|

Rear Differential Output Driver Circuit Open/Grounded

|

746

|

5

|

|

System Too Lean Bank 1

|

520204

|

17

|

|

Rear Differential Output Driver Circuit Grounded

|

746

|

4

|

|

Knock/Combustion Vibration Sensor "A" Circuit Range/Performance

|

731

|

2

|

|

Rear Differential Output Driver Circuit Short to B+

|

746

|

3

|

|

System Power Voltage Below Critical Level

|

168

|

1

|

|

Engine Temperature Sensor Temperature above normal range

|

110

|

15

|

|

System Too Rich Bank 2

|

520205

|

15

|

|

System Too Rich Bank 1

|

520204

|

15

|

|

Manifold Absolute Pressure/Barometric Pressure Sensor Circuit

Range/Performance

|

102

|

2

|

|

Manifold absolute pressure sensor out of range low

|

102

|

17

|

|

Manifold absolute pressure sensor out of range high

|

102

|

15

|

|

Charge Air Cooler Cooling Fan Control Circuit Low

|

524280

|

4

|

|

Charge Air Cooler Cooling Fan Control Circuit High

|

524280

|

3

|

|

Gear Shift Position Circuit "A" High

|

523

|

3

|

|

O2 Sensor Signal Biased/Stuck Lean Bank 2 Sensor 1

|

3057

|

17

|

|

Ambient Air Temperature Sensor Circuit "A" High

|

171

|

3

|

|

AC Condenser Fan Relay Open

|

520624

|

5

|

|

Fuel Level Sensor "A" Circuit Range/Performance

|

96

|

2

|

|

O2 Sensor Circuit High Voltage Bank 2 Sensor 1

|

3057

|

3

|

|

AC Condenser Fan Relay Low

|

520624

|

4

|

|

Fuel Level Signal Below Normal Operating Range

|

96

|

18

|

|

O2 Sensor Signal Circuit Shorted to Heater Circuit Bank

1 Sensor 1

|

3056

|

2

|

|

O2 Sensor Signal Biased/Stuck Lean Bank 1 Sensor 1

|

3056

|

17

|

|

O2 Sensor Heater Circuit Bank 1 Sensor 1

|

520209

|

2

|

|

Ambient Air Temperature Sensor Circuit "A" Range/Performance

|

171

|

2

|

|

Crankshaft Position Sensor "A" Circuit Intermittent

|

636

|

2

|

|

O2 Sensor Circuit Low Voltage Bank 2 Sensor 1

|

3057

|

4

|

|

O2 Sensor Circuit Slow Response Bank 1 Sensor 1

|

3056

|

12

|

|

Fuel Level Signal Above Normal Operating Range

|

96

|

16

|

|

System Too Lean Off Idle Bank 2

|

520345

|

17

|

|

Gear Shift Position Circuit "A" Range/Performance

|

523

|

11

|

|

System Too Rich Off Idle Bank 2

|

520345

|

15

|

|

O2 Sensor Signal Biased/Stuck Rich Bank 2 Sensor 1

|

3057

|

15

|

|

O2 Sensor Signal Biased/Stuck Rich Bank 1 Sensor 1

|

3056

|

15

|

|

AC Condenser Fan Relay High

|

520624

|

3

|

|

Charge Air Cooler Cooling Fan Control Circuit/Open

|

524280

|

5

|

|

Ambient Air Temperature Sensor Circuit "A" Low

|

171

|

4

|

|

O2 Sensor Signal Circuit Shorted to Heater Circuit Bank

2 Sensor 1

|

3057

|

2

|

|

O2 Sensor Circuit Slow Response Bank 2 Sensor 1

|

3057

|

12

|

|

Charge Air Cooler Cooling Fan 2 Control Circuit Low

|

524281

|

4

|

|

Charge Air Cooler Cooling Fan 2 Control Circuit High

|

524281

|

3

|

|

Ignition Coil "A" Primary Control Circuit High

|

1268

|

3

|

|

Ignition Coil Primary Driver 3 Driver Circuit Grounded

|

1270

|

4

|

|

Ignition Coil "A" Primary Control Circuit Low

|

1268

|

4

|

|

O2 Sensor Heater Circuit Bank 2 Sensor 1

|

520210

|

2

|

|

Charge Air Cooler Cooling Fan 2 Control Circuit/Open

|

524281

|

5

|

|

Ignition Coil "B" Primary Control Circuit Low

|

1269

|

4

|

|

O2 Sensor Circuit Bank 2 Sensor 1

|

3057

|

5

|

|

Intake Air Temperature Too High

|

105

|

15

|

|

Ignition Coil "B" Primary Control Circuit High

|

1269

|

3

|

|

HO2S Heater Control Circuit High Bank 2 Sensor 1

|

520210

|

3

|

|

HO2S Heater Control Circuit Bank 2 Sensor 1

|

520210

|

5

|

|

HO2S Heater Control Circuit Low Bank 2 Sensor 1

|

520210

|

4

|

|

Ignition Coil Primary Driver 3 Driver Circuit Short to B+

|

1270

|

3

|

|

Ignition Coil Primary Driver 4 Driver Circuit Short to B+

|

1271

|

3

|

|

Knock Sensor 2 Negative Line Short To GND

|

520126

|

4

|

|

Fan 2 Control Circuit Low

|

1557

|

4

|

|

Fan 2 Control Circuit High

|

1557

|

3

|

|

Knock Sensor 2 Negative Line Short To BAT

|

520126

|

3

|

|

Fan 2 Control Circuit

|

1557

|

5

|

|

Knock Sensor 2 Positive Line Short To BAT

|

520127

|

3

|

|

Transmission Mode Switch "A" Circuit

|

520467

|

31

|

|

Knock Sensor 2 Positive Line Short To GND

|

520127

|

4

|

|

System Too Rich at Idle Bank 1

|

520342

|

15

|

|

ECU Output Supply Voltage 2 Voltage Above Critical Level

|

3598

|

0

|

|

Starter Relay "A" Circuit

|

677

|

5

|

|

Throttle Body Control - Return Spring Check Failed Condition

Exists

|

520278

|

31

|

|

System Too Lean at Idle Bank 2

|

520343

|

17

|

|

Transmission Mode Switch "B" Circuit

|

520468

|

31

|

|

ECU Output Supply Voltage 1 Voltage Too Low

|

3597

|

4

|

|

System Too Rich at Idle Bank 2

|

520343

|

15

|

|

Turbocharger/Supercharger Boost Sensor "A" Circuit Low

|

1127

|

4

|

|

Trunk brake lamp short to GND

|

520172

|

4

|

|

Gear Shift Position Circuit "A"

|

523

|

2

|

|

ECU Output Supply Voltage 2 Voltage Too Low

|

3598

|

4

|

|

ECU Memory EEPROM Read/Write Failure

|

628

|

12

|

|

Trunk brake lamp short to BAT

|

520172

|

3

|

|

Turbocharger/Supercharger Boost Sensor "A" Circuit High

|

1127

|

3

|

|

Reverse Override Switch Stuck

|

524145

|

31

|

|

System Too Lean at Idle Bank 1

|

520342

|

17

|

|

ECU Output Supply Voltage 1 Voltage Above Critical Level

|

3597

|

0

|

|

Throttle Body Control - Repeated Adaptation Failed Condition

Exists

|

520282

|

31

|

|

Starter Relay "A" Circuit High

|

677

|

3

|

|

EPS Module

|

|

Software initialization error

|

520229

|

31

|

|

ECU Memory EEPROM Read/Write Failure

|

628

|

12

|

|

Steering motor current uncontrolled

|

520222

|

6

|

|

Excessive EPS internal temperature

|

520225

|

0

|

|

System Power Voltage Too High

|

168

|

3

|

|

Steering angle sensor out of range

|

1807

|

31

|

|

EPS internal temperature warning

|

520225

|

16

|

|

External fault, engine speed reception

|

524000

|

19

|

|

Steering angle sensor not calibrated

|

1807

|

13

|

|

System Power Voltage Too Low

|

168

|

4

|

|

EPAS Power Save Condition Power Save Timeout

|

520231

|

31

|

|

Motor driver IC error

|

520448

|

12

|

|

External fault, vehicle speed reception

|

84

|

19

|

|

Steering Over Current Shut Down Current Above Normal or

Grounded

|

520221

|

6

|

|

Position Encoder Error Position Encoder Error

|

520228

|

11

|

|

Internal fault, thermistor malfunction

|

520225

|

12

|

|

Motor relay error

|

520552

|

12

|

|

CPU error

|

65580

|

12

|

|

Steering angle sensor out of range

|

1807

|

12

|

|

EPS motor drive voltage out of range

|

520672

|

31

|

|

Power relay error

|

520672

|

12

|

|

Power supply IC error

|

524086

|

12

|

|

Steering Torque Full Failure

|

520224

|

12

|

|

EPAS CAN Communications Transmit Error No TX Message for

x Seconds

|

520227

|

2

|

|

EPS Calibration CRC error

|

630

|

23

|

|

Steering Torque Partial Failure

|

520223

|

12

|

|

Lost Communication With ECM/PCM "A"

|

520226

|

2

|

|

Suspension Control Module

|

|

Suspension Control Module Acceleration Sensor Measurement

Out of Range

|

516115

|

12

|

|

Engine Speed Data Invalid

|

524000

|

2

|

|

Absolute Shock Current Error - Rebound Rear Right

|

516314

|

11

|

|

Steering Angle and Velocity Signal Not Received from Power

Steering Module

|

516117

|

9

|

|

Shock Valve Supply Relay Driver Shorted to Low Source or

Open Circuit

|

516110

|

4

|

|

Suspension Mode Switch Input Voltage in Invalid Range

|

516098

|

2

|

|

Gear Position Signal Not Received from Engine Control Module

|

516121

|

9

|

|

Valve Driver Shorted Low or Open Circuit - Compression Front

Left

|

516106

|

4

|

|

System Voltage below minimum - most severe level

|

516126

|

1

|

|

Absolute Shock Current Error - Compression Rear Right

|

516114

|

11

|

|

Valve Driver Shorted High - Compression Front Right

|

516107

|

3

|

|

Suspension Control Module CAN Communication Transmit Error

|

516125

|

11

|

|

Absolute Shock Current Error - Rebound Rear Left

|

516313

|

11

|

|

Absolute Shock Current Error - Compression Front Right

|

516112

|

11

|

|

Suspension Control Module Temperature Below Normal

|

516115

|

17

|

|

Suspension Mode Switch Input - Voltage below minimum threshold

|

516098

|

4

|

|

Requested Power Steering Mode does not Match Active Power

Steering Mode

|

524116

|

31

|

|

Valve Driver Shorted Low or Open Circuit - Compression Front

Right

|

516107

|

4

|

|

Valve Driver Shorted Low or Open Circuit - Rebound Front

Right

|

523991

|

4

|

|

Absolute Shock Current Error - Compression Rear Left

|

516113

|

11

|

|

Suspension Control Module Temperature Above Normal

|

516115

|

15

|

|

Vehicle Speed Data Implausible Based On Slew Rate

|

516123

|

21

|

|

Vehicle Speed Signal Not Received from Engine Control Module

|

516120

|

9

|

|

Valve Driver Shorted High - Compression Rear Left

|

516108

|

3

|

|

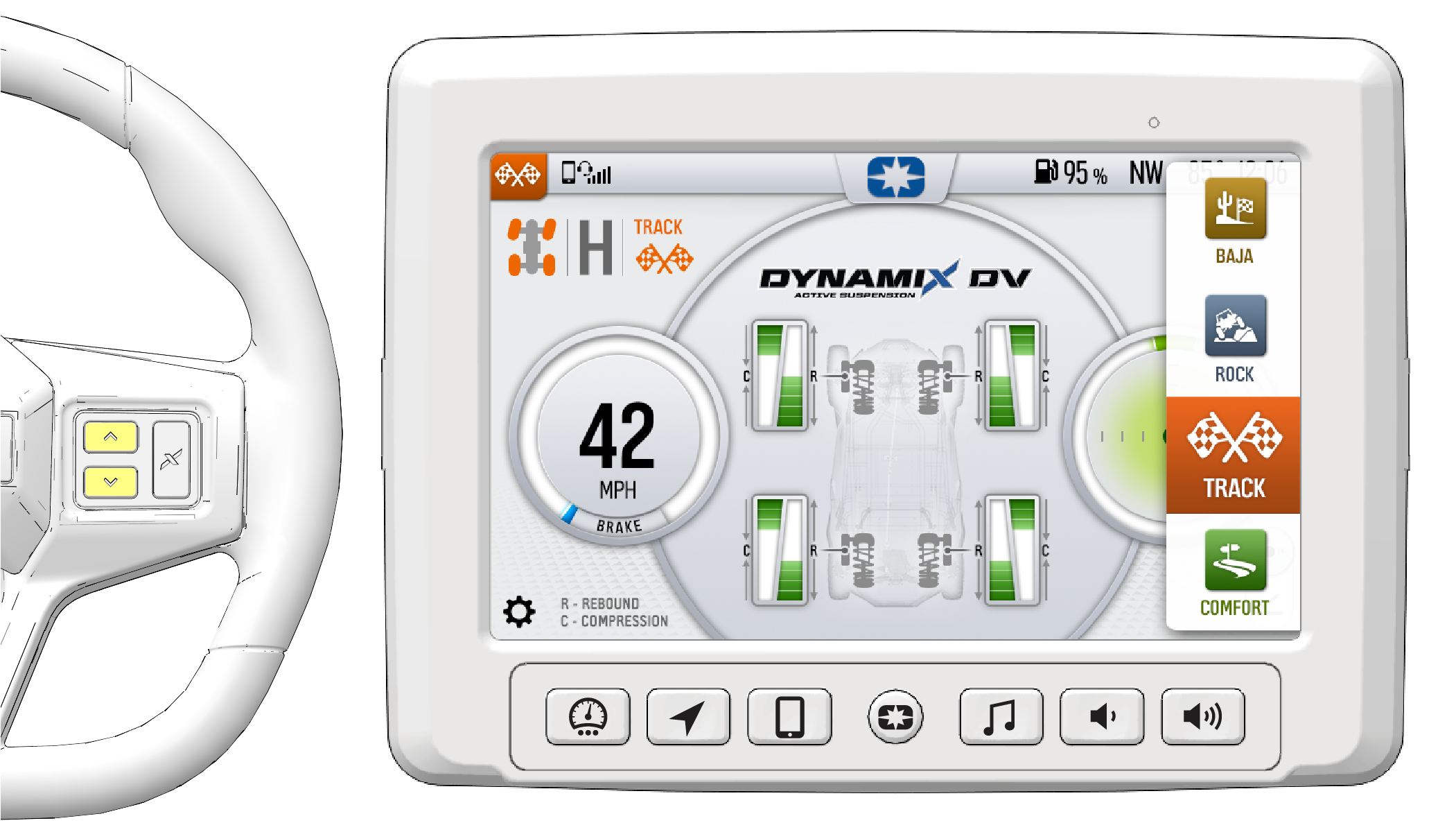

Operator Button 51 [Mode Up] - Data Erratic, Intermittent

Or Incorrect

|

523963

|

2

|

|

Valve Driver Shorted Low or Open Circuit - Compression Rear

Left

|

516108

|

4

|

|

Brake Switch Status Data Invalid

|

520572

|

2

|

|

Vehicle Speed Data - Implausible - Based on Engine Speed

and Gear

|

516123

|

20

|

|

Steering Alignment Out of Range - Above Normal

|

516122

|

15

|

|

Suspension Control Module Mounting Orientation Error Detected

|

516115

|

2

|

|

System Voltage above maximum - most severe level

|

516126

|

0

|

|

Valve Driver Shorted Low or Open Circuit - Compression Rear

Right

|

516109

|

4

|

|

Valve Driver Shorted High - Compression Rear Right

|

516109

|

3

|

|

Valve Driver Shorted High - Compression Front Left

|

516106

|

3

|

|

Mode Up/Down and Pucker Button Signal Not Received from

Steering Wheel

|

516183

|

9

|

|

Operator Button 50 [Pucker] - Data Erratic, Intermittent

Or Incorrect

|

523962

|

2

|

|

Valve Driver Shorted Low or Open Circuit - Rebound Rear

Right

|

523993

|

4

|

|

System Voltage below minimum moderately severe level

|

516126

|

18

|

|

Valve Driver Shorted High - Rebound Front Right

|

523991

|

3

|

|

Valve Driver Shorted High - Rebound Rear Right

|

523993

|

3

|

|

Engine Speed Signal Not Received from Engine Control Module

|

516116

|

9

|

|

Valve Driver Shorted High - Rebound Rear Left

|

523992

|

3

|

|

Operator Button 52 [Mode Down] - Data Erratic, Intermittent

Or Incorrect

|

523964

|

2

|

|

System Voltage above maximum - moderately severe level

|

516126

|

16

|

|

Absolute Shock Current Error - Rebound Front Left

|

516311

|

11

|

|

Absolute Shock Current Error - Rebound Front Right

|

516312

|

11

|

|

Engine Torque Demanded Signal Not Received from Engine Control

Module

|

521038

|

9

|

|

Steering Angle Data Invalid

|

524114

|

2

|

|

Vehicle Speed Data Invalid

|

516123

|

2

|

|

Transmission Requested Range Data Invalid

|

162

|

2

|

|

System Voltage Shorted to High Source

|

516126

|

3

|

|

System Voltage Shorted to Low Source or Open Circuit

|

516126

|

4

|

|

Shock Valve Supply Relay Driver Shorted High

|

516110

|

3

|

|

Valve Driver Shorted Low or Open Circuit - Rebound Front

Left

|

523990

|

4

|

|

Steering Alignment Out of Range - Below Normal

|

516122

|

17

|

|

SW Version / HW Version Compatibility - Data Inconsistent

|

516119

|

2

|

|

Suspension Mode Switch Input - Voltage Above Maximum Threshold

|

516098

|

3

|

|

Absolute Shock Current Error - Compression Front Left

|

516111

|

11

|

|

Accelerator Pedal Position Data Invalid

|

520574

|

2

|

|

Valve Driver Shorted High - Rebound Front Left

|

523990

|

3

|

|

Suspension Control Module Internal Error

|

516124

|

12

|

|

Valve Driver Shorted Low or Open Circuit - Rebound Rear

Left

|

523992

|

4

|

|

Accelerator Pedal Position and Brake Switch Signal Not Received

from Engine Control Module

|

516118

|

9

|

|

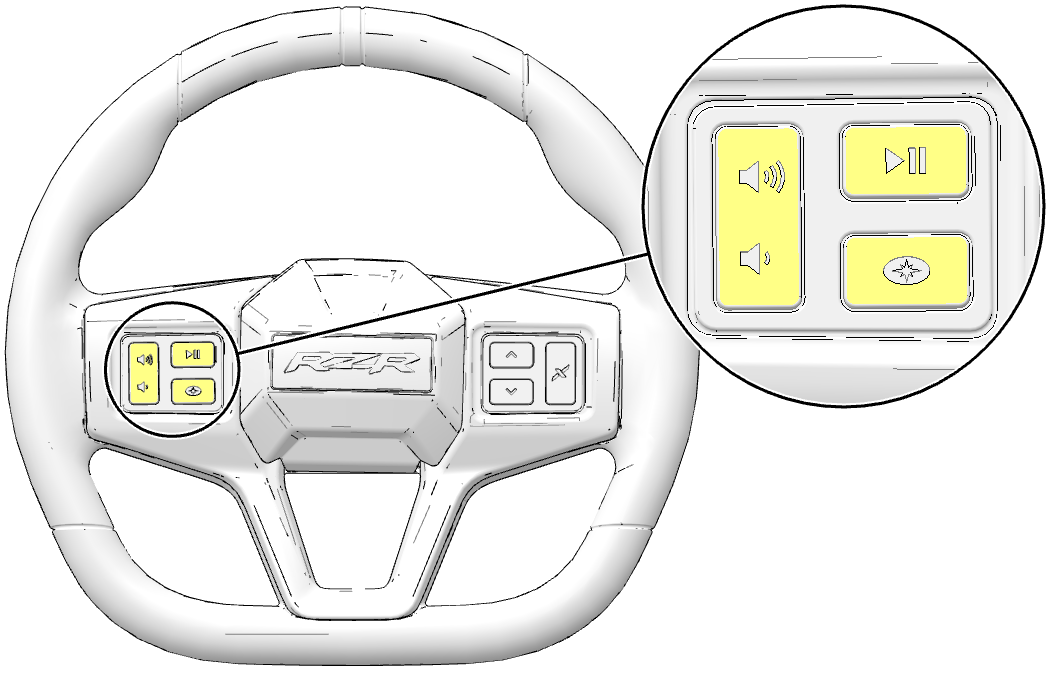

Steering Wheel Controls

|

|

Left Hand Control Watchdog Reset Root Cause Not Known

|

520191

|

11

|

|

Right Hand Control Watchdog Reset Root Cause Not Known

|

520191

|

11

|

|

Instrument Cluster

|

|

Lost Communication With Power Steering Control Module "A"

|

520230

|

31

|

|

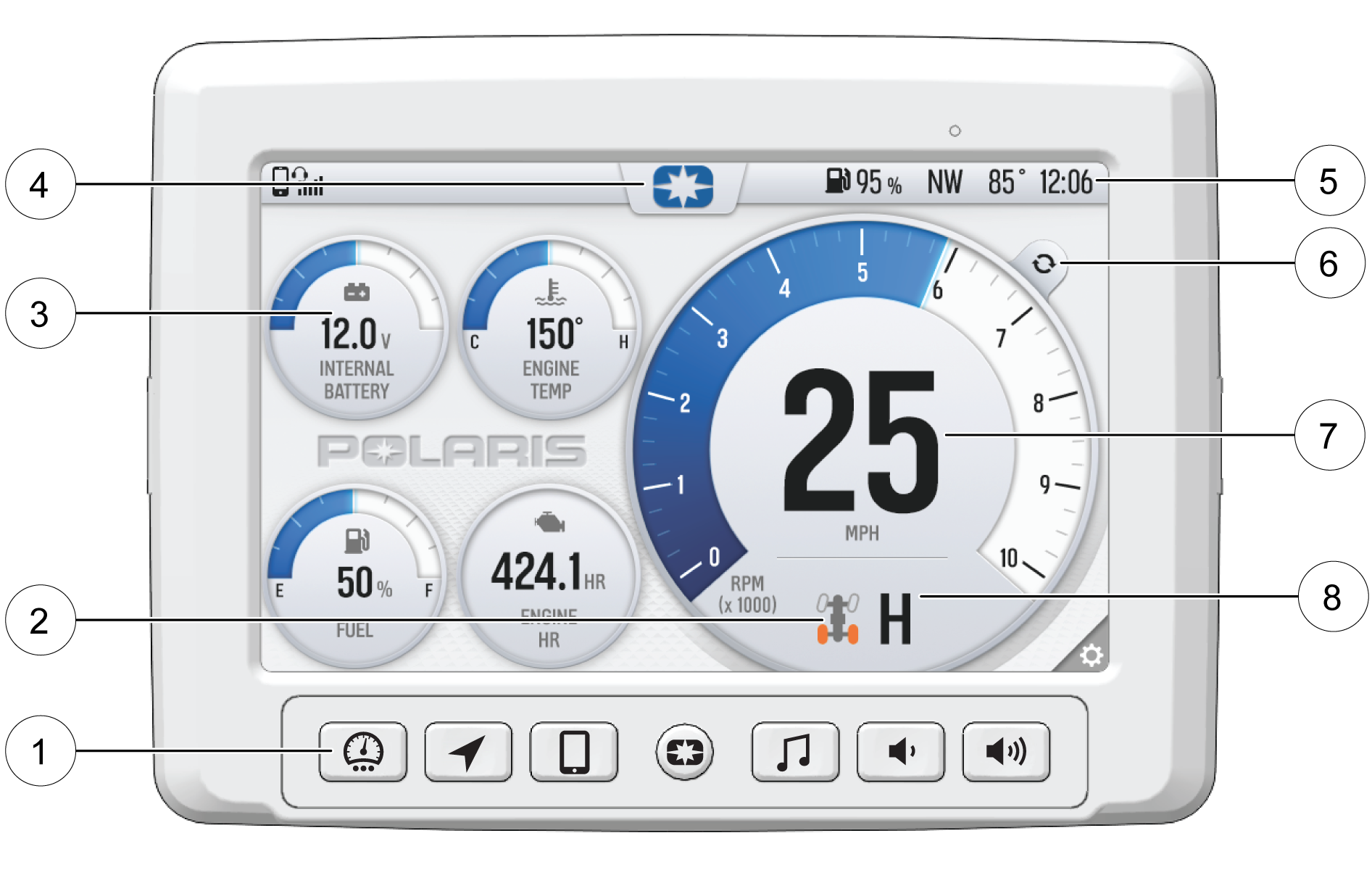

Ride Command Display

|

|

Battery Potential / Power Input 1

|

168

|

1

|