|

Engine Control Module

|

|

Accelerator Position 2

|

Data Erratic, Intermittent Or Incorrect

|

29

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

29

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

29

|

4

|

|

Throttle Position Sensor 1

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

51

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

51

|

1

|

|

Data Erratic, Intermittent Or Incorrect

|

51

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

51

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

51

|

4

|

|

Abnormal Rate Of Change

|

51

|

10

|

|

Out Of Calibration

|

51

|

13

|

|

Vehicle Speed Sensor

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

84

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

84

|

1

|

|

Data Erratic, Intermittent Or Incorrect

|

84

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

84

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

84

|

4

|

|

Abnormal Frequency Or Pulse Width Or Period

|

84

|

8

|

|

Abnormal Update Rate

|

84

|

9

|

|

Abnormal Rate Of Change

|

84

|

10

|

|

Bad Intelligent Device Or Component

|

84

|

12

|

|

Received Network Data In Error

|

84

|

19

|

|

Accelerator Position 1

|

Data Erratic, Intermittent Or Incorrect

|

91

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

91

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

91

|

4

|

|

Manifold Absolute Pressure Sensor

|

Data Erratic, Intermittent Or Incorrect

|

102

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

102

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

102

|

4

|

|

Mechanical System Not Responding Or Out Of Adjustment

|

102

|

7

|

|

Abnormal Rate Of Change

|

102

|

10

|

|

Intake Air Temperature Sensor

|

Data Erratic, Intermittent Or Incorrect

|

105

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

105

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

105

|

4

|

|

Abnormal Rate Of Change

|

105

|

10

|

|

Data Valid But Above Normal Operating Range - Least Severe

Level

|

105

|

15

|

|

Engine Temperature Sensor

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

110

|

0

|

|

Data Erratic, Intermittent Or Incorrect

|

110

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

110

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

110

|

4

|

|

Abnormal Rate Of Change

|

110

|

10

|

|

Data Valid But Above Normal Operating Range - Least Severe

Level

|

110

|

15

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

110

|

16

|

|

Data Valid But Below Normal Operating Range - Least Severe

Level

|

110

|

17

|

|

System Power

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

168

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

168

|

1

|

|

Voltage Above Normal, Or Shorted To High Source

|

168

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

168

|

4

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

168

|

16

|

|

Data Valid But Below Normal Operating Range - Moderately

Severe Level

|

168

|

18

|

|

Engine Speed

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

190

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

190

|

1

|

|

Data Erratic, Intermittent Or Incorrect

|

190

|

2

|

|

Mechanical System Not Responding Or Out Of Adjustment

|

190

|

7

|

|

Received Network Data In Error

|

190

|

19

|

|

Condition Exists

|

190

|

31

|

|

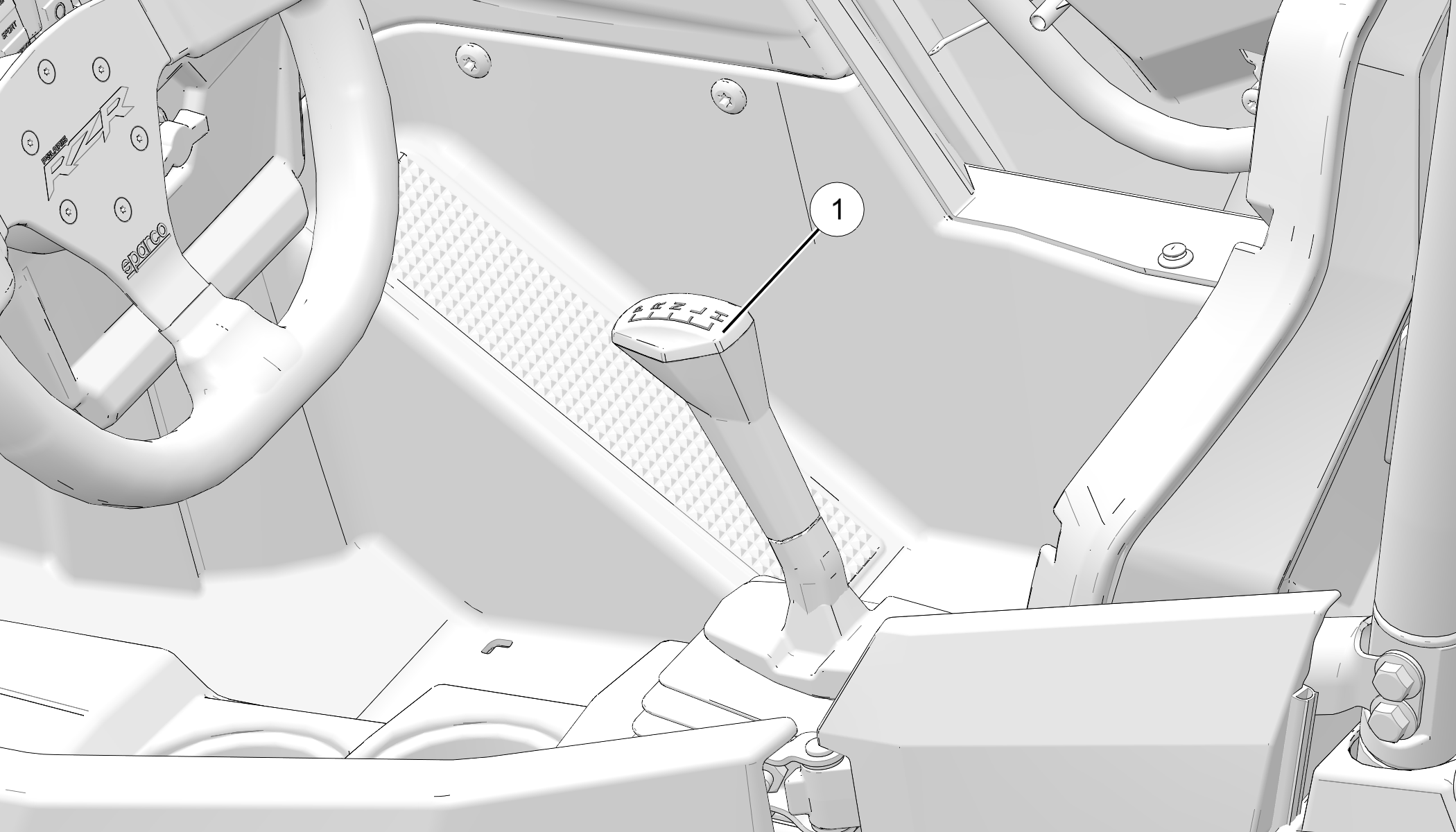

Gear Sensor Signal

|

Data Erratic, Intermittent Or Incorrect

|

523

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

523

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

523

|

4

|

|

Abnormal Update Rate

|

523

|

9

|

|

ECU Memory

|

Bad Intelligent Device Or Component

|

628

|

12

|

|

Out Of Calibration

|

628

|

13

|

|

Calibration

|

Out Of Calibration

|

630

|

13

|

|

Crankshaft Position Sensor

|

Data Erratic, Intermittent Or Incorrect

|

636

|

2

|

|

Abnormal Frequency Or Pulse Width Or Period

|

636

|

8

|

|

Injector 1 (Front) (MAG) (SDI Port

Injector)

|

Voltage Above Normal, Or Shorted To High Source

|

651

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

651

|

4

|

|

Current Below Normal Or Open Circuit

|

651

|

5

|

|

Fan Relay Driver Circuit

|

Voltage Above Normal, Or Shorted To High Source

|

1071

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

1071

|

4

|

|

Current Below Normal Or Open Circuit

|

1071

|

5

|

|

Ignition Coil Primary Driver 1 (Front) (MAG)

|

Voltage Above Normal, Or Shorted To High Source

|

1268

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

1268

|

4

|

|

Current Below Normal Or Open Circuit

|

1268

|

5

|

|

Fuel Pump Driver Circuit

|

Voltage Above Normal, Or Shorted To High Source

|

1347

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

1347

|

4

|

|

Current Below Normal Or Open Circuit

|

1347

|

5

|

|

Oxygen Sensor 1

|

Data Erratic, Intermittent Or Incorrect

|

3056

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

3056

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

3056

|

4

|

|

Bad Intelligent Device Or Component

|

3056

|

12

|

|

ECU Output Supply Voltage 1

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

3597

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

3597

|

1

|

|

Voltage Above Normal, Or Shorted To High Source

|

3597

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

3597

|

4

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

3597

|

16

|

|

Data Valid But Below Normal Operating Range - Moderately

Severe Level

|

3597

|

18

|

|

ECU Output Supply Voltage 2

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

3598

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

3598

|

1

|

|

Voltage Above Normal, Or Shorted To High Source

|

3598

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

3598

|

4

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

3598

|

16

|

|

Data Valid But Below Normal Operating Range - Moderately

Severe Level

|

3598

|

18

|

|

ECU Output Supply Voltage 3

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

3599

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

3599

|

1

|

|

Voltage Above Normal, Or Shorted To High Source

|

3599

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

3599

|

4

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

3599

|

16

|

|

Data Valid But Below Normal Operating Range - Moderately

Severe Level

|

3599

|

18

|

|

ETC Accelerator Position Sensor Outputs 1 & 2 Correlation

|

Data Erratic, Intermittent Or Incorrect

|

65613

|

2

|

|

Throttle Position Sensor 2

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

520198

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

520198

|

1

|

|

Data Erratic, Intermittent Or Incorrect

|

520198

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

520198

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

520198

|

4

|

|

Abnormal Rate Of Change

|

520198

|

10

|

|

Out Of Calibration

|

520198

|

13

|

|

Fuel Correction Front

|

Data Valid But Above Normal Operating Range - Least Severe

Level

|

520204

|

15

|

|

Data Valid But Below Normal Operating Range - Least Severe

Level

|

520204

|

17

|

|

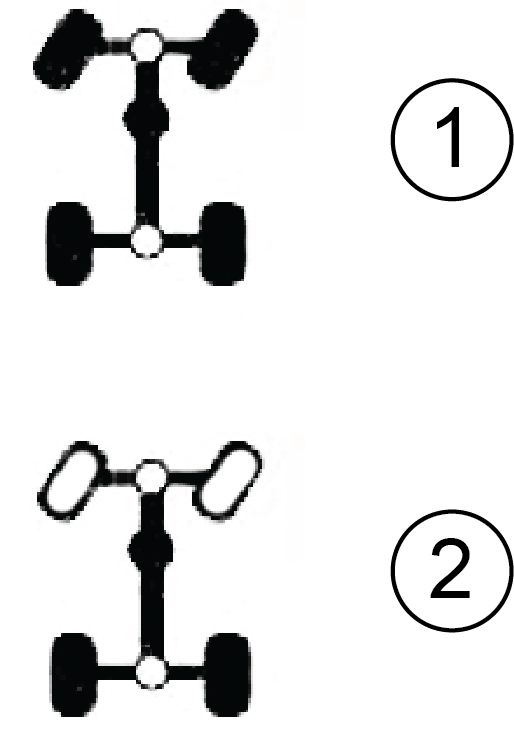

All Wheel Drive Control Circuit

|

Voltage Above Normal, Or Shorted To High Source

|

520207

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

520207

|

4

|

|

Current Below Normal Or Open Circuit

|

520207

|

5

|

|

Oxygen Sensor Heater 1

|

Data Erratic, Intermittent Or Incorrect

|

520209

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

520209

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

520209

|

4

|

|

Current Below Normal Or Open Circuit

|

520209

|

5

|

|

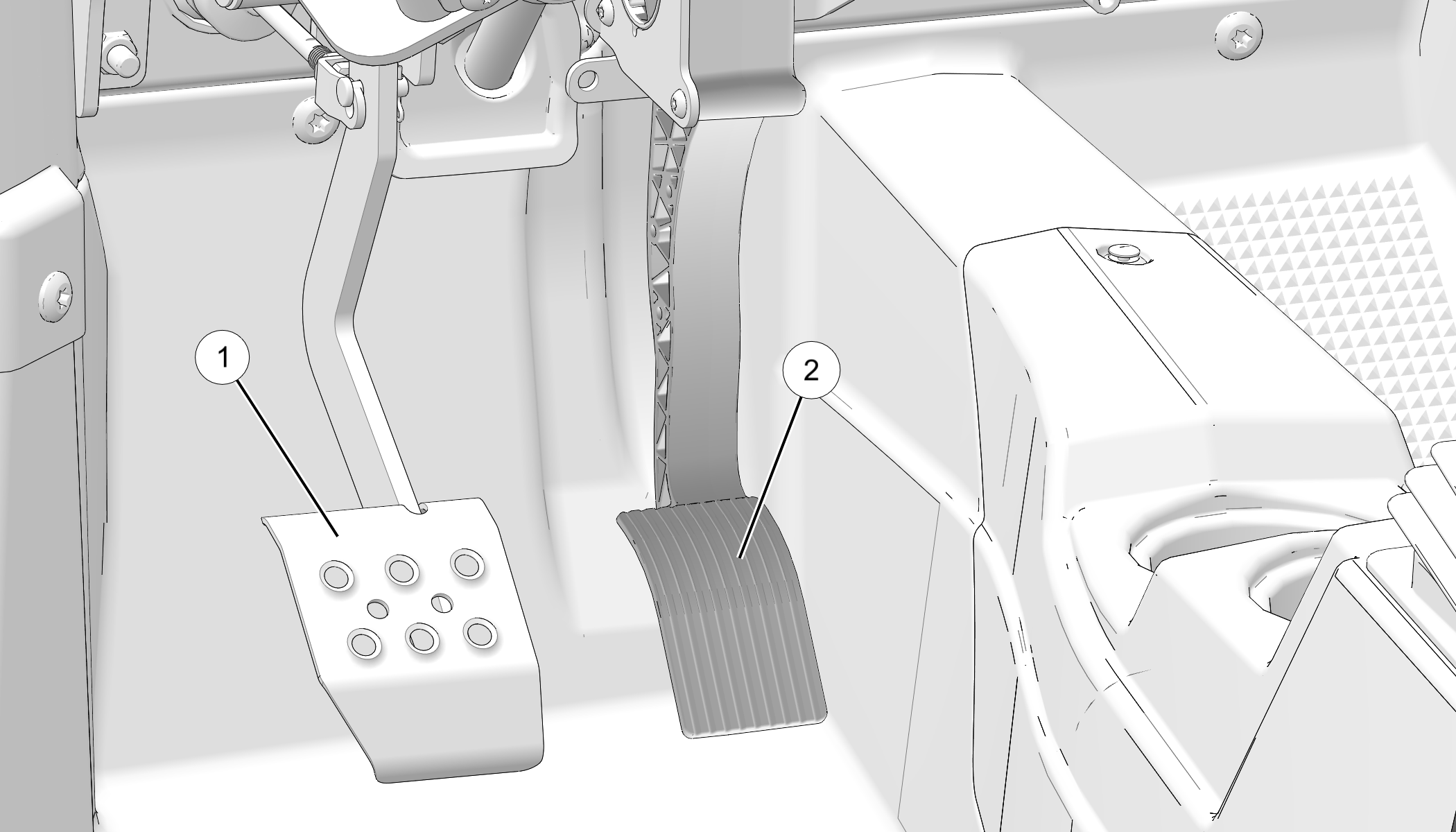

Accelerator Position/Brake Position Interaction

|

Condition Exists

|

520275

|

31

|

|

Throttle Position Sensor (1 or 2 Indeterminable)

|

Data Erratic, Intermittent Or Incorrect

|

520276

|

2

|

|

Bad Intelligent Device Or Component

|

520276

|

12

|

|

Throttle Body Control - Power Stage

|

Data Erratic, Intermittent Or Incorrect

|

520277

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

520277

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

520277

|

4

|

|

Abnormal Frequency Or Pulse Width Or Period

|

520277

|

8

|

|

Condition Exists

|

520277

|

31

|

|

Throttle Body Control - Return Spring Check Failed

|

Condition Exists

|

520278

|

31

|

|

Throttle Body Control - Adaption Aborted

|

Condition Exists

|

520279

|

31

|

|

Throttle Body Control - Limp Home Position Check Failed

|

Condition Exists

|

520280

|

31

|

|

Throttle Body Control - Mechanical Stop Adaptation Failure

|

Condition Exists

|

520281

|

31

|

|

Throttle Body Control - Repeated Adaptation Failed

|

Condition Exists

|

520282

|

31

|

|

Throttle Body Control

|

Data Erratic, Intermittent Or Incorrect

|

520283

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

520283

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

520283

|

4

|

|

Throttle Body Control - Position Deviation Fault

|

Condition Exists

|

520284

|

31

|

|

ECU Monitoring Error

|

Condition Exists

|

520286

|

31

|

|

ECU Monitoring Error (Level 3)

|

Condition Exists

|

520287

|

31

|

|

ECU Monitoring of Injection Cut Off (Level 1)

|

Condition Exists

|

520288

|

31

|

|

ECU Monitoring of Injection Cut Off (Level 2)

|

Condition Exists

|

520289

|

31

|

|

Throttle Body Control - Requested Throttle Angle Not Plausible

|

Condition Exists

|

520305

|

31

|

|

ECU ADC Fault - No Load

|

Condition Exists

|

520306

|

31

|

|

ECU ADC Fault - Voltage

|

Condition Exists

|

520307

|

31

|

|

Accelerator Sensor Sync Fault - Sensor Diff Exceeds Limit

|

Condition Exists

|

520308

|

31

|

|

ECU Fault - ICO

|

Condition Exists

|

520309

|

31

|

|

ECU Fault - Hardware Disruption

|

Condition Exists

|

520311

|

31

|

|

Idle Fuel Correction Bank 1

|

Data Valid But Above Normal Operating Range - Least Severe

|

520342

|

15

|

|

Data Valid But Below Normal Operating Range - Least Severe

|

520342

|

17

|

|

Adaptive Fuel Correction Bank 1

|

Data Valid But Above Normal Operating Range - Least Severe

|

520344

|

15

|

|

Data Valid But Below Normal Operating Range - Least Severe

|

520344

|

17

|

|

EPAS Module

|

|

Steering Over Current Shut Down

|

Current Above Normal Or Grounded Circuit

|

520221

|

6

|

|

Steering Excessive Current Error

|

Current Above Normal Or Grounded Circuit

|

520222

|

6

|

|

Steering Torque Partial Failure

|

Condition Exists

|

520223

|

31

|

|

Steering Torque Full Failure

|

Condition Exists

|

520224

|

31

|

|

EPAS Inverter Temperature

|

Data Valid But Above Normal Operational Range - Most Severe

|

520225

|

0

|

|

Data Valid But Above Normal Operating Range - Severe

|

16

|

|

EPAS

Communications Receive Data Error

|

Data Erratic, Intermittent Or Incorrect

|

520226

|

2

|

|

Condition Exists

|

520226

|

31

|

|

Position Encoder Error

|

Root Cause Not Known

|

520228

|

11

|

|

Bad Intelligent Device Or Component

|

520228

|

12

|

|

Condition Exists

|

520228

|

31

|

|

EPAS Software Error

|

Bad Intelligent Device Or Component

|

520229

|

12

|

|

Condition Exists

|

520229

|

31

|

|

EPAS Power Save Condition

|

Condition Exists

|

520231

|

31

|

|

EPS SEPIC Voltage Error

|

Voltage Above Normal, Or Shorted To High Source

|

524086

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

524086

|

4

|

|

Calibration CRC

|

Checksum/CRC Error

|

630

|

13

|

|

Steering Torque Full Failure

|

Torque Sensor Out of Range

|

520223

|

31

|

|

Torque Sensor Linearity Error

|

520224

|

31

|

|

EPS CAN Communications Receive Error

|

No RX Message for {{cal parameter}} seconds

|

520226

|

2

|

|

Vehicle Speed

|

Vehicle Speed Too High

|

84

|

0

|

|

Vehicle Speed Implausible

|

10

|

|

Received Vehicle Speed has Errors

|

19

|

|

Engine Speed

|

Engine Speed Too High

|

190

|

0

|

|

Received Engine Speed has Errors

|

190

|

19

|

|

Battery Voltage

|

Too High

|

168

|

3

|

|

Battery Voltage

|

Too Low

|

168

|

4

|

|

Position Encoder Error

|

Loss of SPI Communication

|

520228

|

12

|

|

Encoder Variance Error

|

31

|

|

EPS Software Error

|

Manufacturing CRC Error

|

520229

|

12

|

|

Boot Count Error

|

31

|

|

ICS Communication

|

Loss of CAN between EPS and Instrument Cluster

|

520230

|

31

|

|

EPAS Power Save

|

5 minute time out

|

520231

|

31

|

|

ECU Memory

|

EEPROM Communication Error

|

628

|

12

|

|

Application CRC Error

|

13

|

|

VGD Low

|

VGD Low

|

524086

|

4

|

|

Absolute Position Sensor

|

Absolute Position Sensor Out of Range

|

1807

|

31

|

|

Absolute Position Sensor Not Calibrated

|

1807

|

13

|

|

Suspension Control

Module

|

|

Vehicle Speed Sensor

|

Data Drifted High

|

84

|

20

|

|

Data Drifted Low

|

21

|

|

Transmission Requested Range Data

|

Data Erratic, Intermittent Or Incorrect

|

162

|

2

|

|

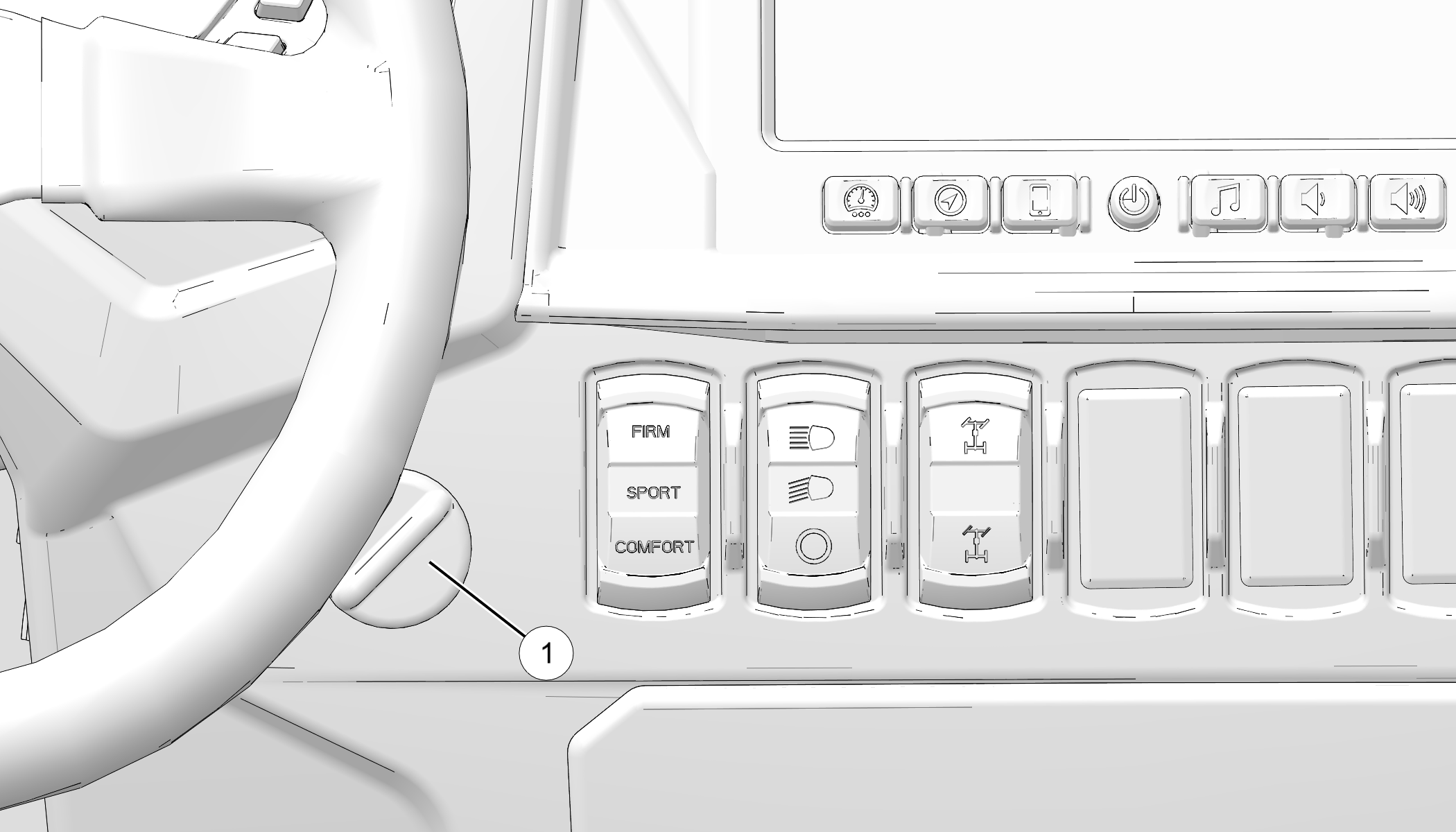

Suspension Mode Switch Input (Turbo S only)

|

Data Erratic, Intermittent Or Incorrect

|

516098

|

2

|

|

Voltage Above Normal, Or Shorted To High Source

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Valve Driver Front Left (Turbo S only)

|

Voltage Above Normal, Or Shorted To High Source

|

516106

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Valve Driver Front Right (Turbo S only)

|

Voltage Above Normal, Or Shorted To High Source

|

516107

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Valve Driver Rear Left (Turbo S only)

|

Voltage Above Normal, Or Shorted To High Source

|

516108

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Valve Driver Rear Right (Turbo S only)

|

Voltage Above Normal, Or Shorted To High Source

|

516109

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Shock Valve Power Supply Relay Driver (Turbo

S only)

|

Voltage Above Normal, Or Shorted To High Source

|

516110

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Absolute Shock Current Error - Front Left (Turbo S only)

|

Root Cause Not Known

|

516111

|

11

|

|

Absolute Shock Current Error - Front Right (Turbo S only)

|

Root Cause Not Known

|

516112

|

11

|

|

Absolute Shock Current Error - Rear Left (Turbo S only)

|

Root Cause Not Known

|

516113

|

11

|

|

Absolute Shock Current Error - Rear Right (Turbo S only)

|

Root Cause Not Known

|

516114

|

11

|

|

Internal Inertial Measurement Unit (Turbo S

only)

|

Bad Intelligent Device Or Component

|

516115

|

12

|

|

Data Valid But Above Normal Operating Range - Least Severe

Level

|

15

|

|

Data Valid But Below Normal Operating Range - Least Severe

Level

|

|

17

|

|

CAN Message PGN 65382

|

Abnormal Update Rate

|

516116

|

9

|

|

CAN Message PGN 65396

|

Abnormal Update Rate

|

516117

|

9

|

|

CAN Message PGN 65314

|

Abnormal Update Rate

|

516118

|

9

|

|

SW Version & HW Version Mismatch

|

Data Erratic, Intermittent Or Incorrect

|

516119

|

2

|

|

CAN Message PGN 65265

|

Abnormal Update Rate

|

516120

|

9

|

|

CAN Message PGN 61445

|

Abnormal Update Rate

|

516121

|

9

|

|

Steering Angle Adoption Offset (Turbo S only)

|

Data Valid But Above Normal Operating Range - Least Severe

Level

|

516122

|

15

|

|

Vehicle Speed Data

|

Data Erratic, Intermittent Or Incorrect

|

516123

|

2

|

|

Data Drifted High

|

20

|

|

Suspension Control Module (Turbo S only)

|

Bad Intelligent Device Or Component

|

516124

|

12

|

|

CAN 1

|

Root Cause Not Known

|

516125

|

11

|

|

System Voltage

|

Data Valid But Above Normal Operational Range - Most Severe

Level

|

516126

|

0

|

|

Data Valid But Below Normal Operational Range - Most Severe

Level

|

1

|

|

Voltage Above Normal, Or Shorted To High Source

|

3

|

|

Voltage Below Normal, Or Shorted To Low Source

|

4

|

|

Data Valid But Above Normal Operating Range - Moderately

Severe Level

|

|

16

|

|

Data Valid But Below Normal Operating Range - Moderately

Severe Level

|

18

|

|

Raw Brake Switch Status

|

Data Erratic, Intermittent Or Incorrect

|

520572

|

2

|

|

Normalized Accelerator Pedal Position

|

Data Erratic, Intermittent Or Incorrect

|

520574

|

2

|

|

Engine Speed Data

|

Data Erratic, Intermittent Or Incorrect

|

524000

|

2

|

|

Steering Angle Input

|

Data Erratic, Intermittent Or Incorrect

|

524114

|

2

|