| Throttle Position Sensor 1 |

51 |

3 |

P0123 |

ON |

This Trouble Code sets if the Throttle Position

Sensor Signal is above 4.39 Volts.

Can be caused by

Damaged Wiring, a faulty Throttle Position Sensor or ECU / Connections. |

| 4 |

P0122 |

This Trouble Code sets if the Throttle Position

Sensor Signal is below 0.7 Volts.

Can be caused by

Damaged Wiring, a faulty Throttle Position Sensor or ECU / Connections. |

| 10 |

P0120 |

This Trouble Code sets when the Throttle Position

Sensor Signal changes too rapidly to be correct. The condition can

be caused by intermittent connections causing the TPS voltage to jump

around between readings. Check for damaged connectors or wiring.

|

| Vehicle Speed Signal |

84 |

2 |

P0503 |

This Trouble Code Sets if the Vehicle Speed

Signal is intermittent or missing.

Can be caused by

Damaged Wiring/Connections or a Faulty / Loose Vehicle Speed Sensor |

| Engine Oil Level Sensor / Switch |

98 |

17 |

P250F |

OFF |

This Trouble Code Sets if the Oil Level is Too

Low.

Can be caused by Low Oil Level, a faulty Oil Level

Sensor or Faulty ECU / Connections. |

| Intake Air Temperature Sensor |

105 |

3 |

P0113 |

ON |

This Trouble Code sets if the Intake Air Temperature

Sensor Signal is above 4.9 Volts.

Can be caused by

Damaged Wiring, a faulty Intake Air Temperature Sensor or ECU / Connections. |

| 4 |

P0112 |

This Trouble Code sets if the Intake Air Temperature

Sensor Signal is below 0.19 Volts.

Can be caused by

Damaged Wiring, a faulty Intake Air Temperature Sensor or ECU / Connections. |

| 10 |

P0114 |

Abnormal Rate of Change. |

| Barometric Pressure Sensor |

108 |

3 |

P2229 |

ON |

This Trouble Code Sets if the Barometric Pressure

Sensor Signal Circuit is Open or Shorted to Battery Voltage.

Can be caused by Damaged Wiring / Connections, a Faulty Ambient

Pressure Sensor or ECU |

| 4 |

P2228 |

This Trouble Code Sets if the Barometric Pressure

Sensor Signal Circuit is Shorted to Ground.

Can be

caused by Damaged Wiring / Connections, a Faulty Ambient Pressure

Sensor or ECU |

| 10 |

P2230 |

This Trouble Code sets if the Barometric Pressure

Sensor Signal indicates an Unrealistic Rate of Change.

Can be caused by Damaged Wiring, a faulty Barometric Pressure Sensor

or ECU / Connections. |

| Engine Temperature Sensor |

110 |

3 |

P0118 |

ON |

This Trouble Code sets if the Engine Coolant

Temperature Sensor Signal is above 4.8 Volts.

Can be

caused by Damaged Wiring, a faulty Coolant Temperature Sensor or ECU

/ Connections. |

| 4 |

P0117 |

This Trouble Code sets if the Engine Coolant

Temperature Sensor Signal is below 0.1 Volts.

Can

be caused by Damaged Wiring, a faulty Coolant Temperature Sensor or

ECU / Connections. |

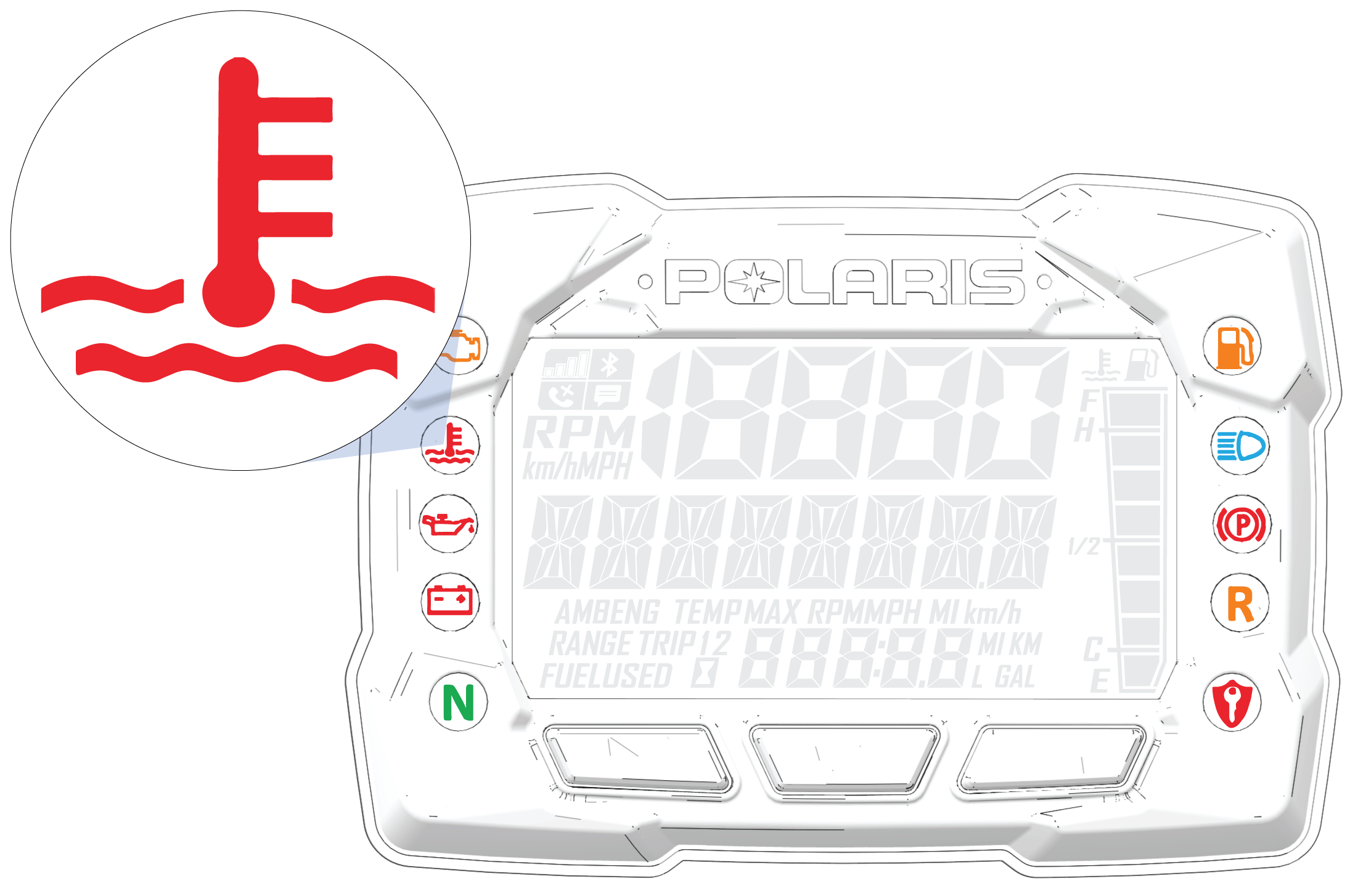

| 0 |

P1217 |

OFF |

This Trouble Code sets if the Engine Temperature

indicates a Critical Over Temperature Condition and the engine is

running in a limp-home mode to prevent damage.

Can

be caused by any failure that would cause the engine to overheat. |

| 16 |

P0217 |

This Trouble Code sets if the Engine Temperature

indicates a Severe Over Temperature Condition.

Can

be caused by any failure that would cause the engine to overheat.

This Trouble Code Does Not indicate a problem with the Engine Temperature

Sensor. |

| 15 |

P1116 |

This Trouble Code sets if the Engine Temperature

indicates an Over Temperature Condition.

Can be caused

by any failure that would cause the engine to overheat. This Trouble

Code Does Not indicate a problem with the Engine Temperature Sensor. |

| DC Chassis Voltage |

167 |

3 |

P1569 |

ON |

This Trouble Code sets if the System Voltage

is above an acceptable level.

Can be caused by Damaged

Wiring, a Faulty Voltage Regulator or Faulty ECU. |

| 4 |

P1568 |

This Trouble Code sets if the System Voltage

is below an acceptable level.

Can be caused by Damaged

Wiring, a faulty stator, Faulty Voltage Regulator or Faulty ECU. |

| Exhaust Temperature Sensor |

173 |

3 |

P0546 |

ON |

This Trouble Code sets if the engine has been

running above 3000 RPM for more than 2 minutes and the Exhaust Temperature

Sensor Signal is above 4.90 Volts.

Can be caused by

Damaged Wiring, a faulty Engine Temperature Sensor or ECU / Connections. |

| 4 |

P0545 |

This Trouble Code sets if the engine has been

running above 3000 RPM for more than 2 minutes and the Exhaust Temperature

Sensor Signal is below 0.06 Volts.

Can be caused by

Damaged Wiring, a faulty Engine Temperature Sensor or ECU / Connections. |

| 0 |

P1517 |

This Trouble Code Sets if the Engine was Shut

Down due to High Exhaust Temperature.

Can be caused

by a Faulty Exhaust Temperature Sensor / Connections or Lean Air /

Fuel Ratio causing high exhaust temperature. |

| 10 |

P1546 |

Abnormal rate of change. |

| ECU Memory Checksum Error |

628 |

13 |

P0601 |

OFF |

This Trouble Code Sets if an Internal Memory

Fault is detected in the Engine Controller

Can only

be caused by a defective ECU. |

| Crankshaft Sensor Signal Fault |

636 |

2 |

P0335 |

OFF |

This Trouble Code sets if the Engine is Running

and No Signal is Detected from the 5X Crankshaft Sensor.

Can be caused by Damaged Wiring, a faulty Crankshaft Sensor or ECU

/ Connections. |

| Crankshaft Position Sensor Circuit Fault |

636 |

8 |

P0336 |

OFF |

This Trouble Code sets if the Engine is Running

and the number of pulses from the 5X Crankshaft Sensor is not correct.

Can be caused by Damaged Wiring, a faulty Crankshaft Sensor

or ECU / Connections. |

| Fuel Injector (MAG) |

651 |

5 |

P0261 |

ON |

This Trouble Code sets if an Open Circuit Condition

is detected in the MAG Cylinder Port Injector Control Circuit.

Can be caused by Damaged Wiring, a faulty Fuel Injector or ECU /

Connections. |

| 3 |

P0262 |

This Trouble Code sets if a Short to Voltage

is detected in the MAG Cylinder Port Injector Control Circuit.

Can be caused by Damaged Wiring, a faulty Fuel Injector or ECU /

Connections. |

| Fuel Injector (PTO) |

652 |

5 |

P0264 |

ON |

This Trouble Code sets if an Open Circuit Condition

is detected in the PTO Cylinder Port Injector Control Circuit.

Can be caused by Damaged Wiring, a faulty Fuel Injector or ECU /

Connections. |

| 3 |

P0265 |

This Trouble Code sets if a Short to Voltage

is detected in the PTO Cylinder Port Injector Control Circuit.

Can be caused by Damaged Wiring, a faulty Fuel Injector or ECU /

Connections. |

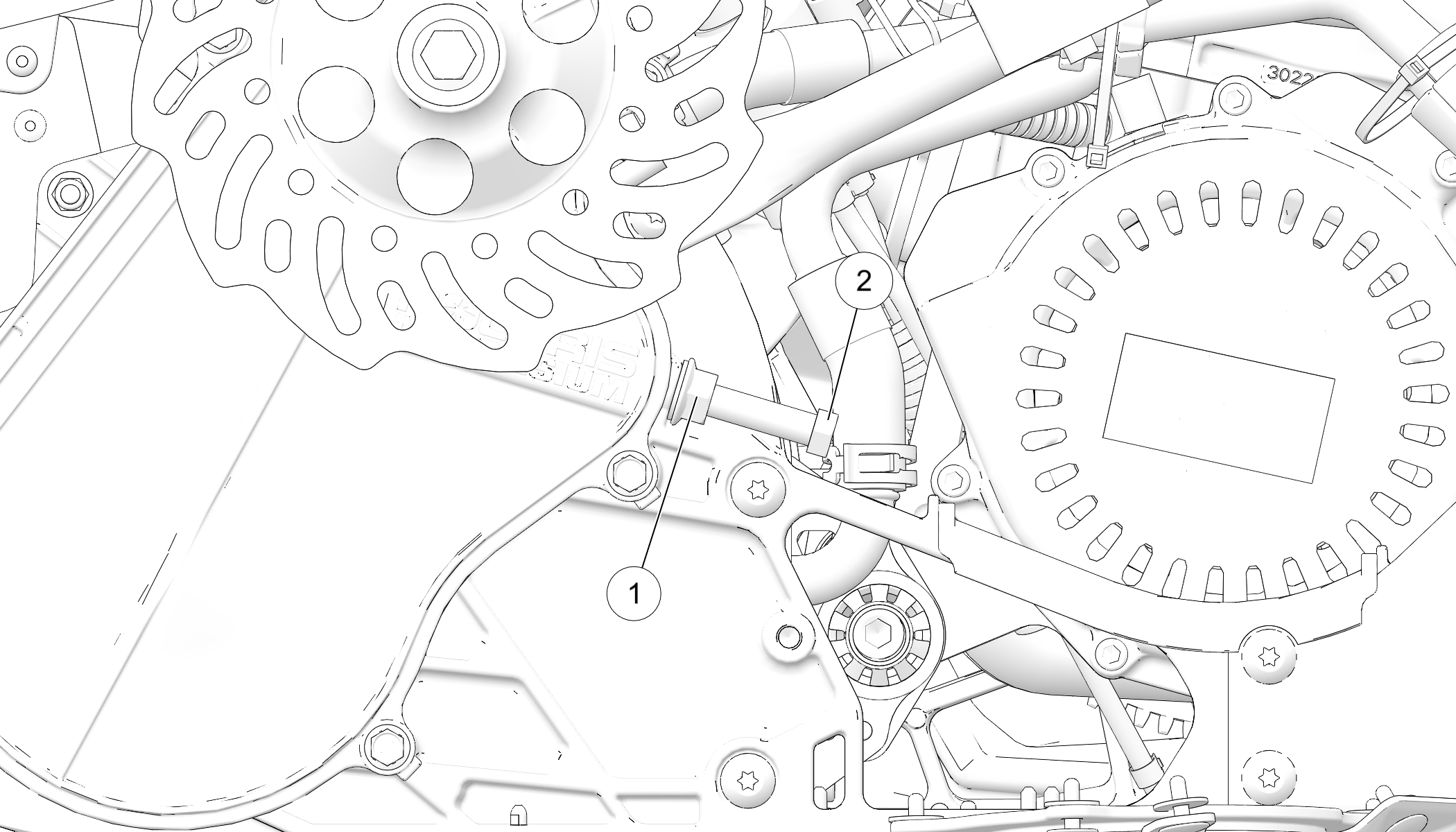

| Knock Sensor |

731 |

4 |

P0327 |

ON |

This Trouble Code sets if the Engine Speed is

above 6000 RPM and the Detonation Sensor Signal is below 1.23 Volts

for more than 2 seconds.

Can be caused by Damaged Wiring,

a faulty Detonation Sensor or ECU / Connections. |

| 2 |

P0325 |

This Trouble Code Sets if the Knock Sensor Signal

indicates an Unrealistic Value.

Can be caused by a

Faulty Knock Sensor / Connections, a Loose Sensor or Excessive Engine

Mechanical Noise. |

| Ignition Coil Primary Driver (MAG) |

1268 |

5 |

P1351 |

ON |

This Trouble Code Sets if the Ignition Coil

Driver Circuit is Open.

Can be caused by Damaged Wiring

/ Connections, a Ignition Coil or ECU |

| Fuel Pump Driver Circuit |

1347 |

5 |

P0230 |

ON |

This Trouble Code Sets if the Fuel Pump Relay

Driver Circuit is Open.

Can be caused by Damaged Wiring

/ Connections, a Faulty Fuel Pump or ECU. |

| Knock (DET) Level (MAG) |

1352 |

0 |

P1336 |

ON |

This Trouble Code Sets if the Engine Controller

Reaches the Maximum Detonation Control Limit by Fuel Correction on

the Mag Cylinder |

| 16 |

P2336 |

This Trouble Code Sets if Cylinder 1 (MAG) Knock

Sensor reaches a Critical Level. Can be caused by Excessive Knock

(Fuel Problems), a Lean Running Condition or Engine Mechanical Problems. |

| Knock (DET) Level (PTO) |

1353 |

0 |

P1337 |

ON |

This Trouble Code Sets if the Engine Controller

Reaches the Maximum Detonation Control Limit by Fuel Correction on

the PTO Cylinder. |

| 16 |

P2337 |

This Trouble Code Sets if Cylinder 2 (PTO) Knock

Sensor reaches a Critical Level. Can be caused by Excessive Knock

(Fuel Problems), a Lean Running Condition or Engine Mechanical Problems. |

Sensor Supply Voltage 1

(TPS

/ TMAP) |

3509 |

4 |

P06B1 |

ON |

This Trouble Code sets if the Sensor Supply

1 Voltage is below an acceptable limit (4.50 Volts). Can be caused

by Damaged Wiring or Faulty / Shorted Sensors. |

Sensor Supply Voltage 2

(Speed

Sensor) |

3510 |

4 |

P06B4 |

OFF |

This Trouble Code sets if the Sensor Supply

2 Voltage is below an acceptable limit (4.50 Volts). Can be caused

by Damaged Wiring or Faulty / Shorted Sensors. |

| Electronic Oil Pump |

3589 |

5 |

P16BA |

ON |

This Trouble Code Sets if the Oil Pump Driver

Circuit is Open.

Can be caused by Damaged Wiring /

Connections, a Faulty Oil Pump/Connections or Faulty ECU / Connections. |

| 12 |

P16BC |

This Trouble Code Sets if a Failure is Detected

in the Oil Pump Driver Circuit.

Can be caused by Damaged

Wiring / Connections, a Faulty Oil Pump/Connections or Faulty ECU

/ Connections. |

ECU Output Supply Voltage

Fuel Injector Power (16V) |

3598 |

3 |

P16A9 |

ON |

This Trouble Code sets if the Injector Output

Supply 2 Voltage is above an acceptable limit. Can be caused by Damaged

Wiring or Faulty / Shorted Connectors. |

| 4 |

P16A8 |

This Trouble Code sets if the Injector Output

Supply 2 Voltage is below an acceptable limit. Can be caused by Damaged

Wiring or Faulty / Shorted Connectors. |

ECU Output Supply Voltage

Ground Speed Sensor (5V) |

3599 |

3 |

P17AA |

ON |

This Trouble Code Sets if the ECU Output Supply

Voltage #3 (Vehicle Speed Sensor Supply) is Too High. Can be caused

by Damaged Wiring / Connections, a Faulty Vehicle Speed Sensor / Connections

or Faulty ECU / Connections. |

| 4 |

P17AB |

This Trouble Code Sets if the ECU Output Supply

Voltage #3 (Vehicle Speed Sensor Supply) is Too Low. Can be caused

by Damaged Wiring / Connections, a Faulty Vehicle Speed Sensor / Connections

or Faulty ECU /Connections. |

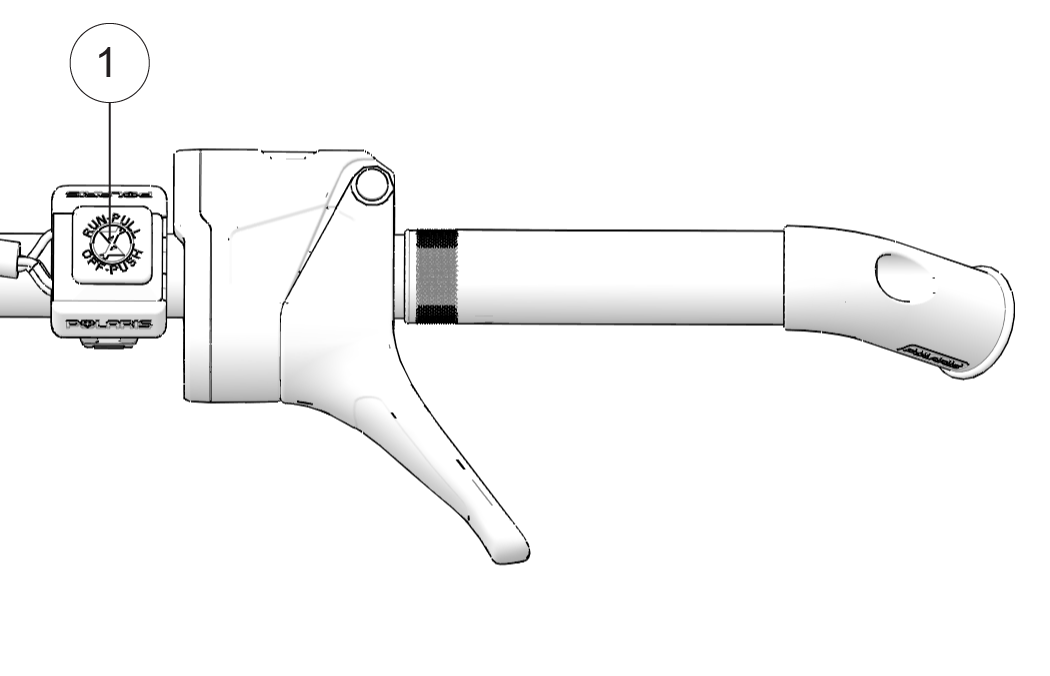

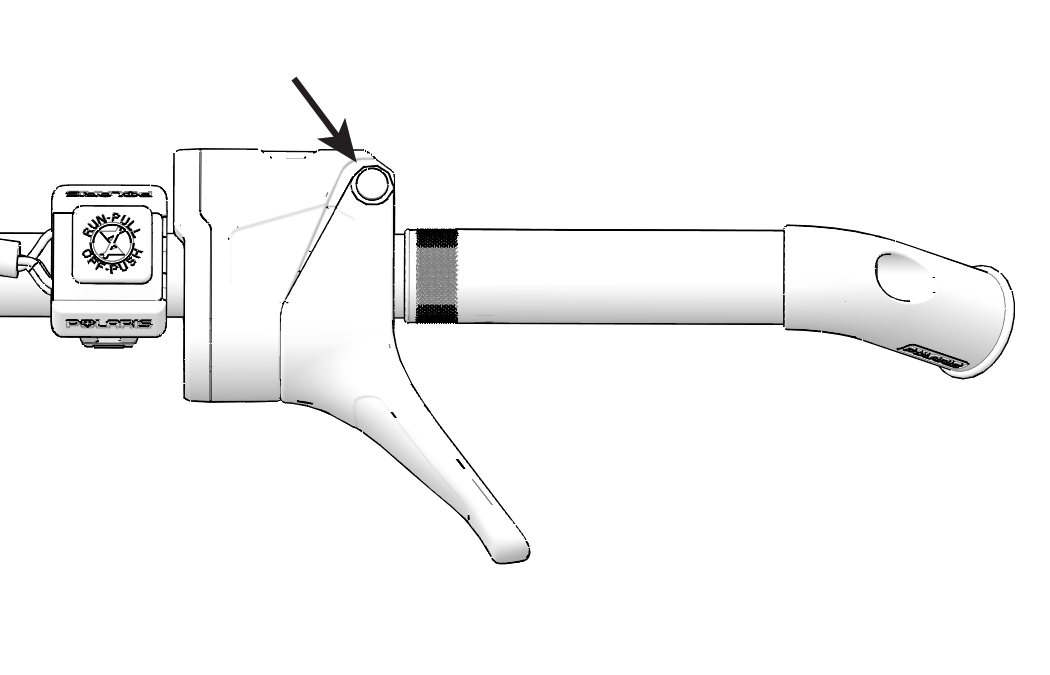

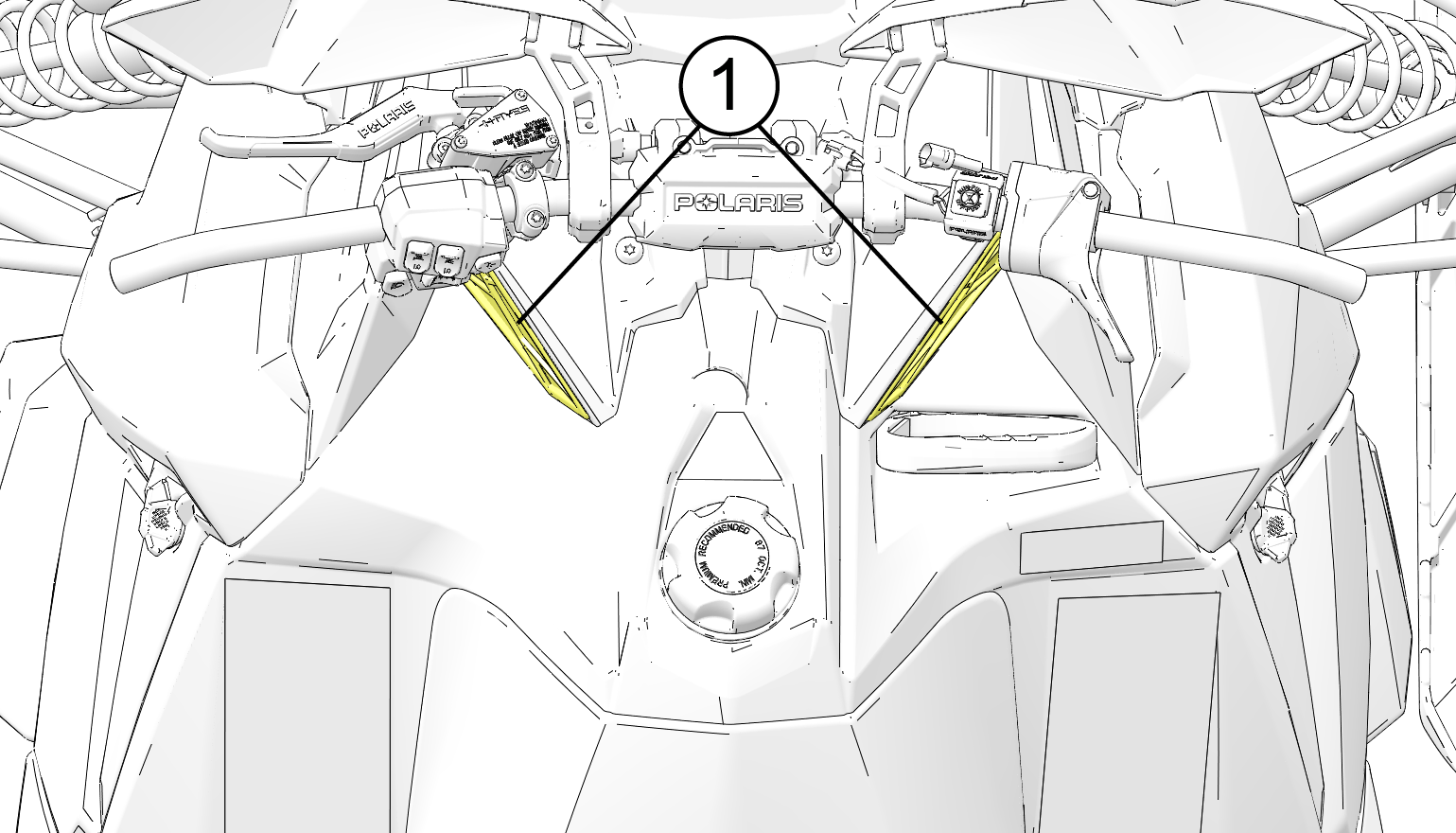

| Throttle Release Signal |

520194 |

3 |

P1555 |

ON |

This Trouble Code Sets if the Throttle Release

Switch Signal is Open Circuit or Shorted to Battery Voltage. Can

be caused by Damaged Wiring / Connections, a Faulty Throttle Safety

Switch or ECU. |

| 4 |

P1554 |

This Trouble Code Sets if the Throttle Safety

Switch Signal is Shorted to Ground. Can be caused by Damaged Wiring

/ Connections, a Faulty Throttle Safety Switch or ECU. |

| 7 |

P1552 |

This Trouble Code Sets if the Throttle Release

Switch Signal Indicates a Throttle Stuck Open. Can be caused by a

Stuck Throttle or Mis-adjusted / Stuck Throttle Linkage. |

| Exhaust Valve Solenoid |

520215 |

5 |

P1477 |

ON |

This Trouble Code sets if an Short to Voltage

Condition is detected in the Exhaust Valve Solenoid Control Circuit.

Can be caused by Damaged Wiring, a faulty Exhaust Valve Solenoid

or ECU / Connections. |

| 3 |

P1479 |

This Trouble Code sets if an Short to Voltage

Condition is detected in the Exhaust Valve Solenoid Control Circuit.

Can be caused by Damaged Wiring, a faulty Exhaust Valve Solenoid

or ECU / Connections. |

| Load Shed Relay |

520219 |

5 |

P1646 |

ON |

This Trouble Code Sets if the Load Shed Relay

Driver Circuit is Open. Can be caused by Damaged Wiring / Connections,

a Accessory Ignition Relay or ECU. |

| 3 |

P1647 |

This Trouble Code Sets if the Load Shed Relay

Driver Circuit is Shorted to Voltage. Can be caused by Damaged Wiring

/ Connections, a Faulty Accessory Relay or ECU. |

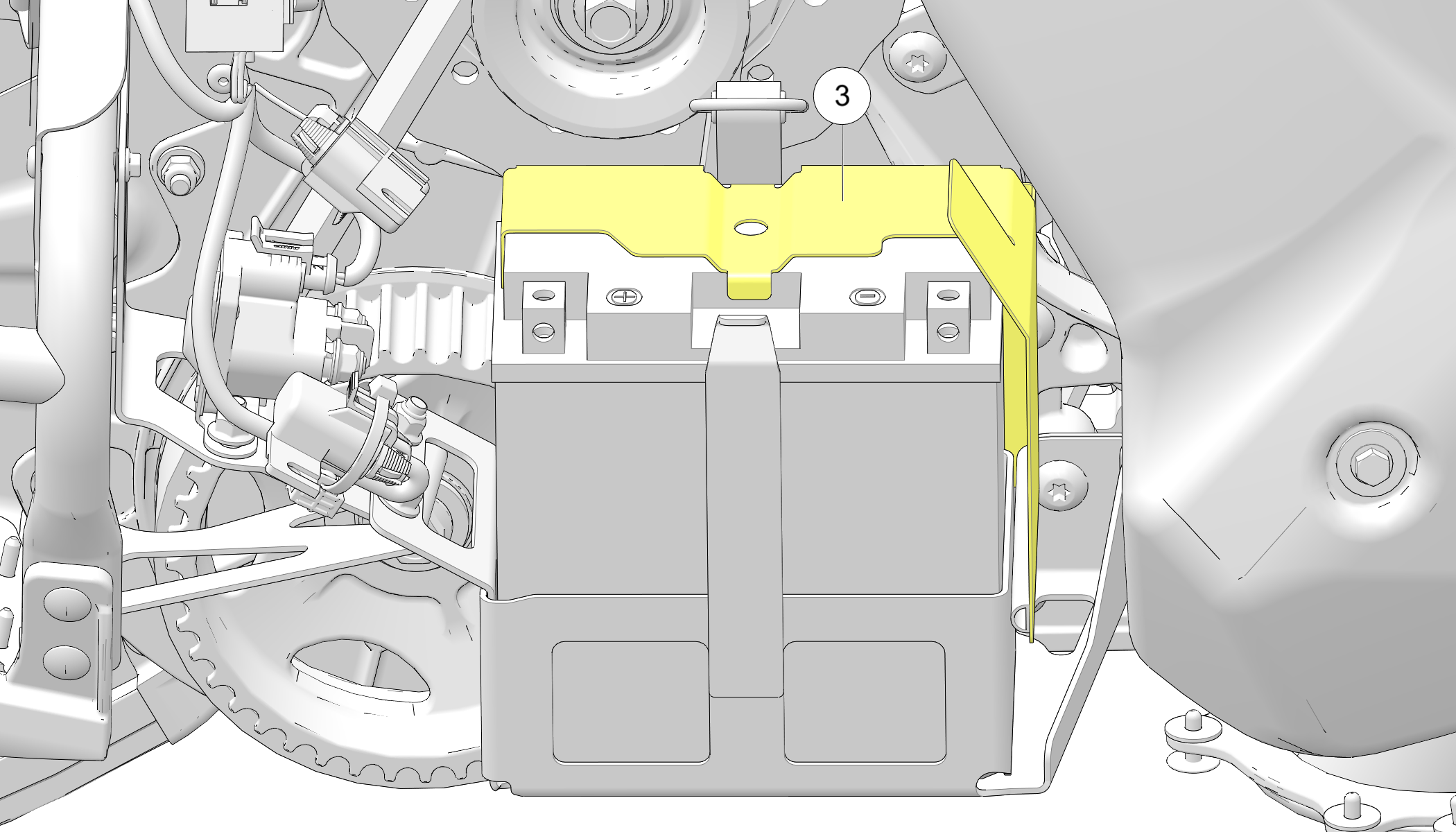

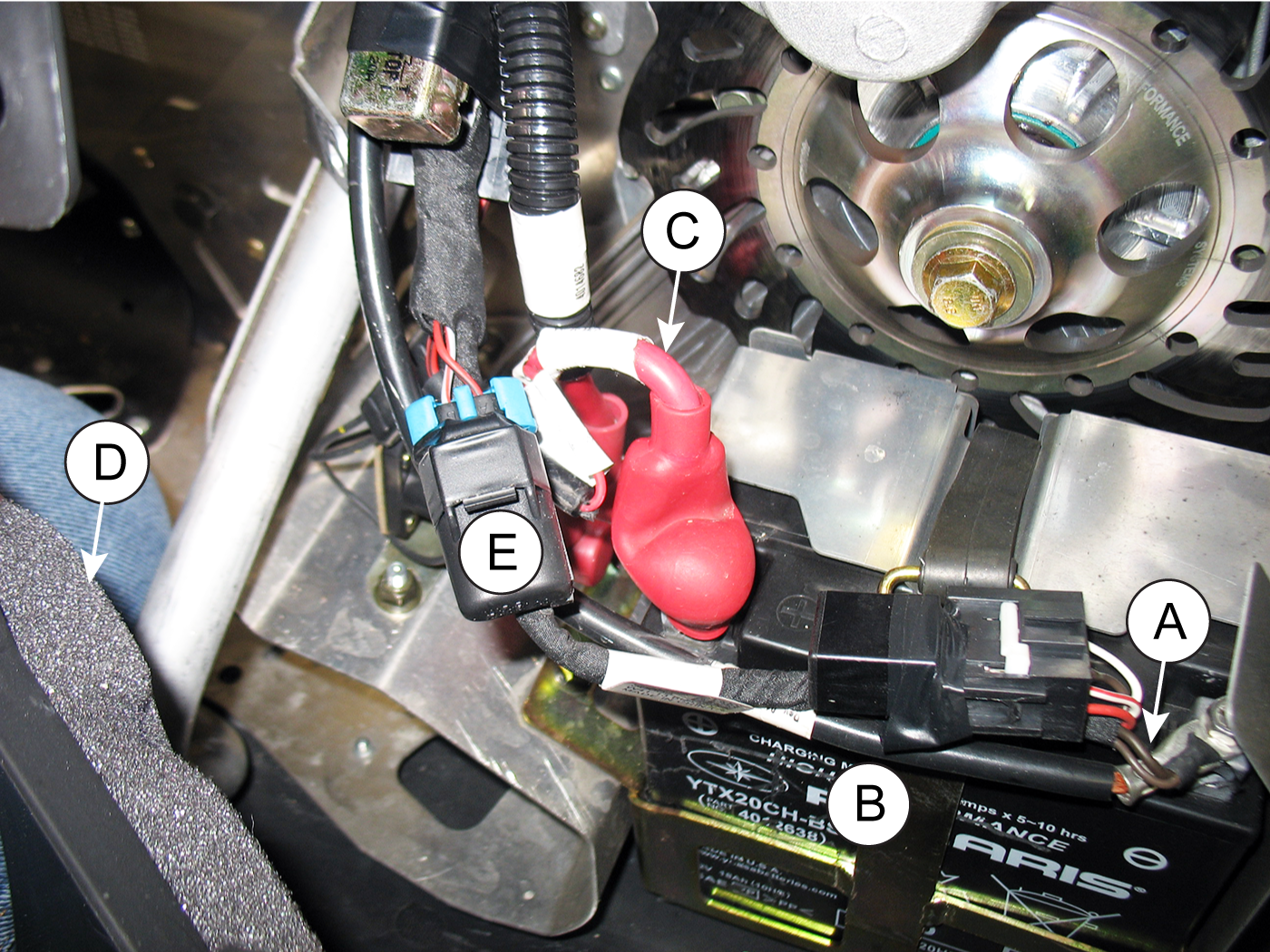

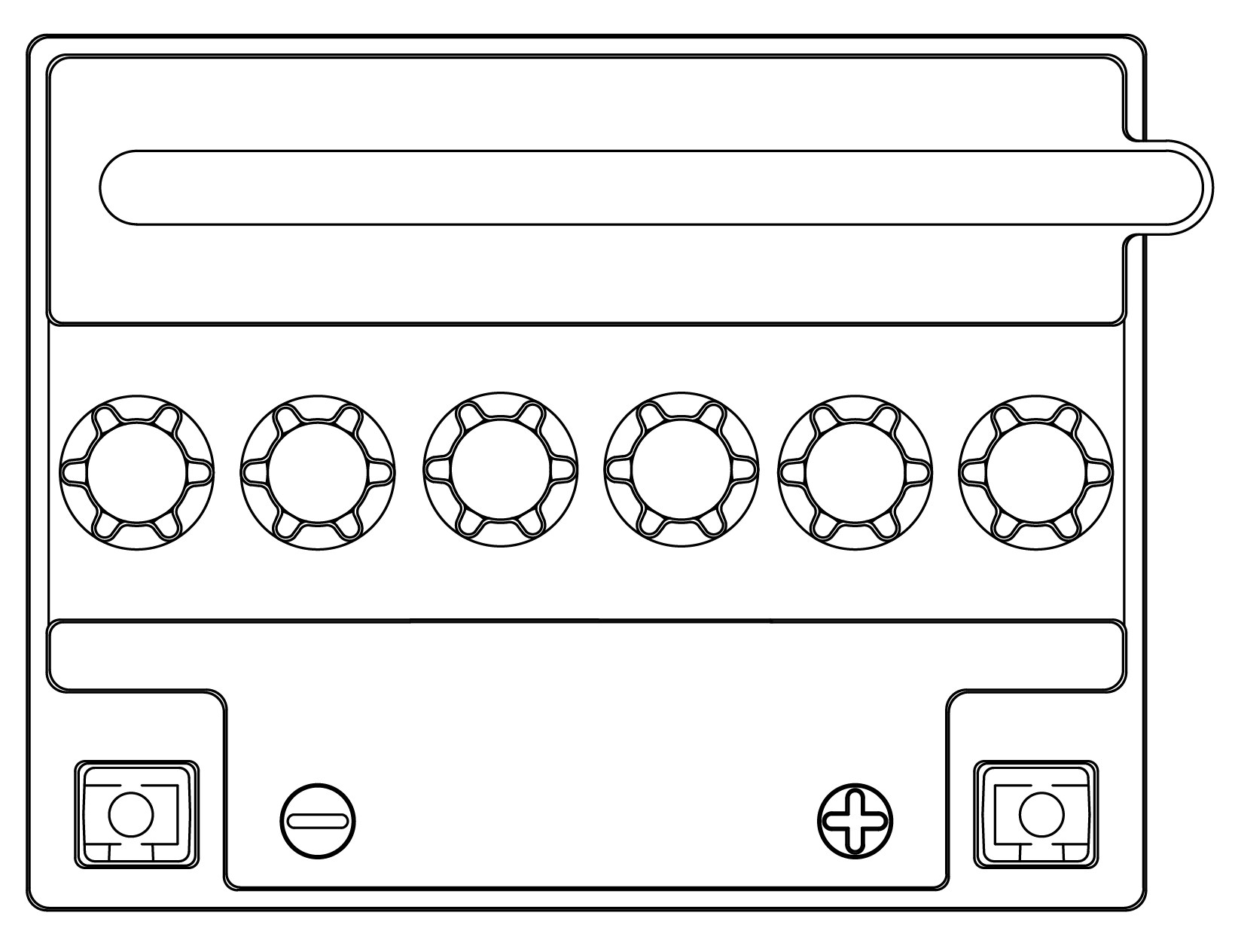

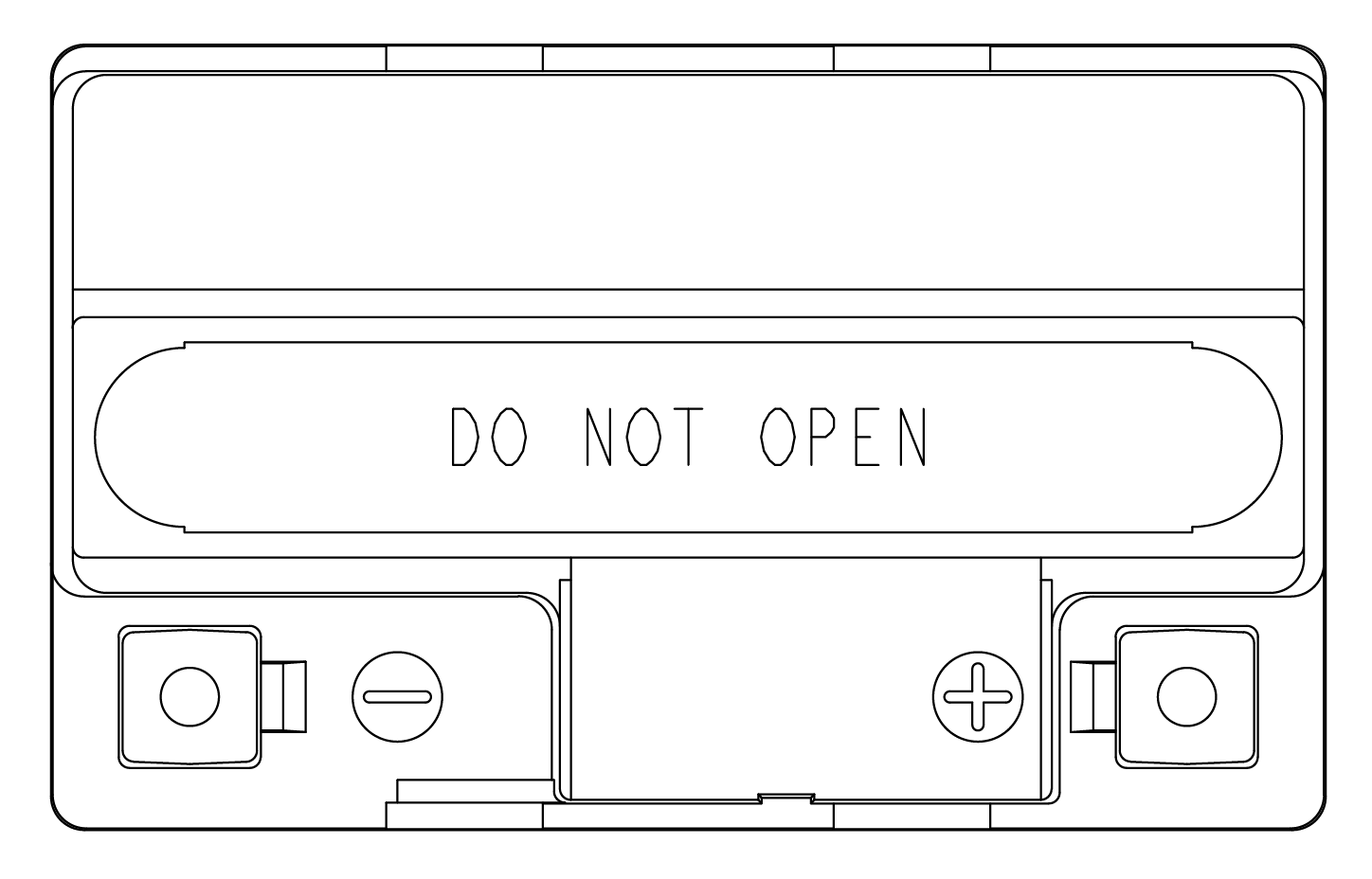

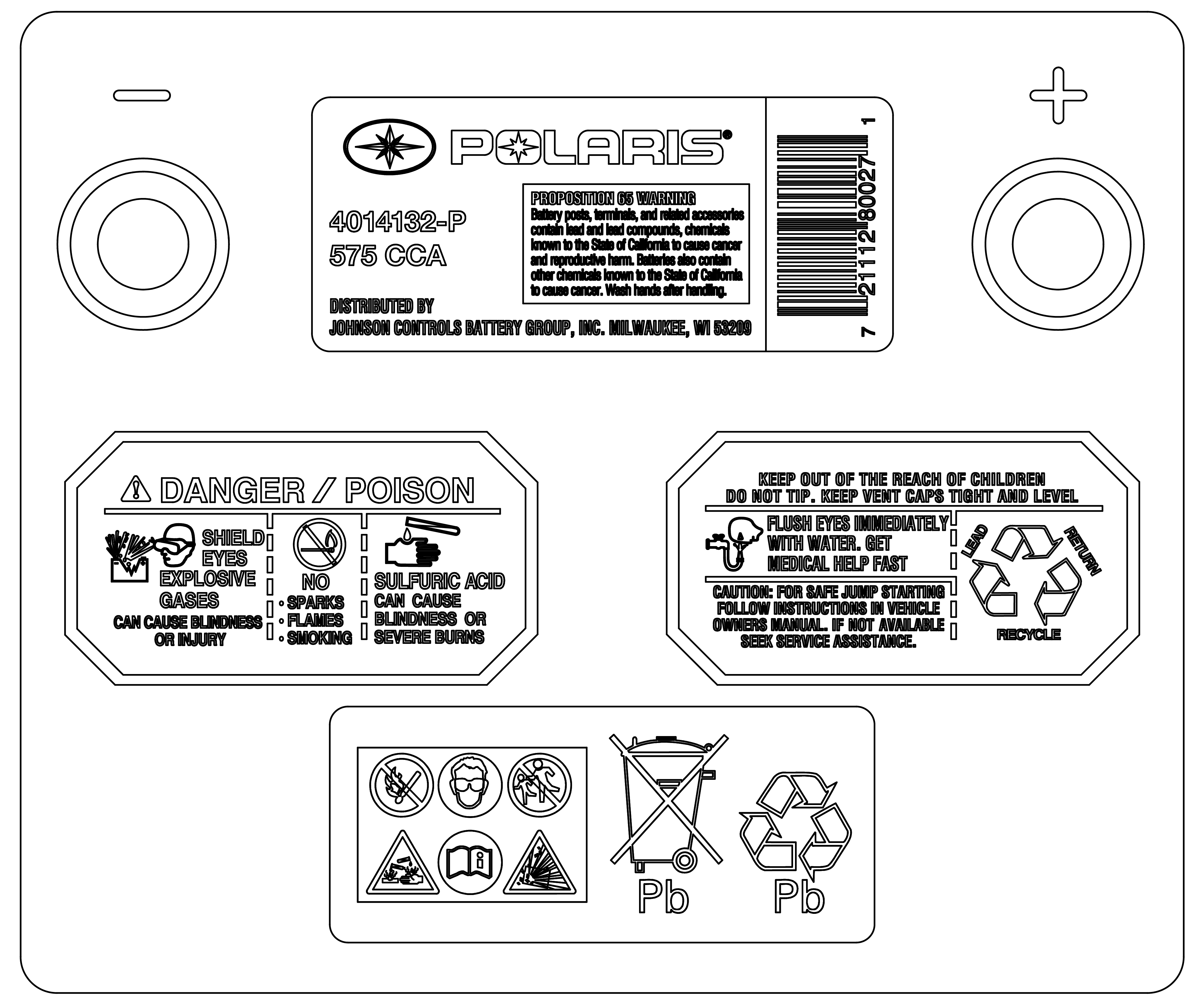

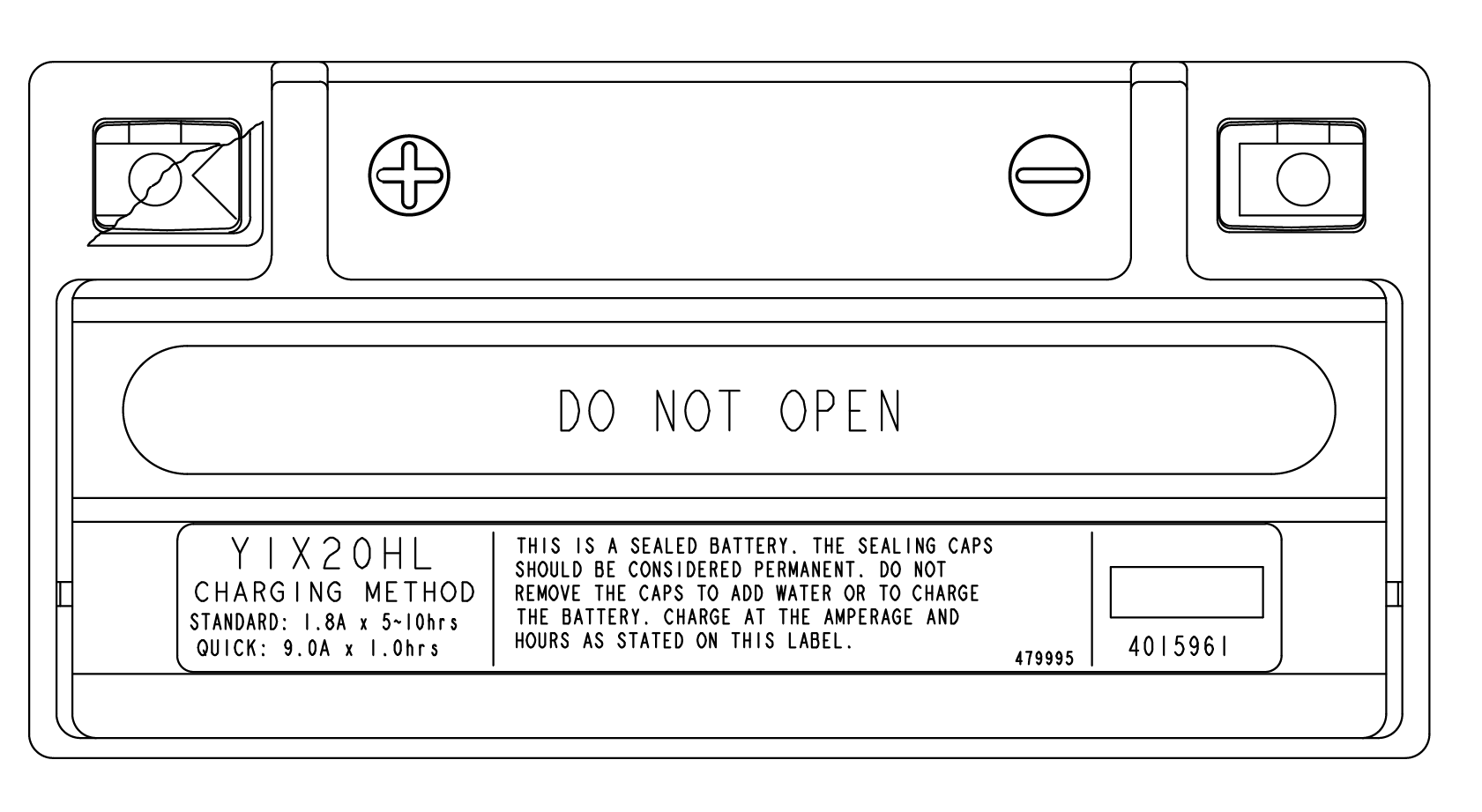

Battery Charge Relay

Battery-Equipped Models Only |

520220 |

5 |

P163C |

ON |

This Trouble Code Sets if the Charge Relay Driver

Circuit is Open. Can be caused by Damaged Wiring / Connections, a

Charge Relay or ECU. |

| 3 |

P163D |

This Trouble Code Sets if the Charge Relay Driver

Circuit is Shorted to Voltage. Can be caused by Damaged Wiring /

Connections, a Faulty Charge Relay or ECU. |

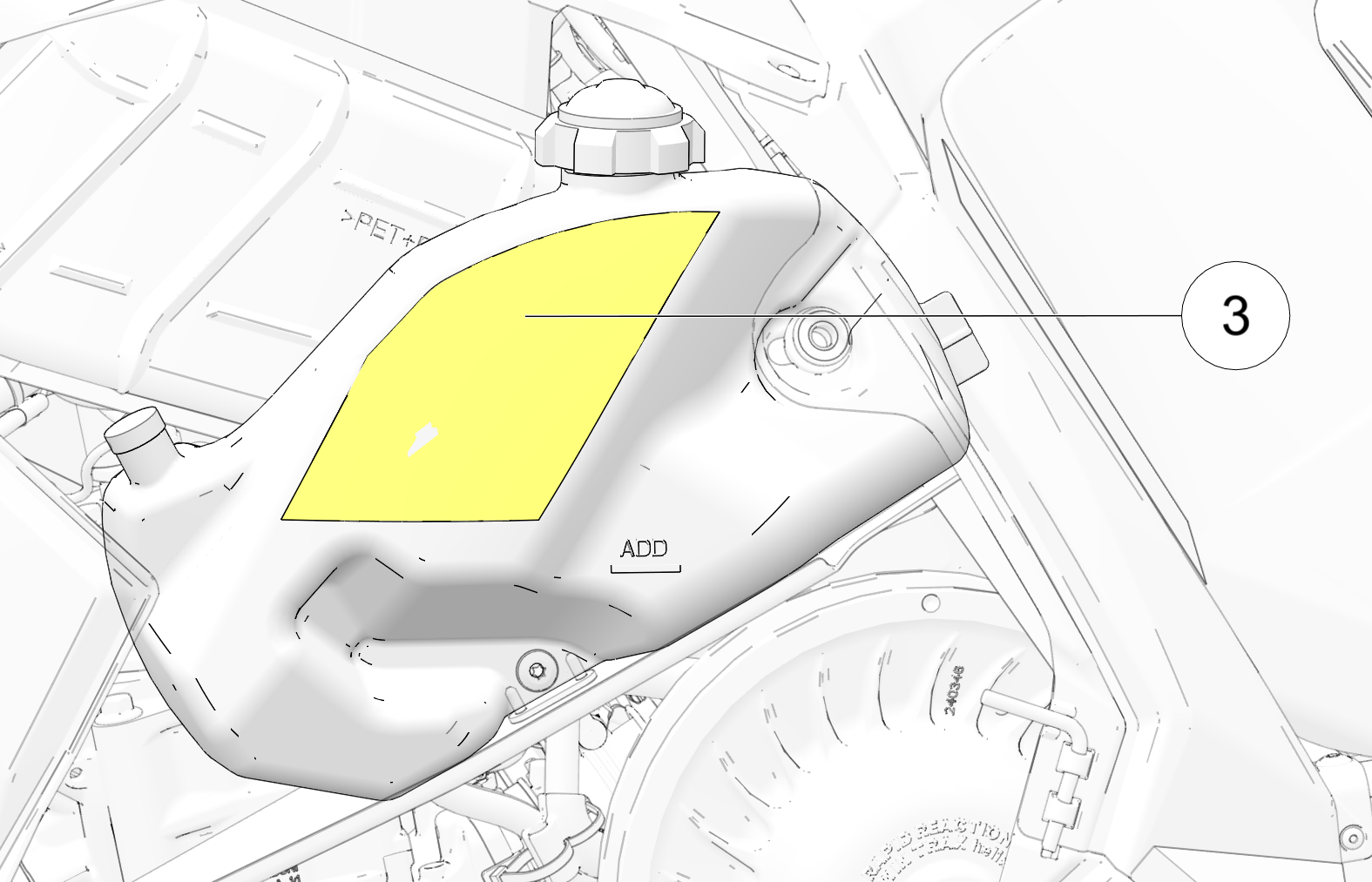

| Oil Pump or Fuel Injector Settings Not Programmed |

520241 |

13 |

P1278 |

ON |

This Trouble Code Sets if Either the Fuel Injector

or Oil Injection Pump Calibration has Not Been Programmed. Update

the Injector/Oil Pump Settings.

WARNING: Do Not

Operate the Vehicle with This Trouble Code Set.

|

| Ground Speed Pulses per Mile Not Programmed |

520242 |

13 |

P1279 |

ON |

This Trouble Code Sets if the Vehicle Speed

Sensor Setting is Not Properly Programmed in the ECU. Reflash ECU. |

| EV Actuator / Gauge

Relay |

520328 |

5 |

P140D |

ON |

For all E-VES Diagnostic

Trouble Codes (DTCs), see: E-VES Diagnostic Trouble Codes (DTCs)

|

| 3 |

P140E |

| Riding With Brakes on Moderately

Severe |

520555 |

31 |

C2418 |

ON |

Brakes are applied

too long above certain engine rpm. |

| Riding With Brakes on Most Severe |

520556 |

C2419 |

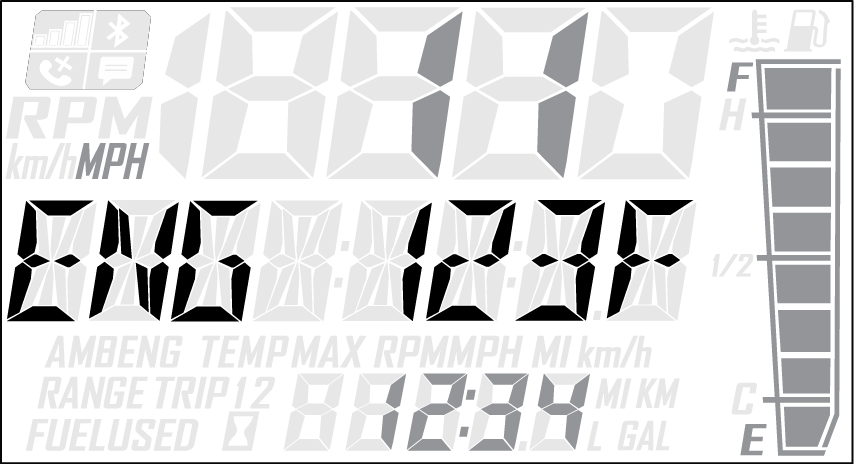

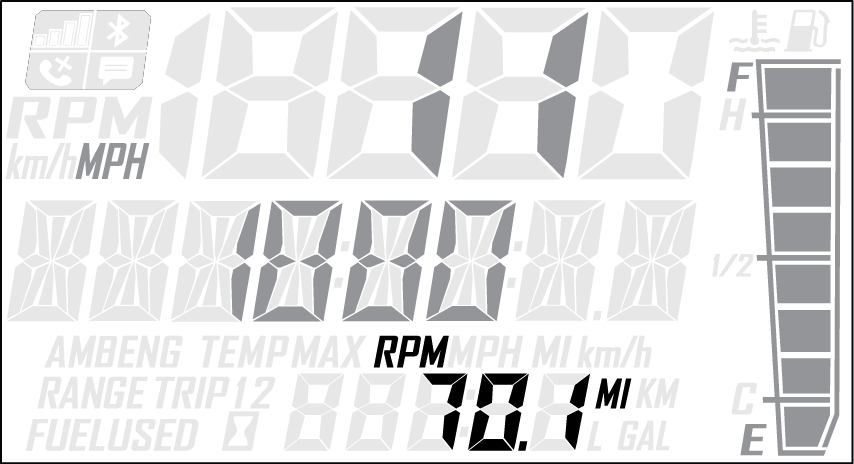

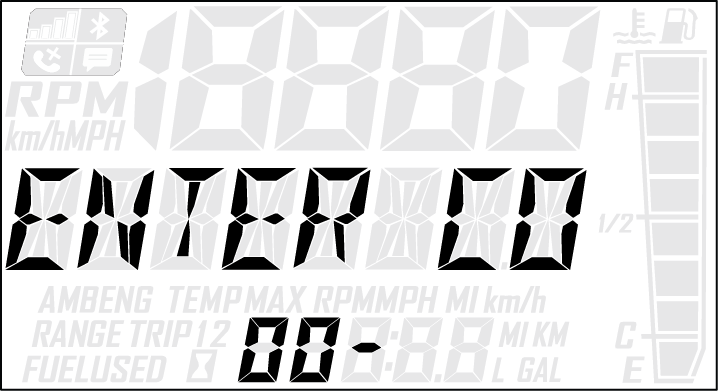

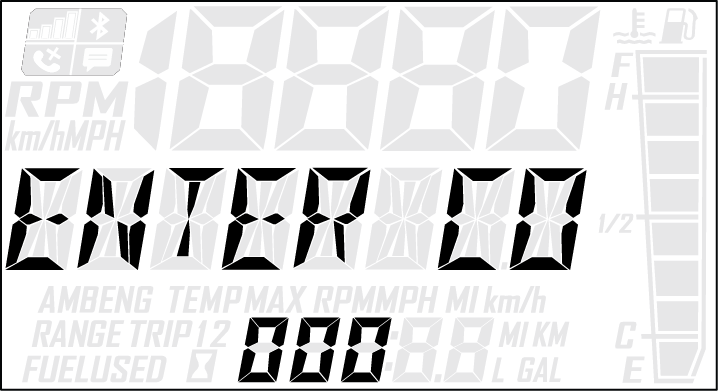

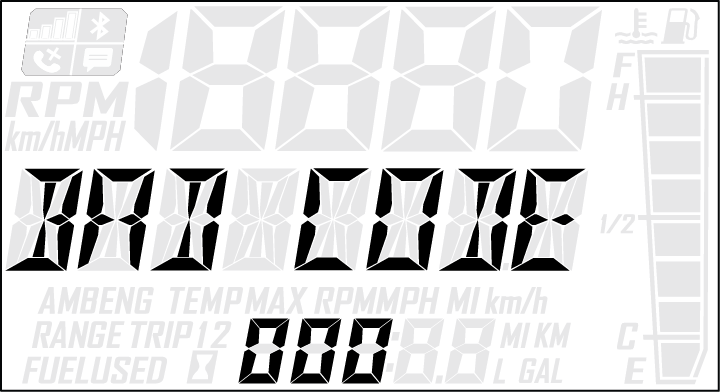

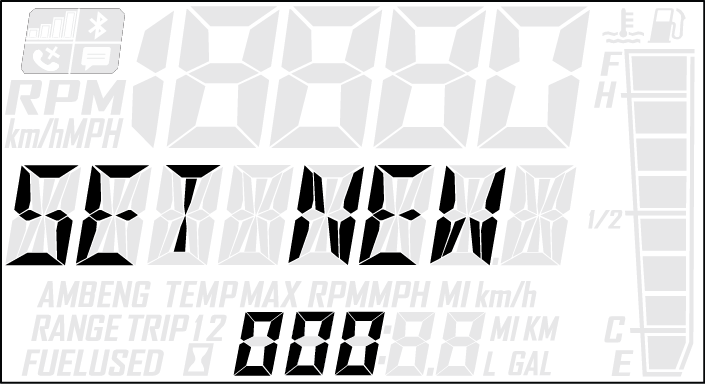

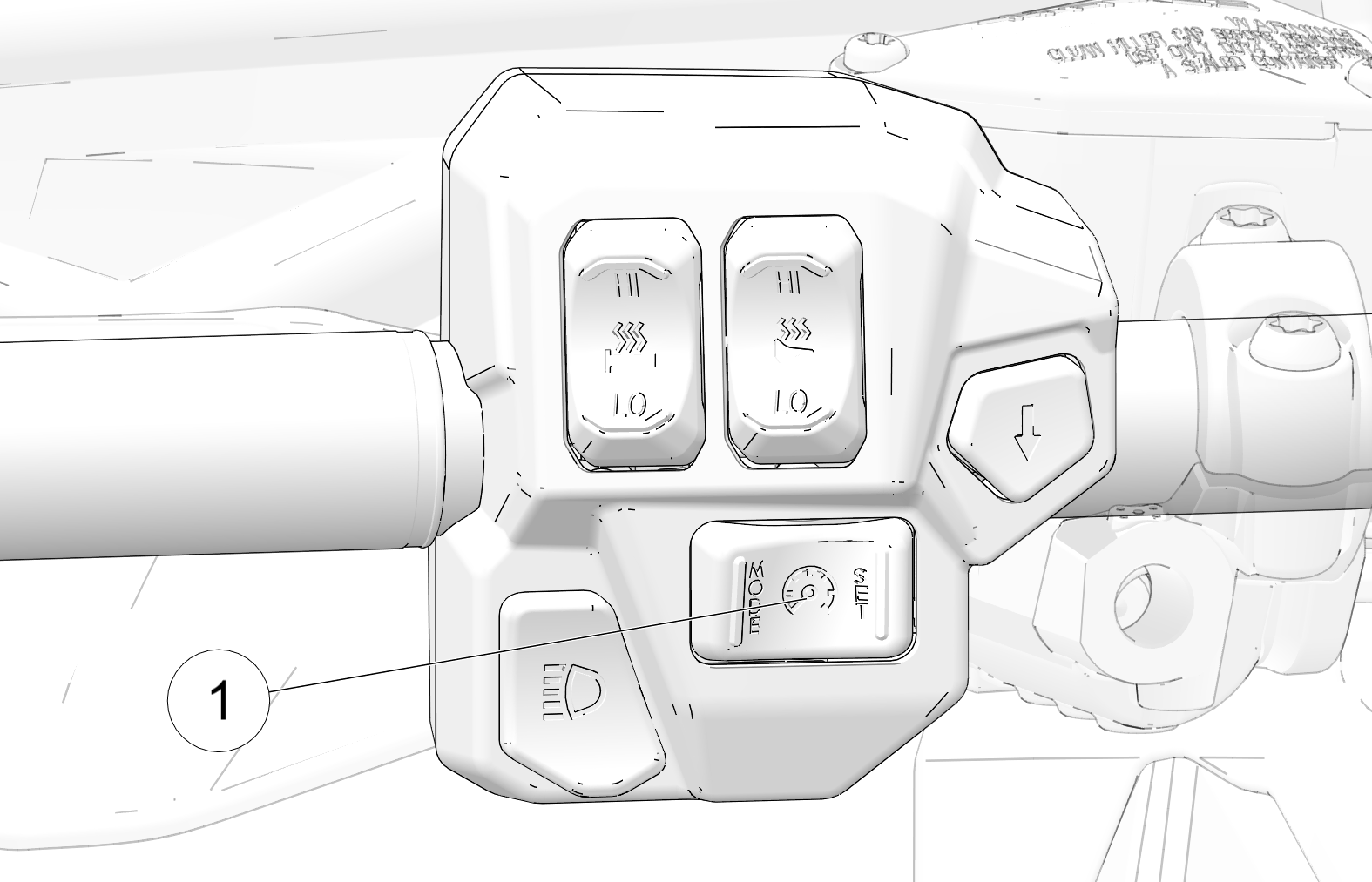

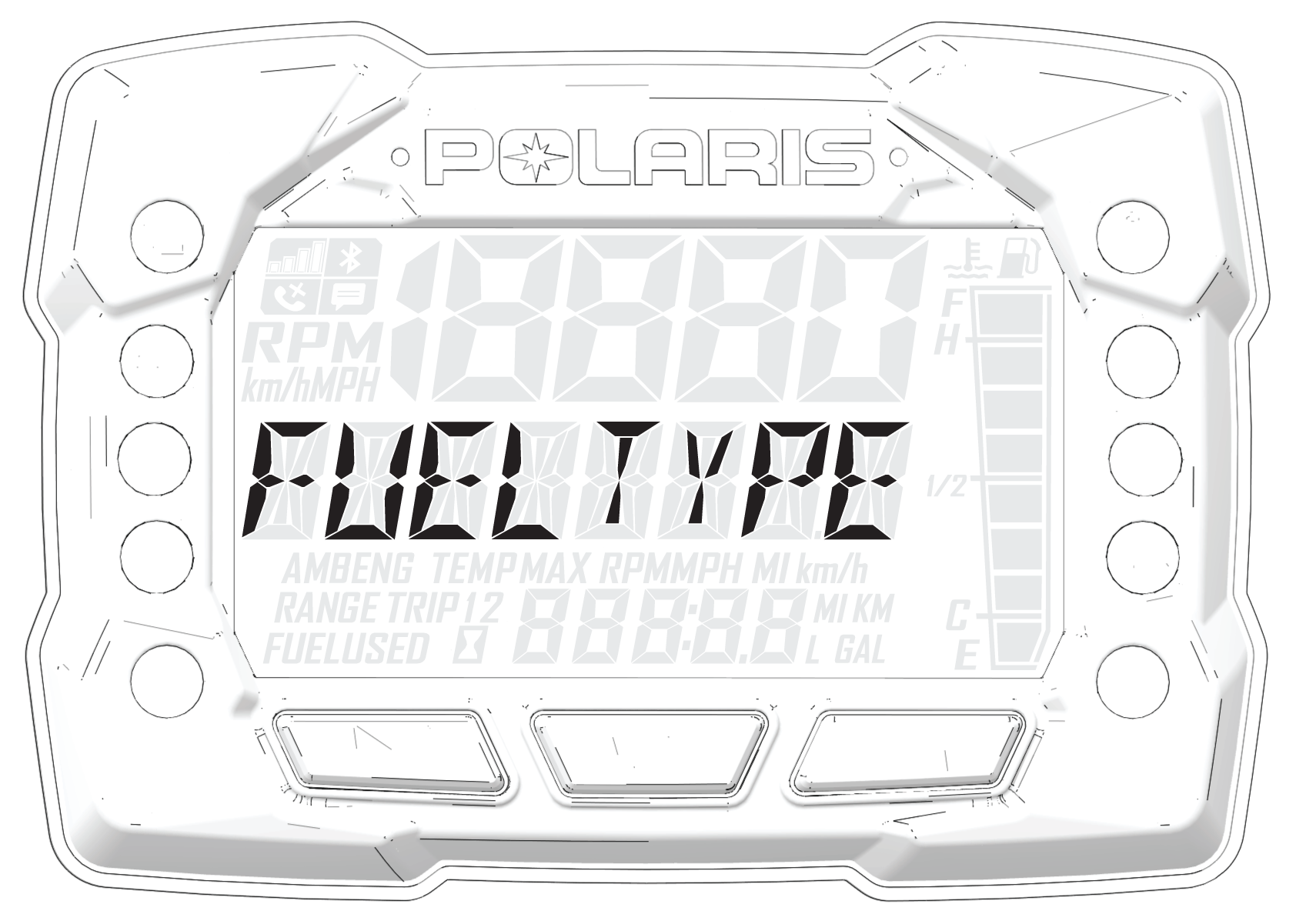

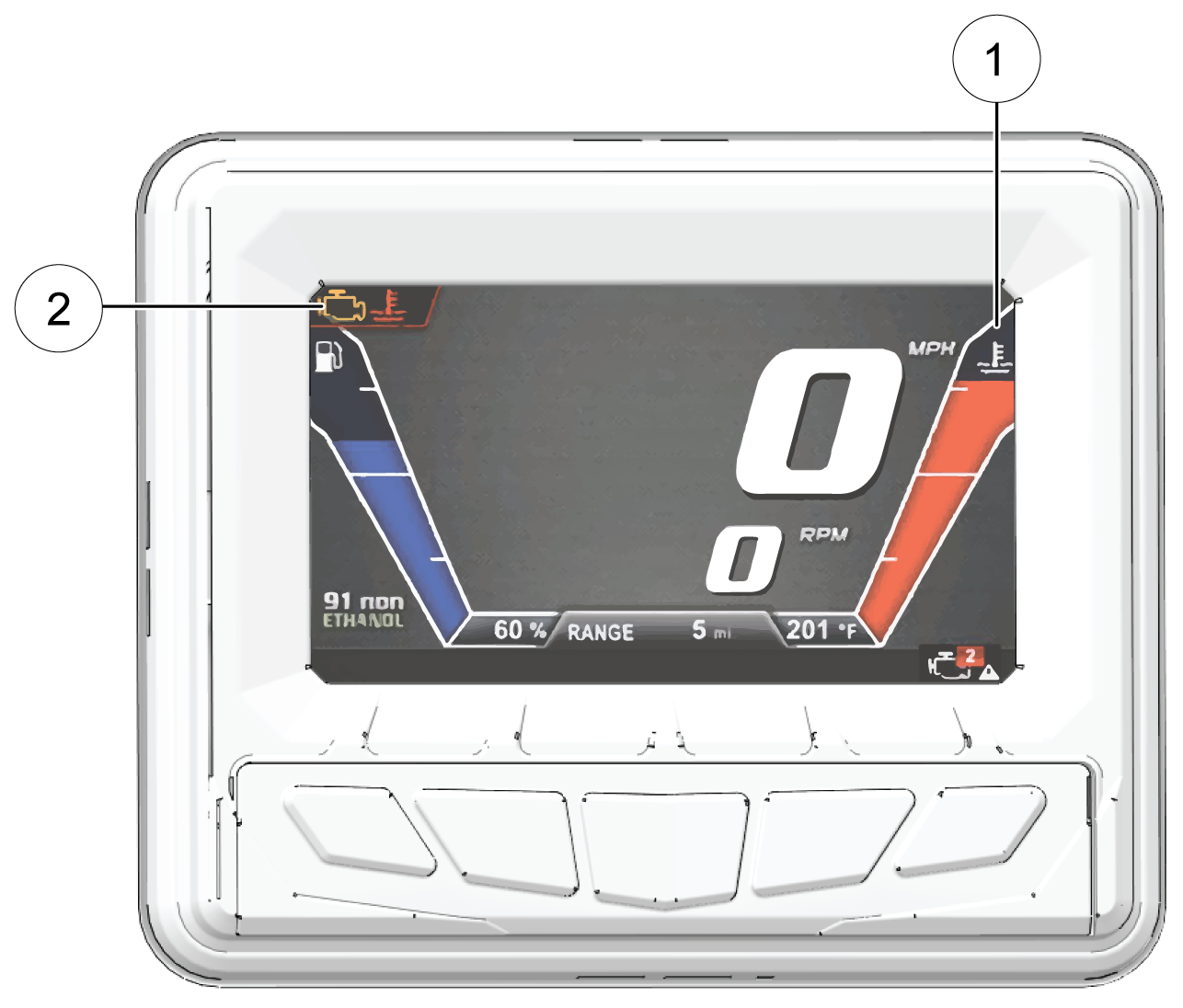

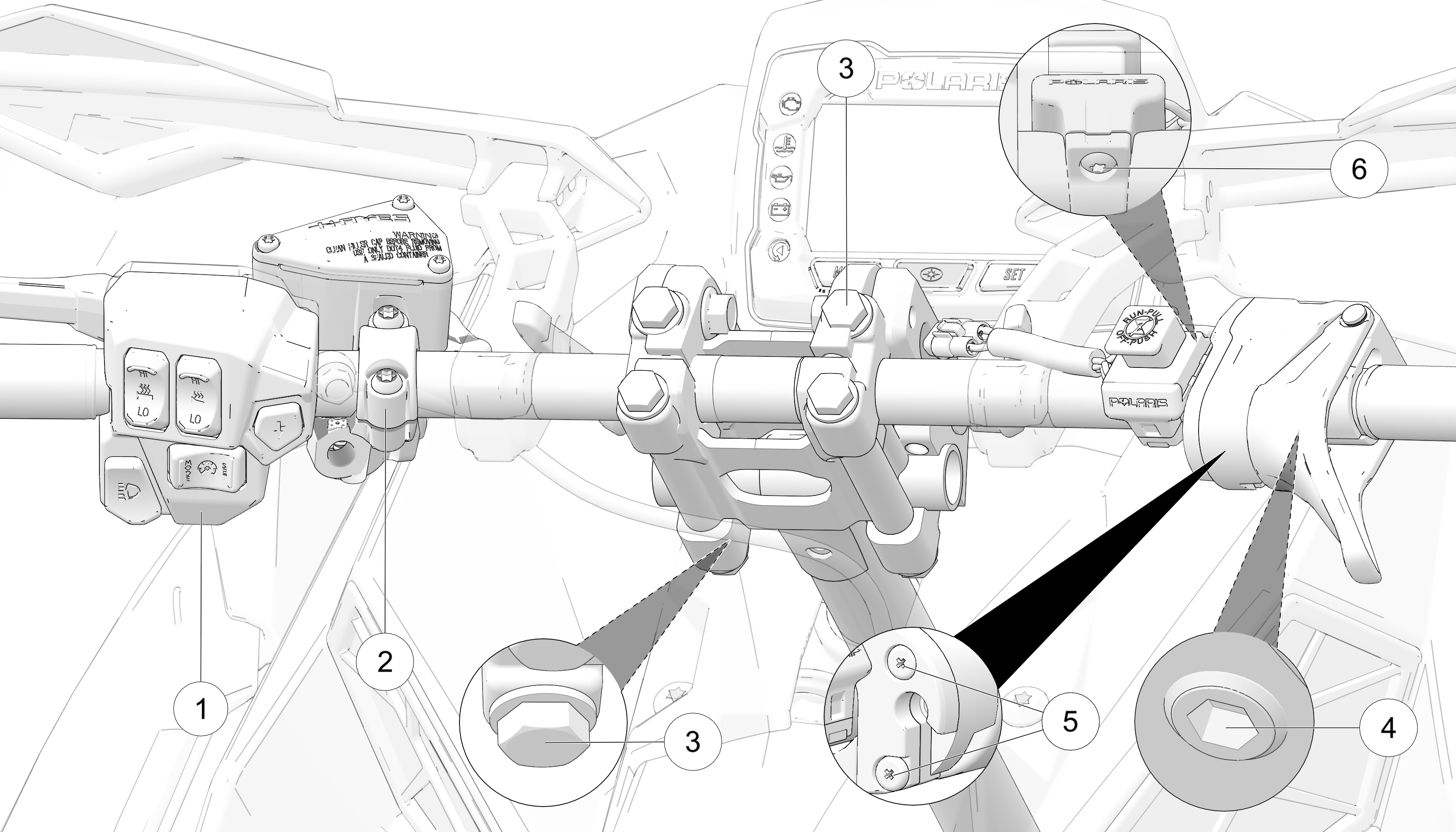

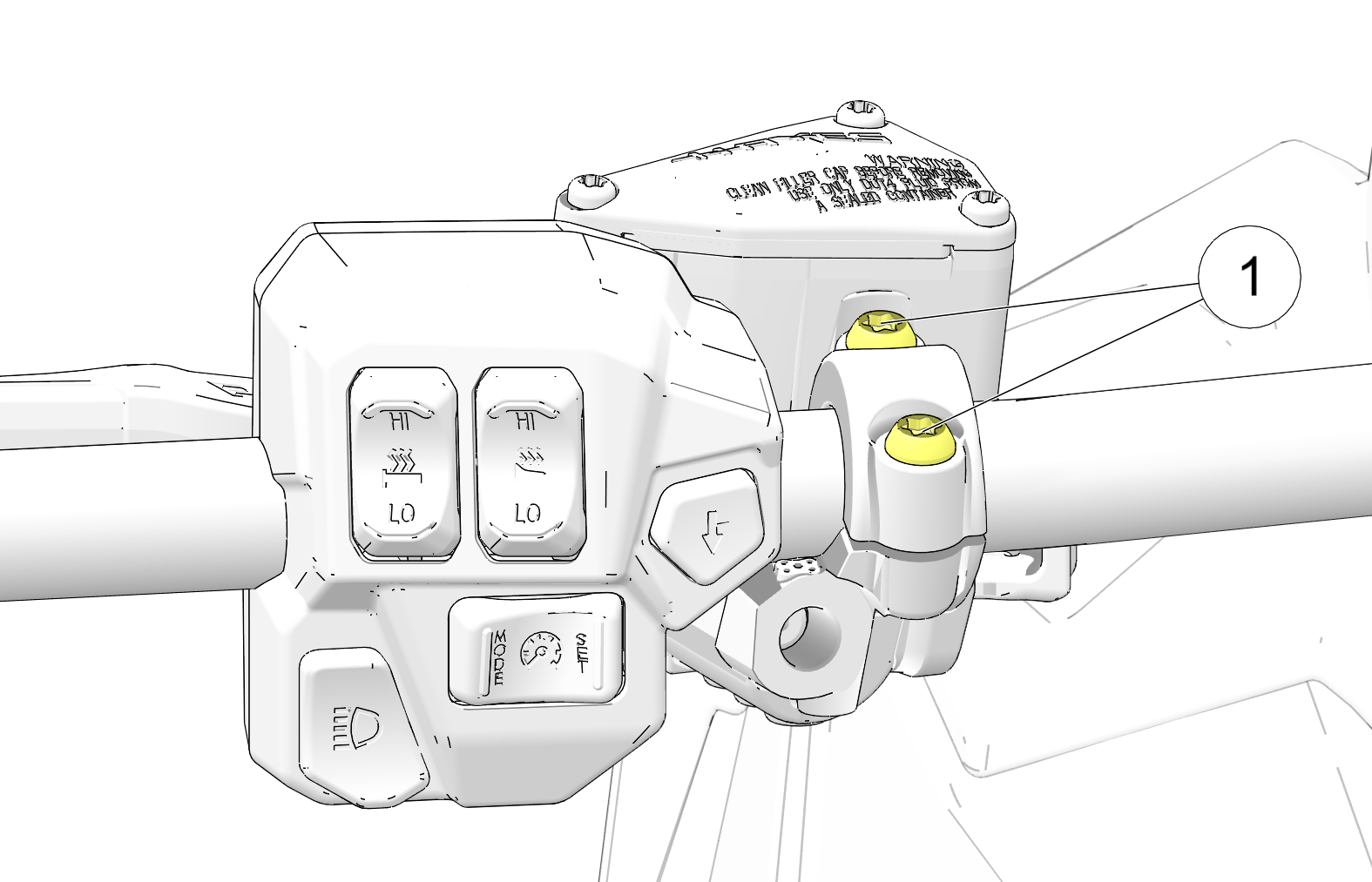

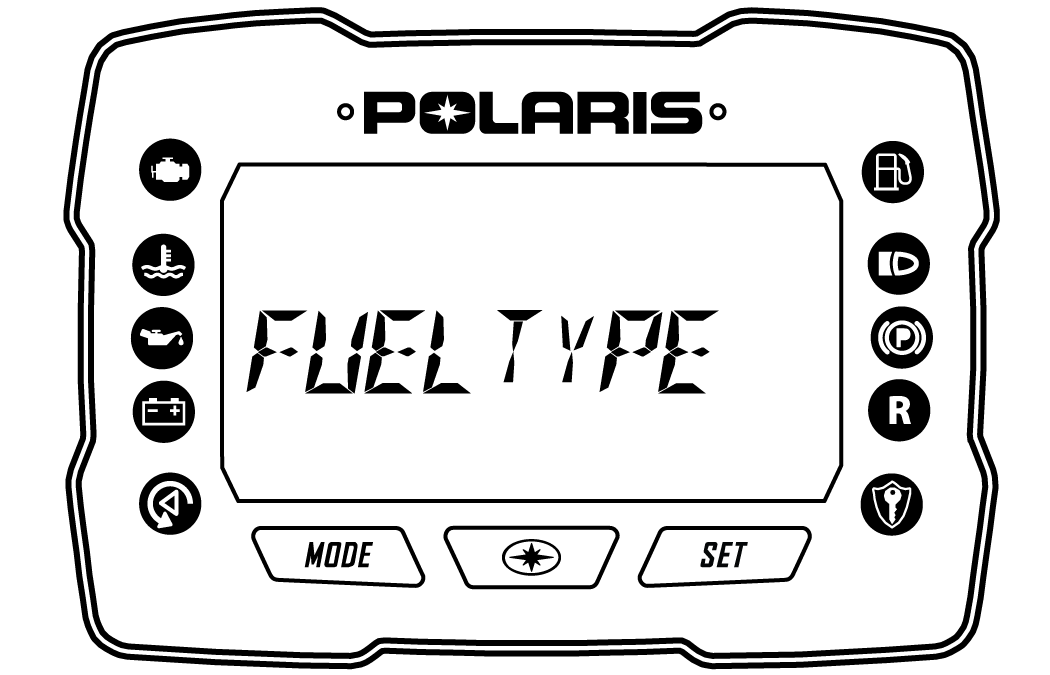

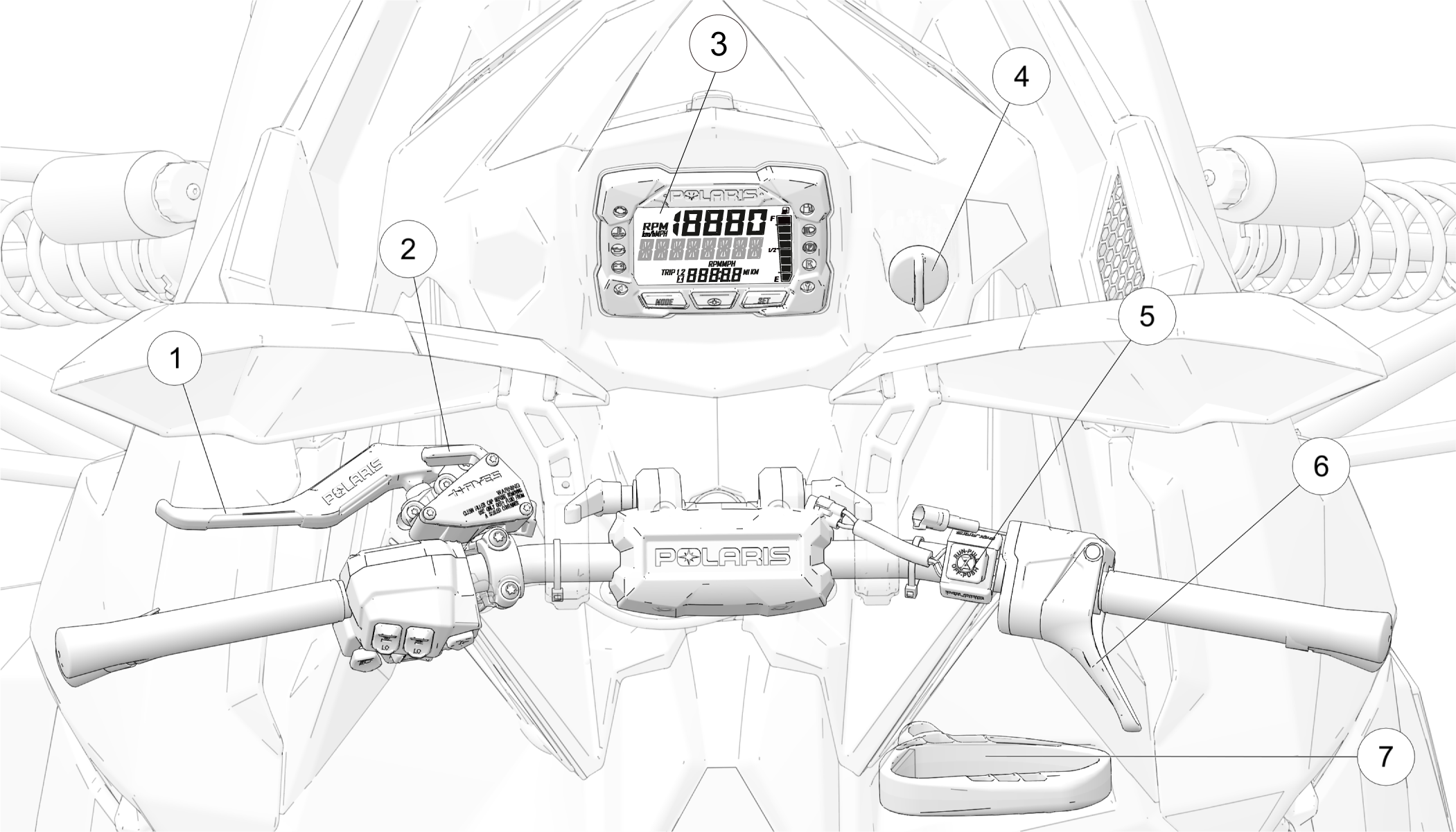

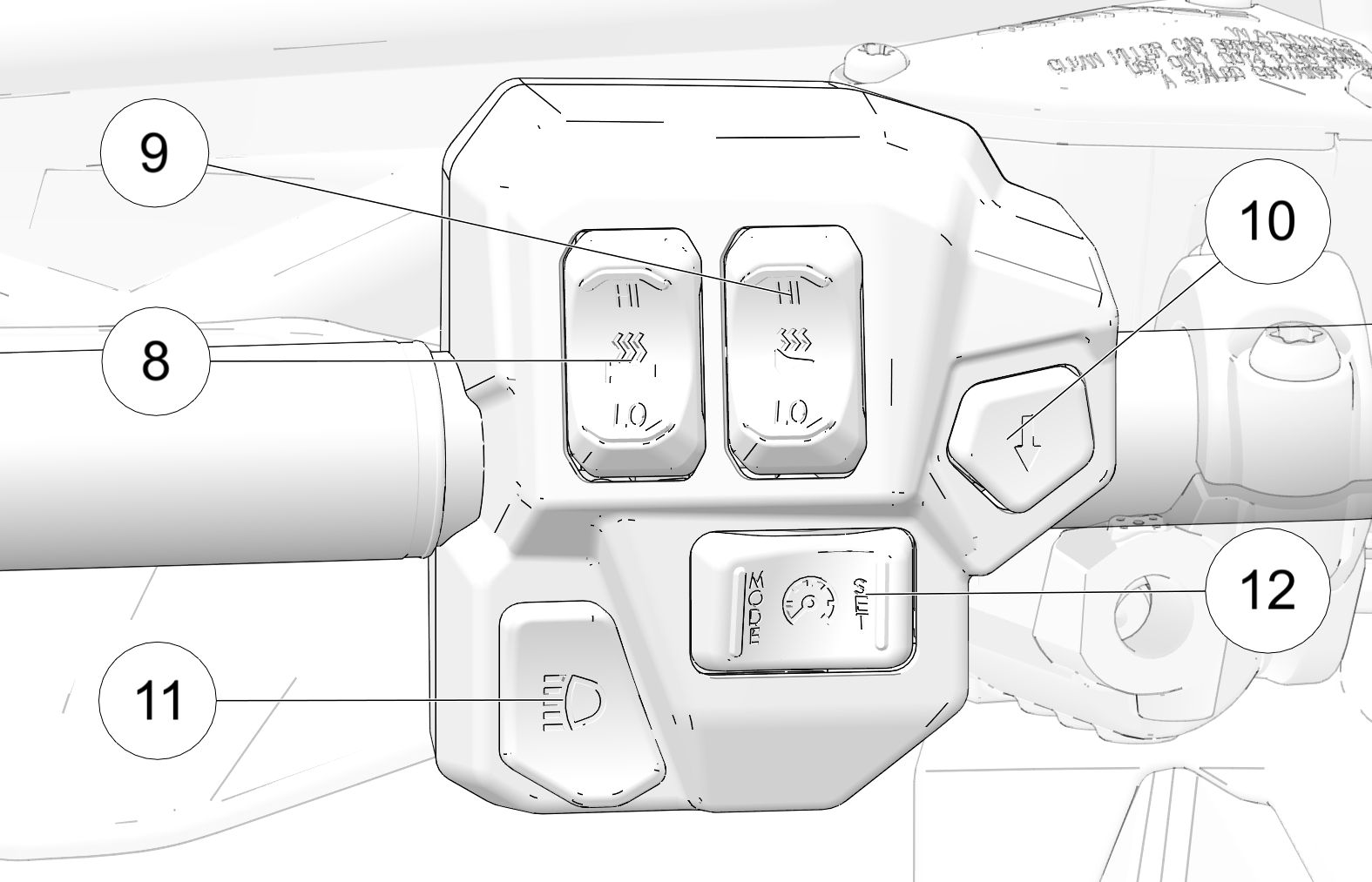

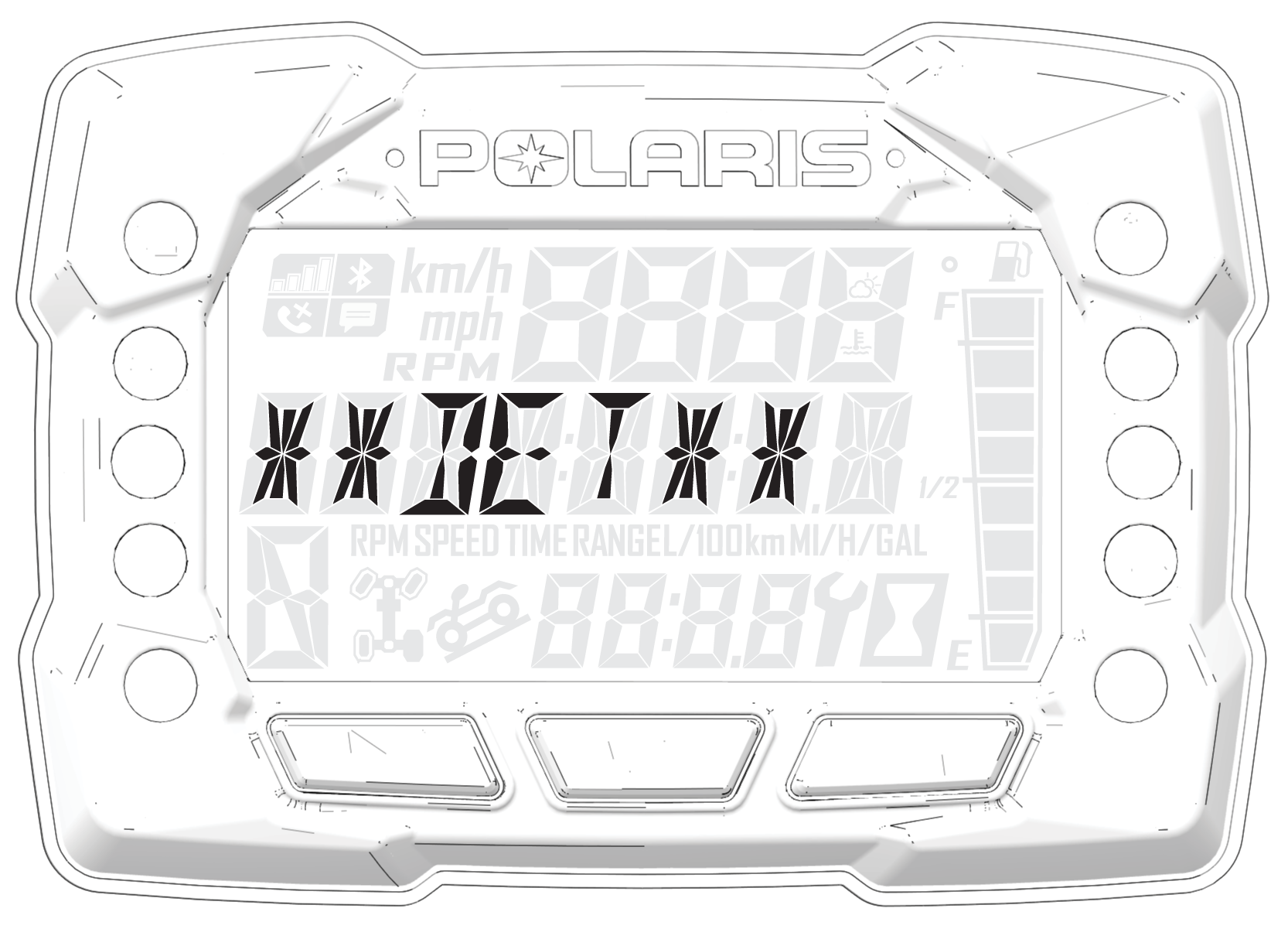

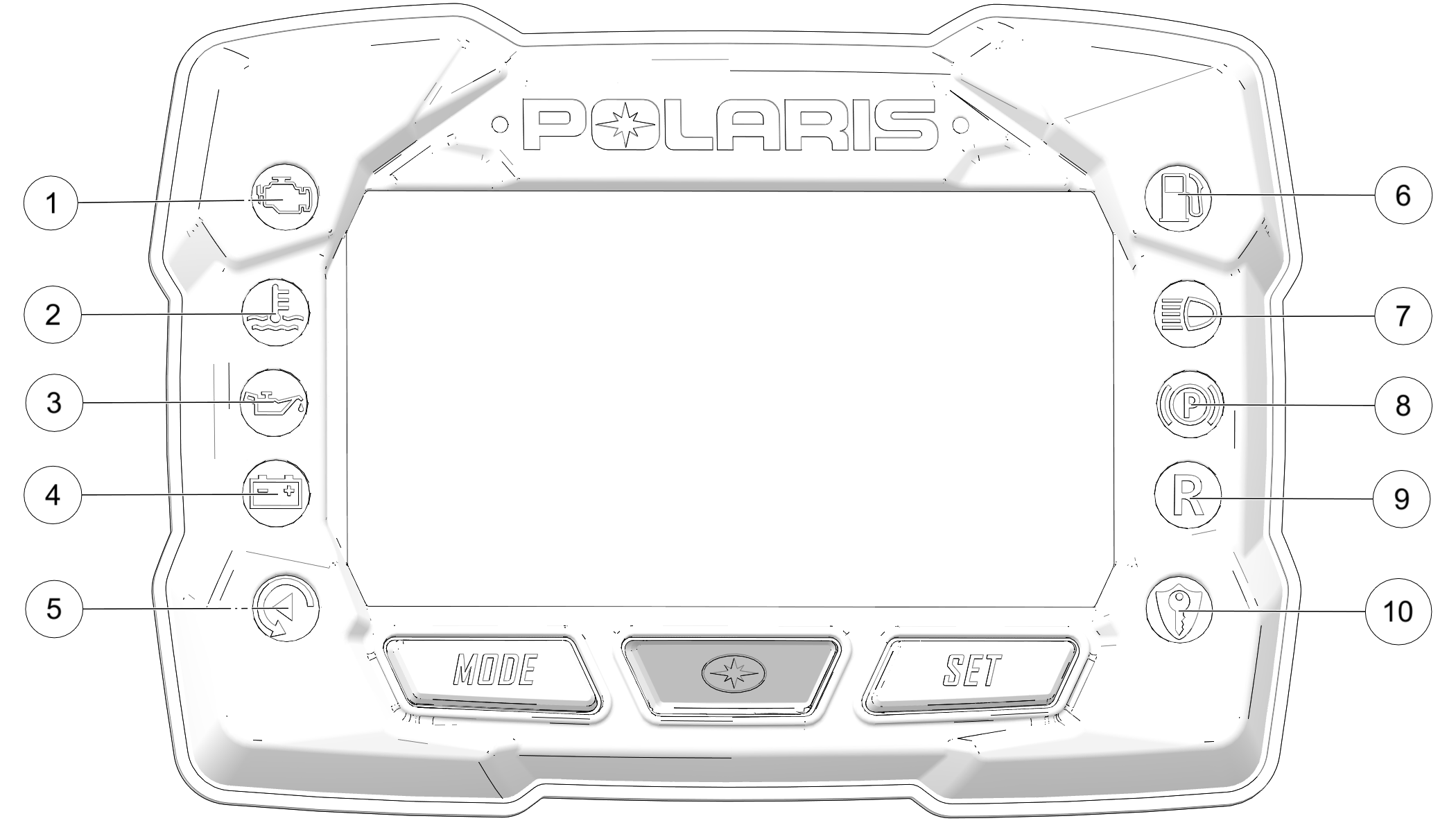

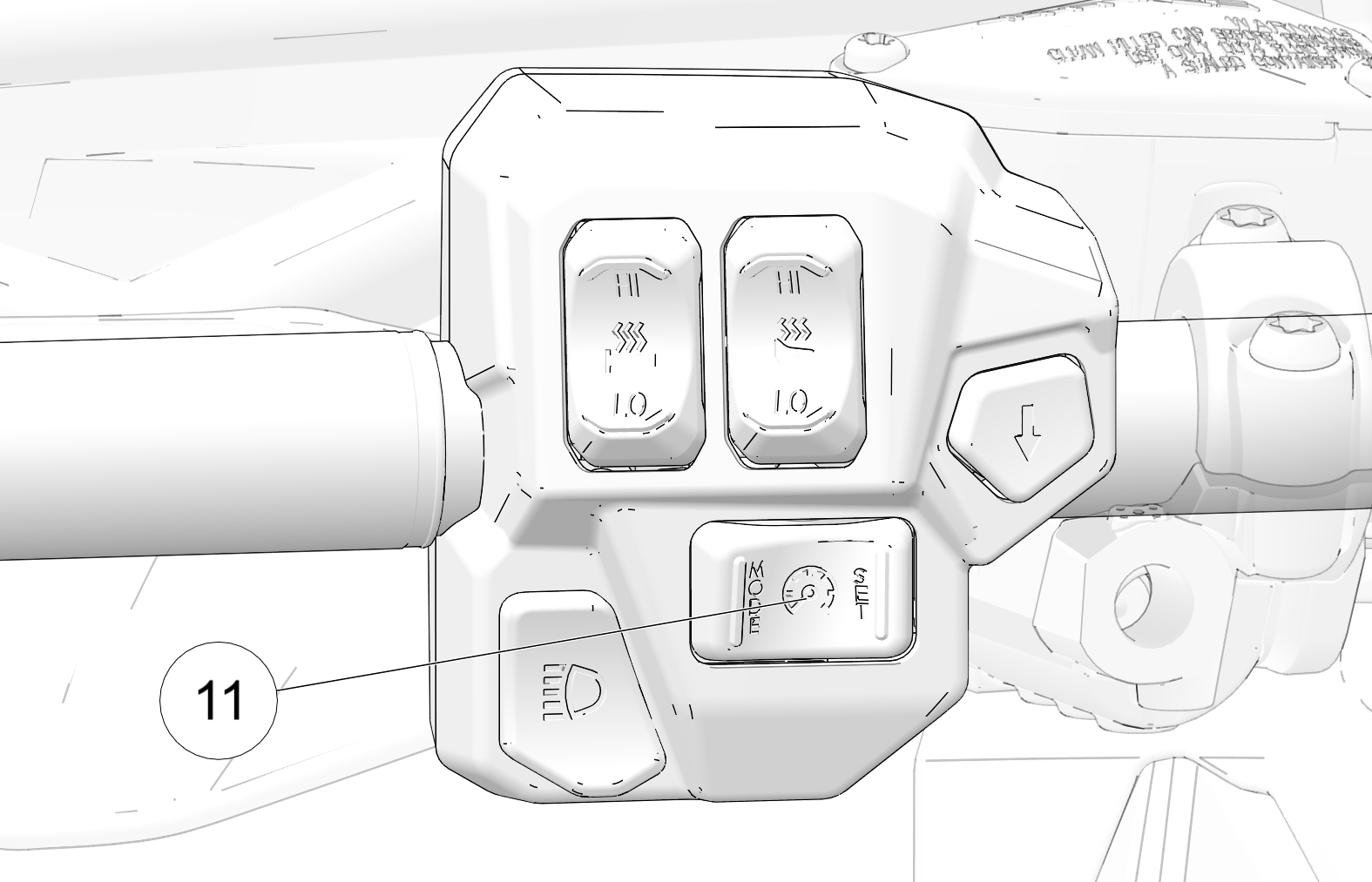

button to enter the Options

Menu.

button to enter the Options

Menu.

button on the instrument cluster to enter the Options Menu.

button on the instrument cluster to enter the Options Menu.