This POLARIS limited warranty excludes any failures that are not

caused by a defect in material or workmanship. THIS WARRANTY DOES

NOT COVER CLAIMS OF DEFECTIVE DESIGN. This warranty also does not

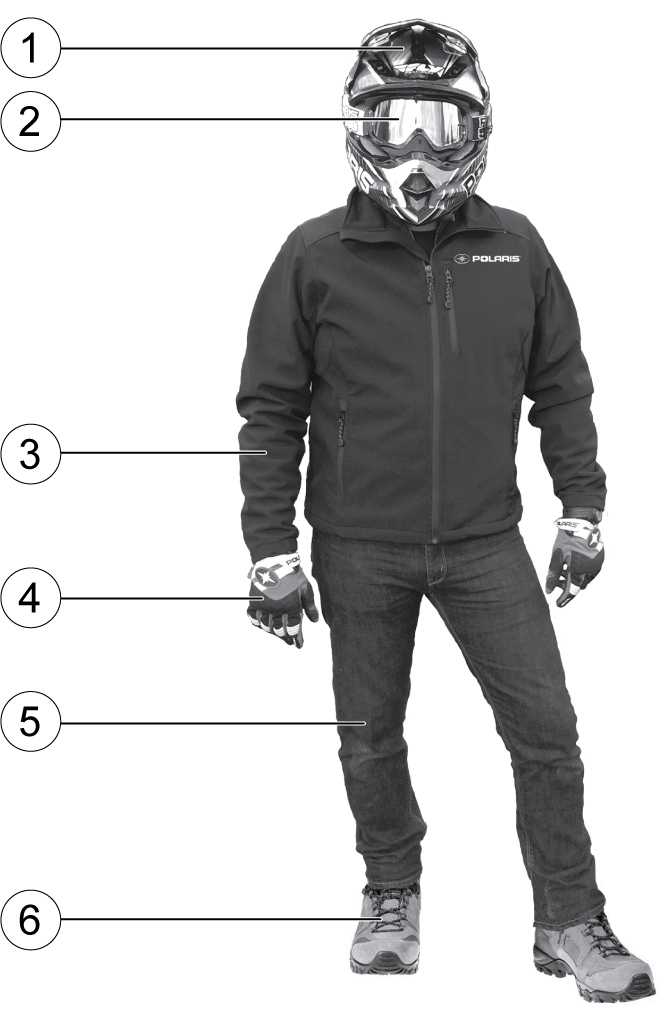

cover acts of God, accidental damage, normal wear and tear, abuse

or improper handling. This warranty also does not cover any vehicle,

component, or part that has been altered structurally, modified, neglected,

improperly maintained or used for racing, competition or purposes

other than for which it was designed.

This warranty excludes damages or failures resulting from improper

lubrication; improper engine timing; improper fuel; surface imperfections

caused by external stress, heat, cold or contamination; operator error

or abuse; improper component alignment, tension, adjustment or altitude

compensation; snow, water, dirt or other foreign substance ingestion/contamination;

improper maintenance; modified components; use of aftermarket or unapproved

components, accessories, or attachments; use of unapproved software

or calibration; unauthorized repairs; or repairs made after the warranty

period expires or by an unauthorized repair center.

This warranty excludes damages or failures caused by abuse, accident,

fire, or any other cause other than a defect in materials or workmanship

and provides no coverage for consumable components, general wear items,

or any parts exposed to friction surfaces, stresses, environmental

conditions and/or contamination for which they were not designed or

not intended, including but not limited to the following items:

-

Finished and unfinished surfaces

-

Carburetor/Throttle body components

-

Engine components

-

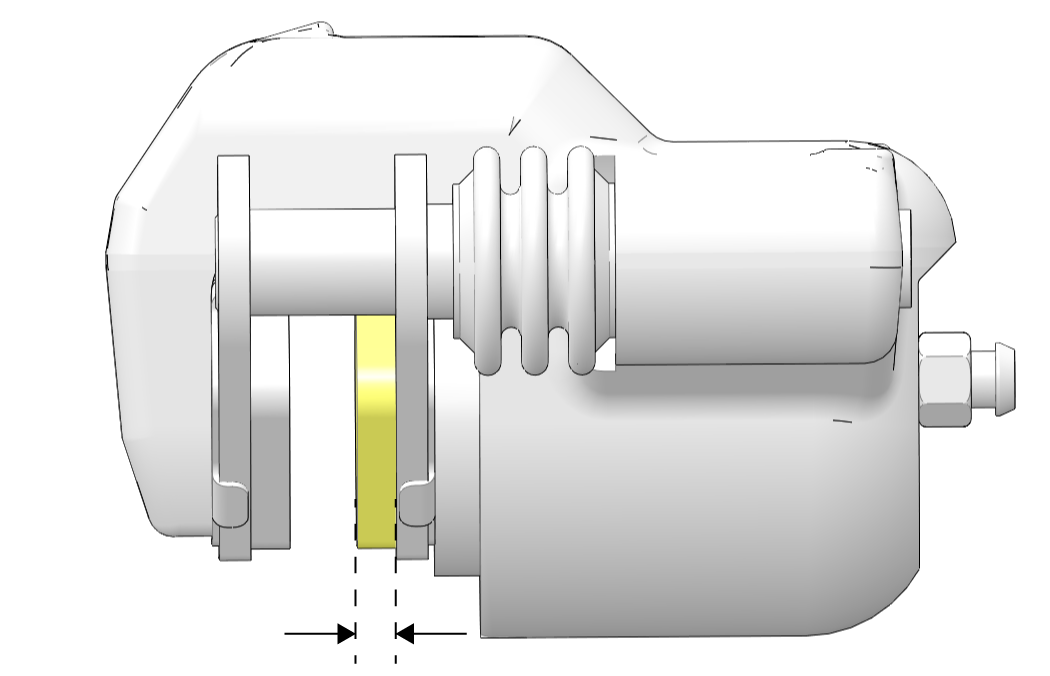

Drive belts

-

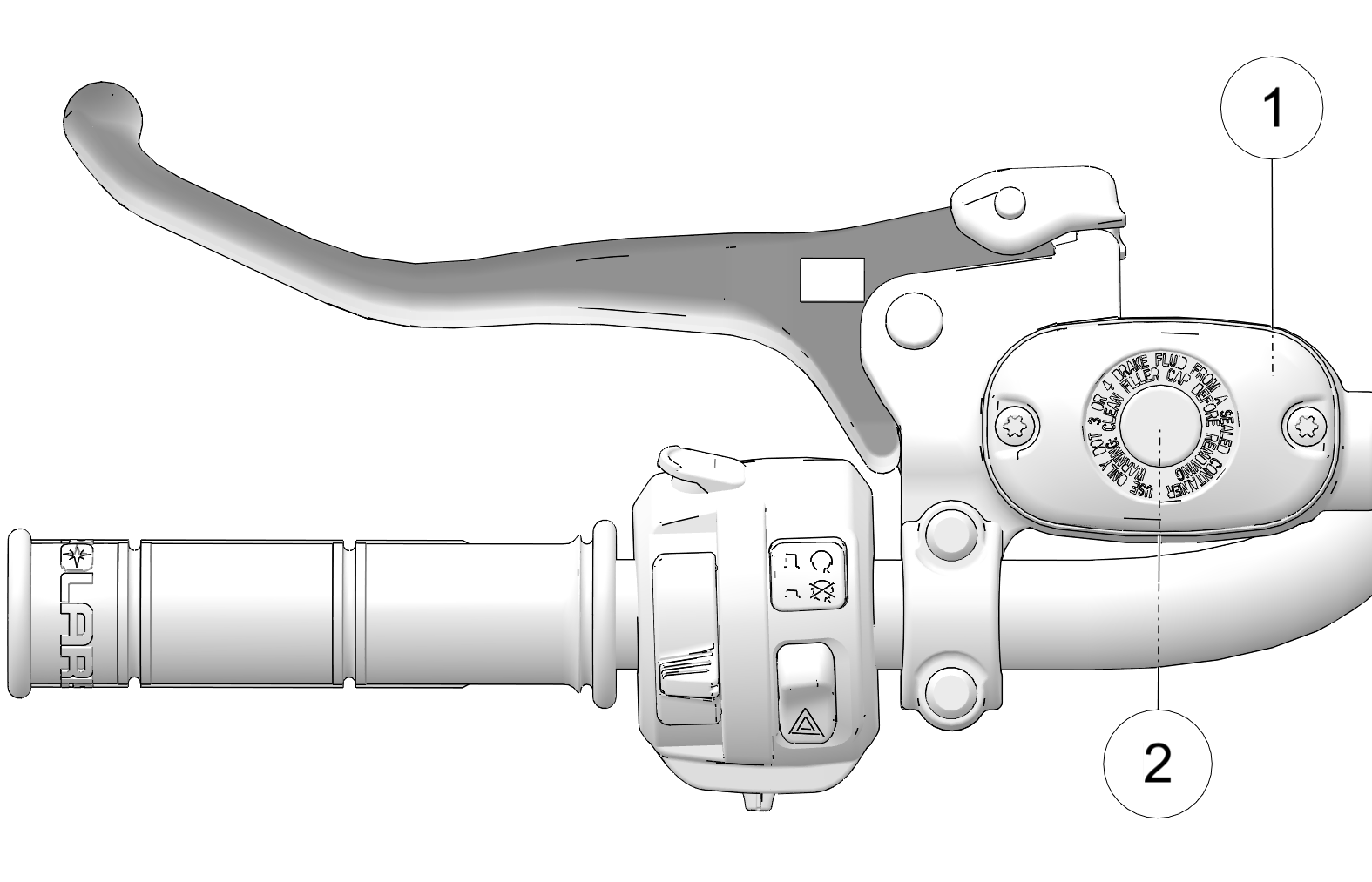

Hydraulic components and fluids

-

Circuit breakers/Fuses

-

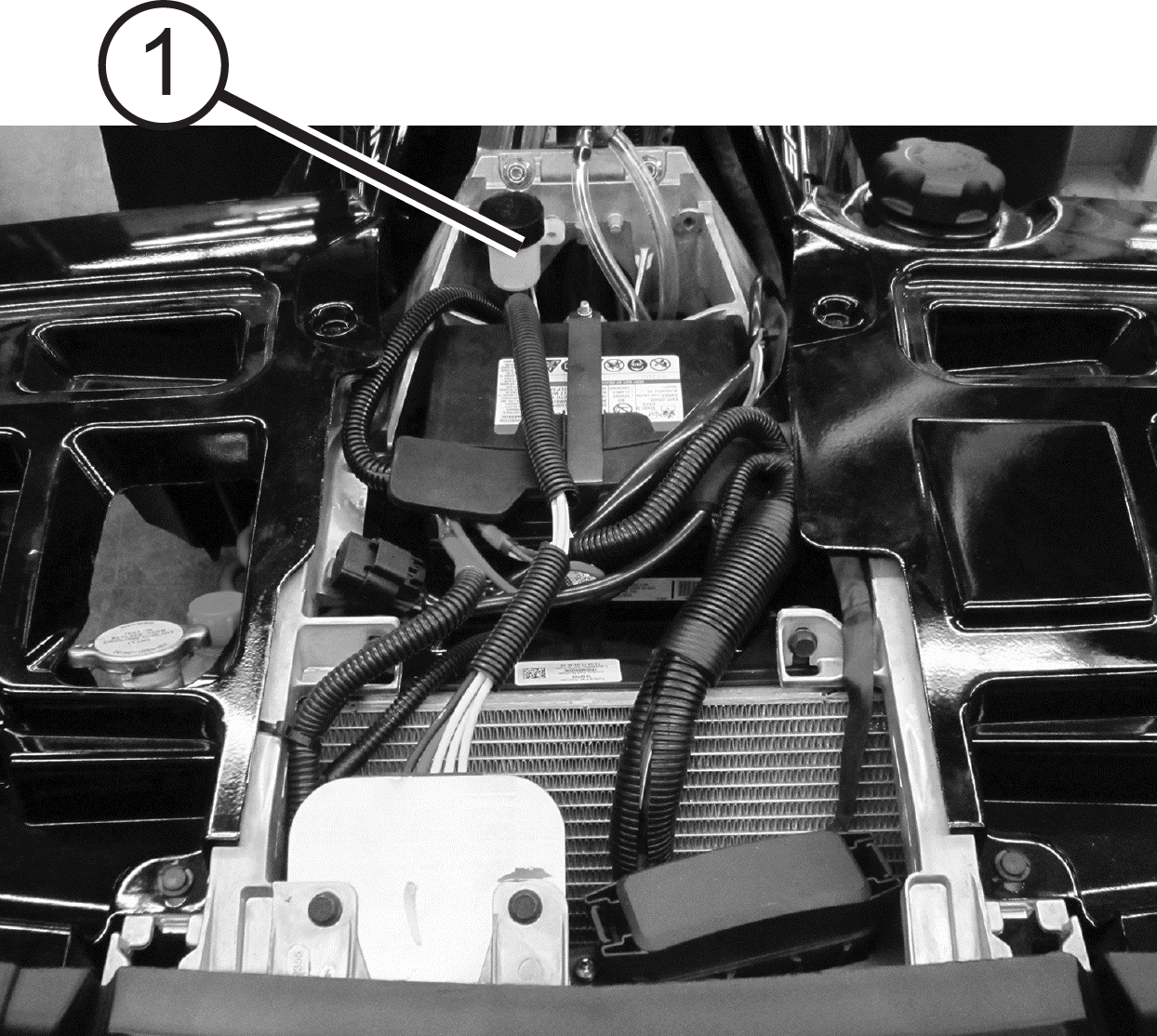

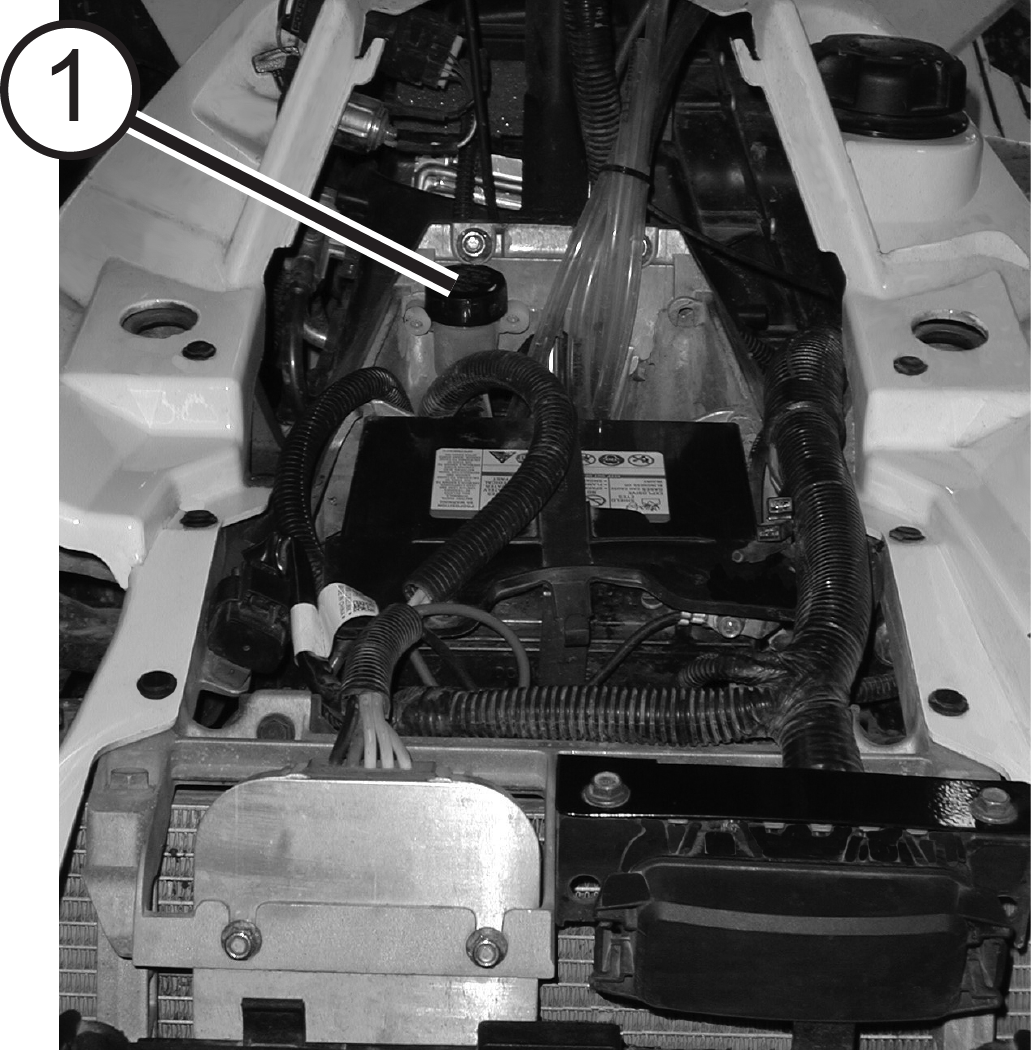

Electronic components

-

Spark plugs

-

Sealants

-

Coolants

-

Bearings