This INDIAN MOTORCYCLE limited warranty excludes any failures that

are not caused by a defect in material or workmanship. THIS WARRANTY

DOES NOT COVER CLAIMS OF DEFECTIVE DESIGN. This warranty also does

not cover acts of God, accidental damage, normal wear and tear, abuse

or improper handling. This warranty also does not cover any motorcycle,

component, or part that has been altered structurally, modified, neglected,

improperly maintained or used for racing, competition, or purposes

other than for which it was designed.

This warranty excludes damages or failures resulting from: improper

lubrication; improper engine timing; improper fuel; surface imperfections

caused by external stress, heat, cold or contamination; operator error

or abuse; improper component alignment, tension, adjustment or altitude

compensation; snow, water, dirt or other foreign substance ingestion/contamination;

improper maintenance; modified components; use of aftermarket or unapproved

components, accessories, or attachments; unauthorized repairs; or

repairs made after the warranty period expires or by an unauthorized

repair center.

This warranty excludes damages or failures caused by abuse, accident,

fire, or any other cause other than a defect in materials or workmanship

and provides no coverage for consumable components, general wear items,

or any parts exposed to friction surfaces, stresses, environmental

conditions and/or contamination for which they were not designed or

not intended, including but not limited to the following items:

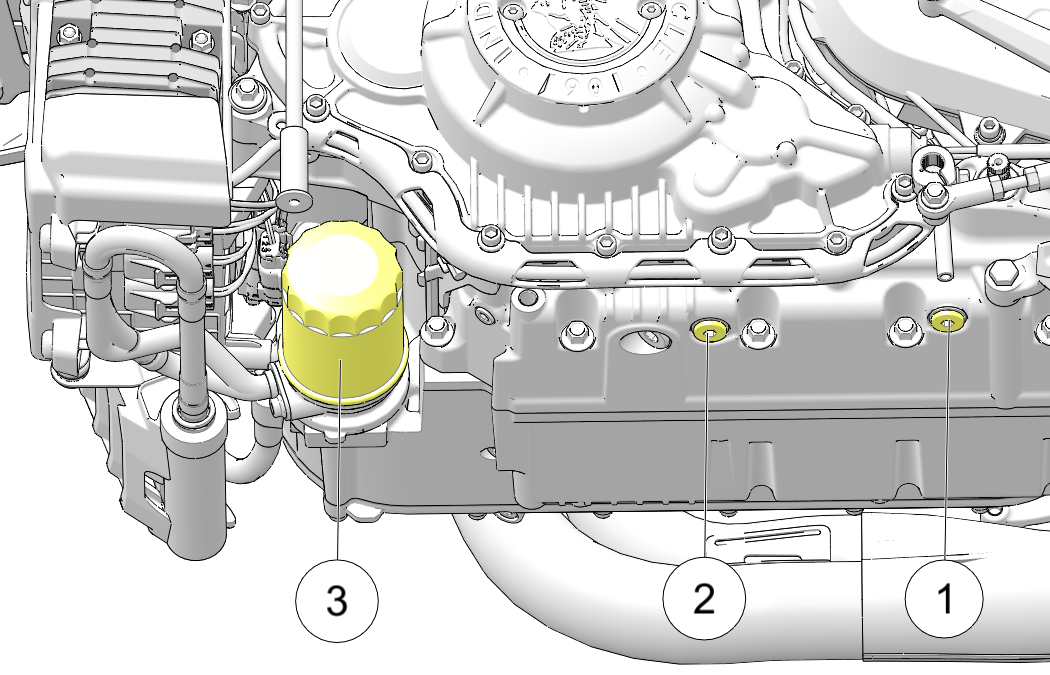

10.10.1.3.1: LUBRICANTS AND FLUIDS

-

Mixing oil brands or using non-recommended oil may cause engine

damage. We recommend the use of INDIAN MOTORCYCLE engine oil.

-

Damage or failure resulting from the use of non-recommended

lubricants or fluids is not covered by this warranty.

This warranty provides no coverage for personal loss or expense,

including mileage, transportation costs, hotels, meals, shipping or

handling fees, motorcycle pick-up or delivery, replacement rentals,

loss of vehicle use, loss of profits, or loss of vacation or personal

time.

The exclusive remedy for breach of this warranty shall be, at INDIAN

MOTORCYCLE’s option, repair or replacement of any defective

materials, components, or products. THE REMEDIES SET FORTH IN THIS

WARRANTY ARE THE ONLY REMEDIES AVAILABLE TO ANY PERSON FOR BREACH

OF THIS WARRANTY. INDIAN MOTORCYCLE SHALL HAVE NO LIABILITY TO ANY

PERSON FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY DESCRIPTION,

WHETHER ARISING OUT OF EXPRESS OR IMPLIED WARRANTY OR ANY OTHER CONTRACT,

NEGLIGENCE, OR OTHER TORT OR OTHERWISE. THIS EXCLUSION OF CONSEQUENTAL,

INCIDENTAL, AND SPECIAL DAMAGES IS INDEPENDENT FROM AND SHALL SURVIVE

ANY FINDING THAT THE EXCLUSIVE REMEDY FAILED OF ITS ESSENTIAL PURPOSE.

THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE IS EXCLUDED

FROM THIS LIMITED WARRANTY. ALL OTHER IMPLIED WARRANTIES (INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTY OF MERCHANTABILITY) ARE LIMITED

IN DURATION TO THE ABOVE TWO YEAR WARRANTY PERIOD. INDIAN MOTORCYCLE

DISCLAIMS ALL EXPRESS WARRANTIES NOT STATED IN THIS WARRANTY. SOME

STATES DO NOT PERMIT THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR ALLOW LIMITATIONS ON THE DURATION OF IMPLIED

WARRANTIES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU IF INCONSISTENT

WITH CONTROLLING STATE LAW.