Drive responsibly. This vehicle

is not a toy and can be hazardous to operate. This vehicle has

higher ground clearance and other features to handle rugged terrain.

It can be overturned in situations where some other vehicles may not.

Abrupt maneuvers or aggressive driving, even on flat, open areas,

can cause loss of control, rollovers, severe injury or death. To avoid

loss of control and rollovers:

-

Avoid abrupt maneuvers, sideways sliding, skidding, or fishtailing,

and never do donuts.

-

Slow down before entering turn.

-

Avoid hard acceleration when turning, even from a stop.

High speed off-road operation

Driving off-road

vehicles to test the limits of your skills or abilities can be very

dangerous to you, passengers, and bystanders. Basic skills for driving

a car, ATV, or other off-road vehicles do not equip drivers to safely

attempt high speed off-road operation. Develop your skill gradually

through training, practice, and experience with the various driving

modes of this vehicle and the terrain in which you are operating.

Always do a low speed reconnaissance run (prerun) to become aware

of anything you may encounter.

High speed off-road operation can lead to loss of control, crashes,

or hard landings that can seriously injure occupants (even without

rolling the vehicle or damaging it).

If you plan on using the vehicle for high speed, off-road competition,

additional safety equipment may be necessary. Check the rules that

apply to your competition.

Do not go over jumps — going airborne can lead to serious

injury or death. Going airborne can cause loss of control, rollovers,

or crashing into the ground and may damage the vehicle. Even without

crashing, landings can be hard enough to cause any vehicle suspension

to fully compress (e.g., bottom out). Serious injuries, including

spinal injuries, can occur even if riders are properly harnessed,

wearing helmets and the vehicle is not damaged and remains upright.

You may encounter slopes, "jumps", or other terrain features that

could send the vehicle airborne, depending on your speed. These may

be defectively designed, poorly maintained, or not suitable for this

vehicle. Slow down, use extra care, and avoid going airborne. Never

take this vehicle over jumps.

Watching someone else go over a jump or go airborne does not mean

you can safely do so. Polaris cannot determine whether any jump you

may encounter is appropriate for this vehicle. Any jump, even a small

one, could be poorly maintained, designed, or not suitable for this

vehicle and may cause serious injury or death.

Plan for hills, rough terrain, ruts, and other changes in traction

and terrain. Proceed slowly and with extra care on unfamiliar

terrain. Avoid paved surfaces. Sudden changes in terrain such as holes,

depressions, banks, softer or harder ground, or other irregularities

may cause loss of control or rollover. Give yourself time to react

to rocks, bumps, or holes that may be hard to see. Operating in deep

snow or tall grass may make it harder to see obstacles.

If you cannot go around an obstacle, such as a fallen tree or a

ditch, stop the vehicle in a safe place. Get out to inspect the area

thoroughly. Look from both your approach side and exit side. If you

are reasonably confident you can continue safely, choose the path

that will allow you to go straight over the obstacle to minimize the

vehicle tipping sideways. Go only fast enough to maintain your momentum,

but still give yourself plenty of time to react to changes in conditions.

If there is any question about your ability to maneuver safely over

the obstacle, you should turn around if the ground is flat and you

have the room, or back up until you find a less difficult path.

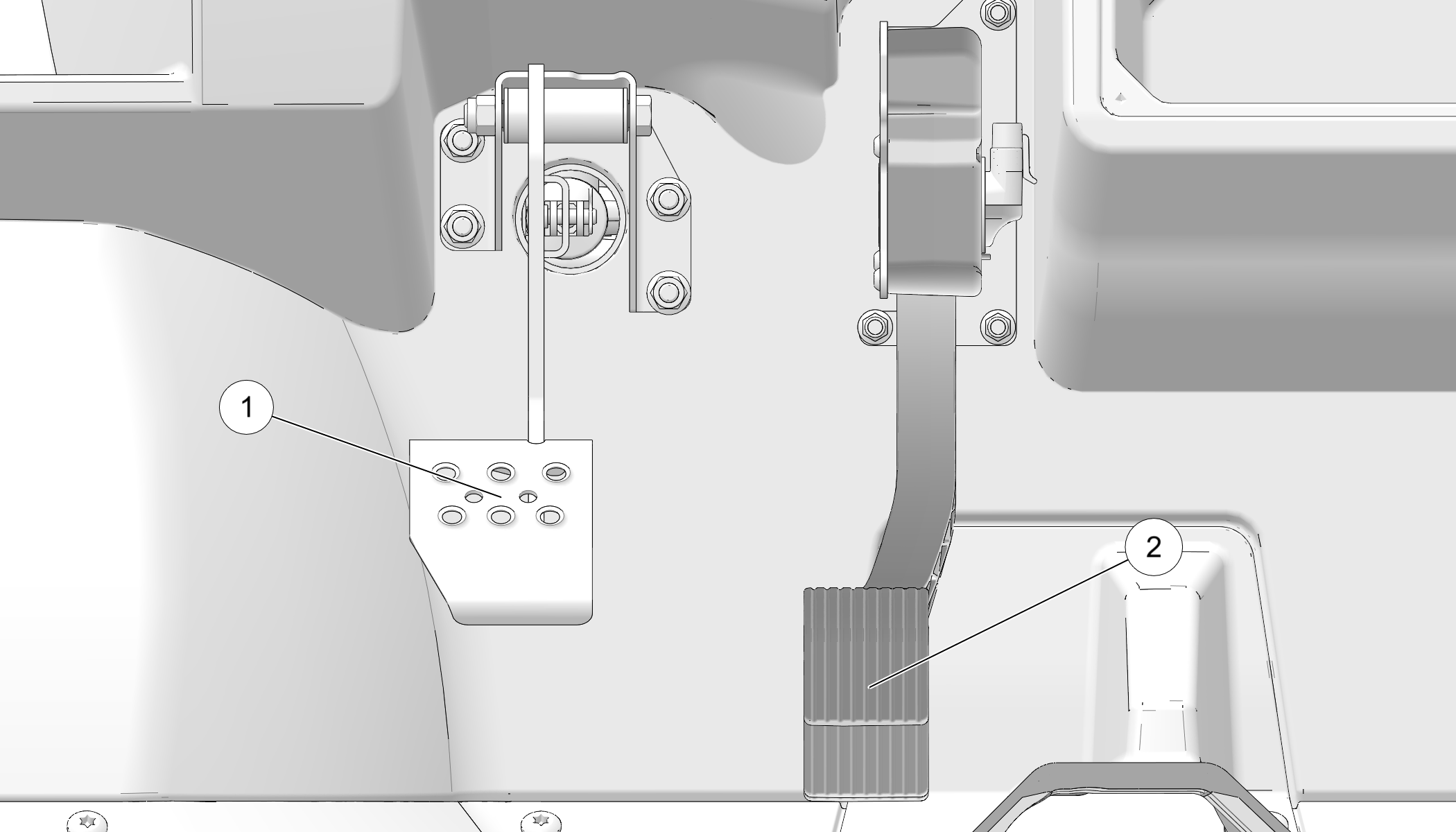

Abrupt application of the accelerator pedal can cause the tires

to lose traction, reducing control of the vehicle and increasing the

possibility of an accident, especially while on sloped terrain or

while crossing obstacles such as rocks or logs.

MD MODELS ONLY

Avoid Operating on Public Roads

(Paved or Otherwise). This vehicle does not have highway safety

features that on-road vehicles may have (air bags, anti-lock brakes,

stability control, etc.). If another vehicle collides with you, the

likelihood of a serious injury or death may be greater. Also, you

may not be able to avoid a crash or rollover if you make sudden or

abrupt maneuvers such as swerving or emergency braking. While it may

be legal locally to drive on some public roads in specific parts of

the country, your vehicle was not designed or certified as an on-road

motor vehicle. Polaris does not support public road use except as

may be necessary to cross-roads designated for connecting off highway

vehicle trail segments. If you must drive on-road, drive slowly and

defensively. Your vehicle may lack the features needed to comply with

state or local laws that permit limited public road use. Modifications

you make to your vehicle to meet these requirements may void the vehicle

warranty. In addition, refer to tire manufacturer’s instructions

or limitations for on-road operation, including speed limits and premature

tire wear.

ZUGMASCHINE OR TRACTOR MODELS ONLY

This vehicle

is approved for on-road use.

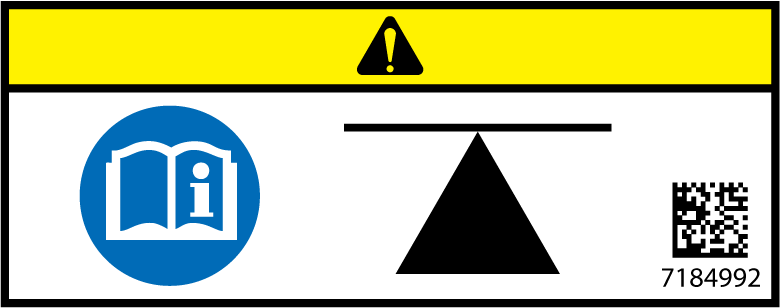

Improperly operating on hills can cause loss of control, rollover,

or accident, which can lead to serious injury or death. Use extra

care when operating on hills. Plan for rough terrain, ruts, and other

changes in traction and terrain.

Driving up hills

Check the terrain before

ascending a hill and make sure it is not too slippery or loose. Engage

all-wheel drive for hills. Drive straight uphill, keeping speed and

throttle steady. Avoid steep hills which can cause the vehicle to

overturn.

Recovering from stalling on a hill

If the

vehicle loses forward speed, apply the brakes gradually and stop.

Do not attempt to turn the vehicle around. Instead, shift to reverse

and allow the vehicle to slowly roll straight downhill. Apply light

brake pressure to control speed.

Overtopping a hill

Slow down when you reach

the crest of a hill. Never blindly go over the crest of a hill or

a drop off at high speed. An obstacle, a sharp drop, or another vehicle

or person could be on the other side of the hill.

Driving down hills

Check the terrain before

descending a hill and make sure it is not too slippery or loose. Engage

all-wheel drive and proceed slowly, applying the brakes lightly. Never

descend a hill with the transmission in neutral or if the engine is

turned off.

Avoid side hilling (riding across slopes)

If unavoidable, proceed slowly and with extra caution. Avoid obstacles

and changes in terrain that could cause the vehicle to tip or slide.

If it feels like the vehicle begins to tip or slide, immediately turn

downhill.

Riding near wooded areas or brush

Use extra

caution when operating near trees, particularly when operating on

narrow trails. Tree branches or brush can be driven into the cab striking

or stabbing occupants.

Riding in snow

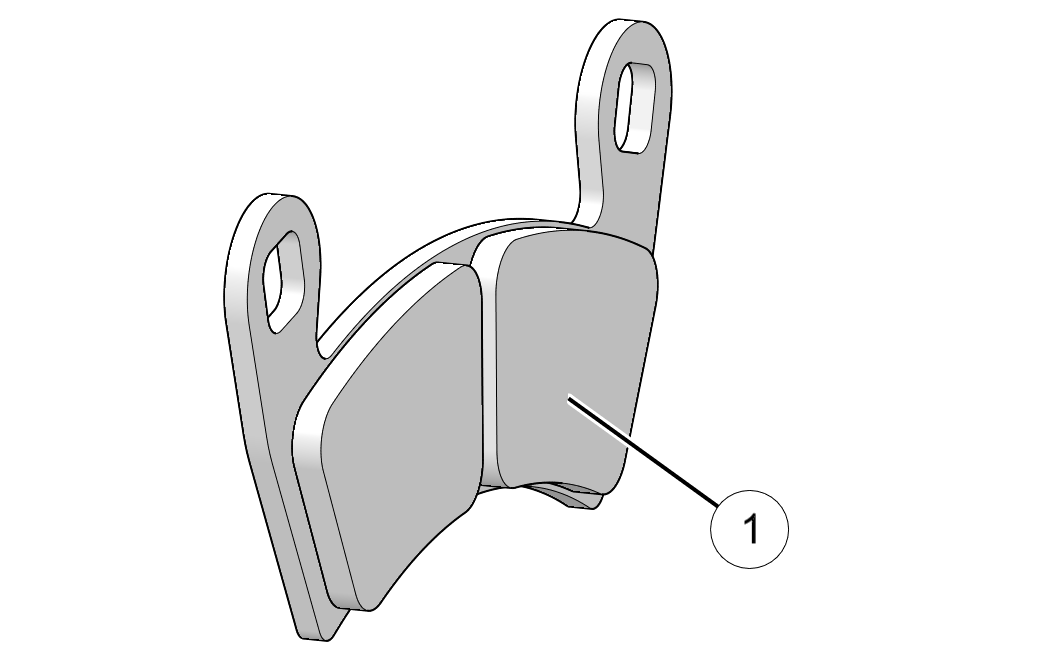

Always keep the brake and

accelerator pedals free of snow and ice. Apply the brakes frequently

to prevent ice or snow accumulation on the brake pads which can reduce

brake performance.

Riding on ice

Never operate the vehicle on

a frozen body of water unless you have verified that the ice can support

the weight of the vehicle. Severe injury or death can result if the

vehicle falls through the ice.

Riding in water / Falling into water

Operating

through deep or fast-flowing water can cause loss of traction, loss

of control, overturning, or being swept away in water. You can be

seriously injured or killed from entrapment and drowning. Never operate

the vehicle in fast-flowing water or in water that exceeds the floor

level of the vehicle. Avoid sharp drop-offs and large rocks. Choose

a path that provides an entrance and exit point with gradual inclines.

Wet brakes may have reduced stopping ability. After leaving water,

test the brakes. Apply them lightly several times while driving slowly.

The friction will help dry out the pads.

Riding on sand dunes

Use extra caution when

operating on or near dunes. Be alert for changes in terrain. Never

blindly go over the crest of a hill or a drop-off at high speed. An

obstacle, a sharp drop, or another vehicle or a person could be on

the other side of the hill.

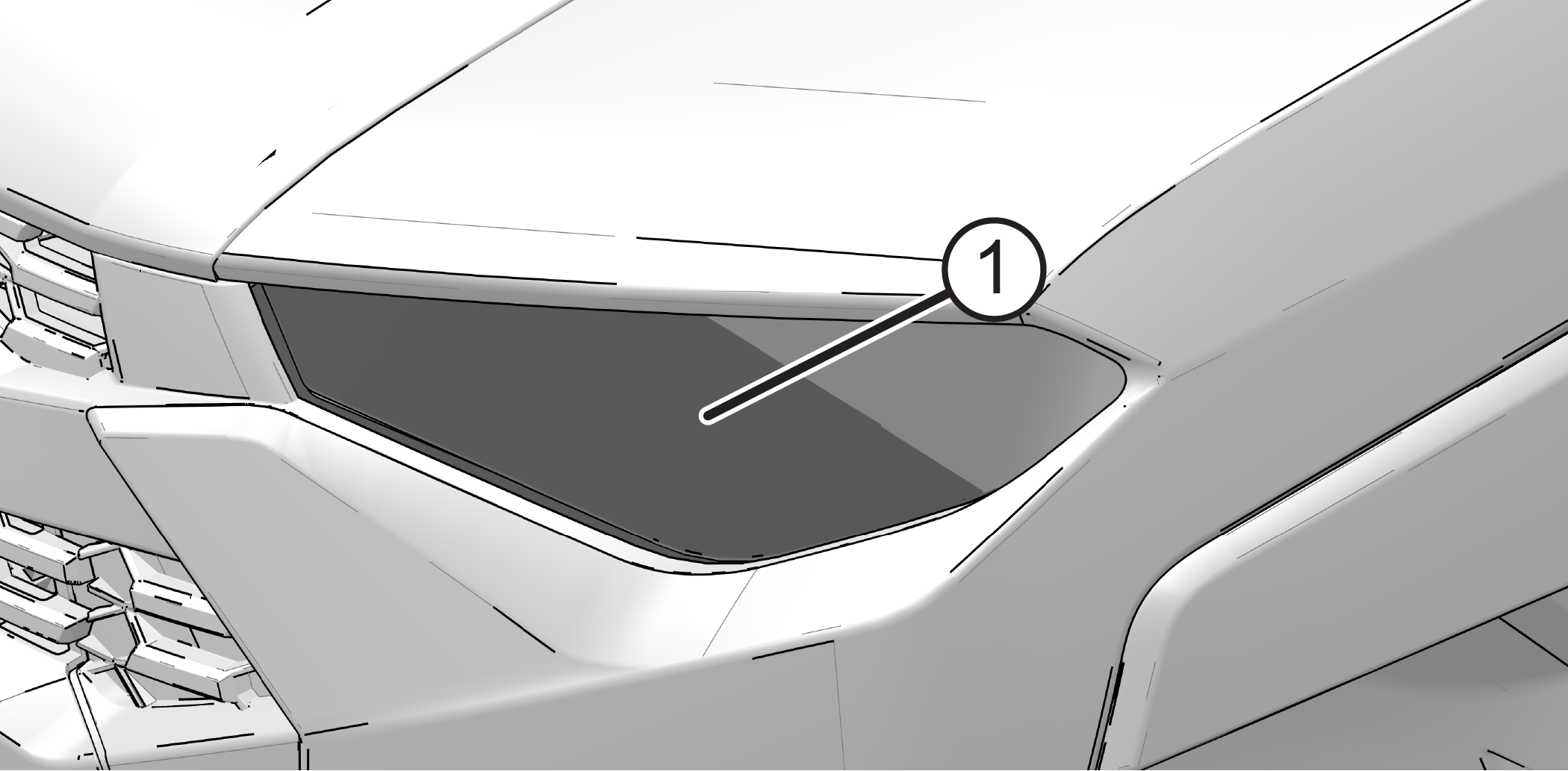

Riding in low-visibility conditions

Use extra

caution and drive slowly in conditions of reduced visibility such

as fog, rain, and darkness.

Plan ahead to avoid the need for evasive maneuvers, such as

swerving. Hitting an obstacle — including wildlife —

you are not ready for can be dangerous. Choosing to swerve instead

can be even more dangerous because it can lead to loss of control,

rollover, or collisions.

When operating in areas with possibility of wildlife appearing

in your path, plan ahead to avoid swerving for animals if doing so

could result in collisions or rollovers. Go slowly or avoid driving

during seasons or times of day when animals such as deer are more

likely to cross your path without warning.

Avoid Collisions With Other Vehicles

When

following another vehicle or operating in the same area as others,

keep a safe distance to avoid collisions. Allow extra space when sight

distances are limited by dust, snow, curves, hills, or other conditions.

Plan ahead to avoid having to swerve or leave the trail to avoid a

collision.

On trails, be prepared to make space for other vehicles to pass.

If you need to stop on a trail, move your vehicle to the edge of the

path to allow others to pass safely.

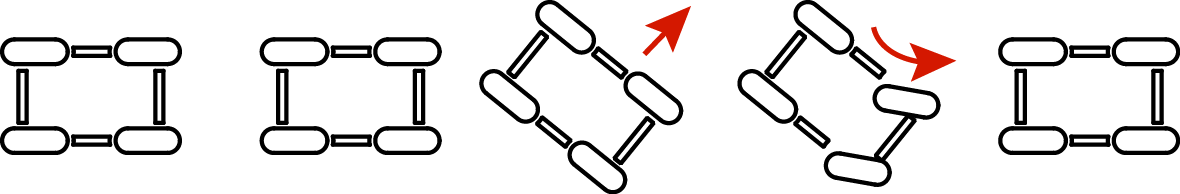

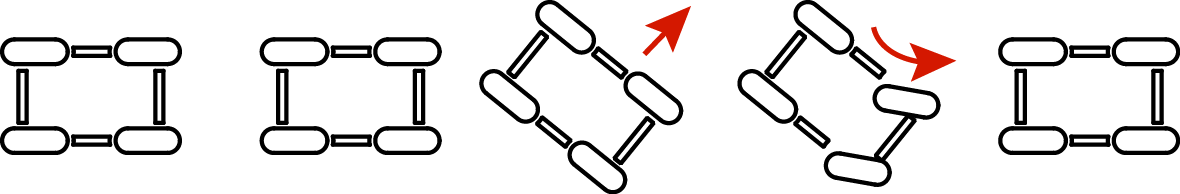

Correct a skid by turning the steering wheel in the direction

of the skid.

Never apply the brakes during a skid.

If the vehicle begins to slide downhill or you feel it may tip,

turn downhill immediately and stop. Maneuver slowly and carefully

until you can drive straight downhill.

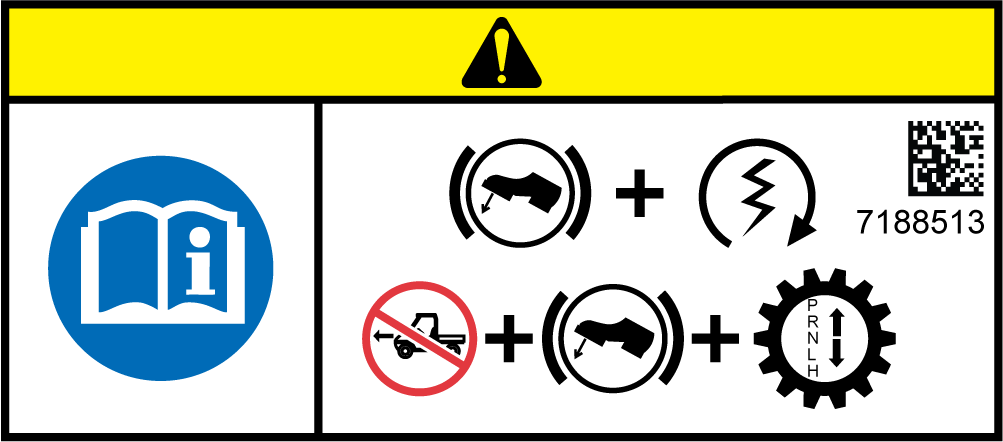

Do not continue driving if your vehicle may be damaged or if

you were in a crash or rollover.

Operating the

vehicle while damaged or after a crash or rollover can cause loss

of control, rollover, or accident, which can lead to serious injury

or death. If you cannot safely transport the vehicle on your own,

contact a recovery and towing service.

After any crash, rollover, or other accident, have a POLARIS dealer

inspect the vehicle for possible damage, including seat belts, ROPS,

brakes, suspension, and steering systems.

Be prepared in case your vehicle becomes damaged or disabled, especially

in remote areas. Consider in advance how to get help and stay safe

until it arrives whenever you ride.

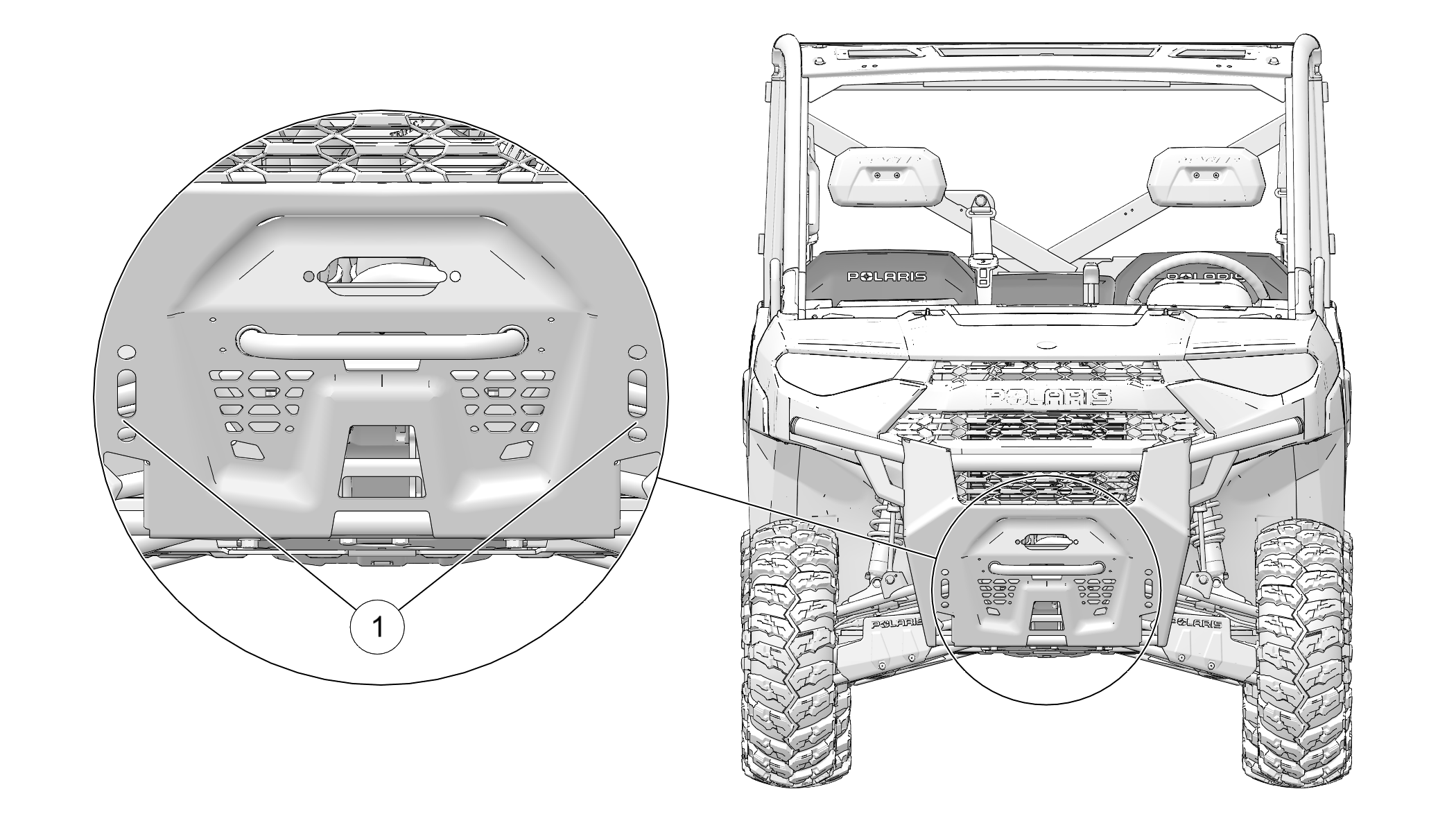

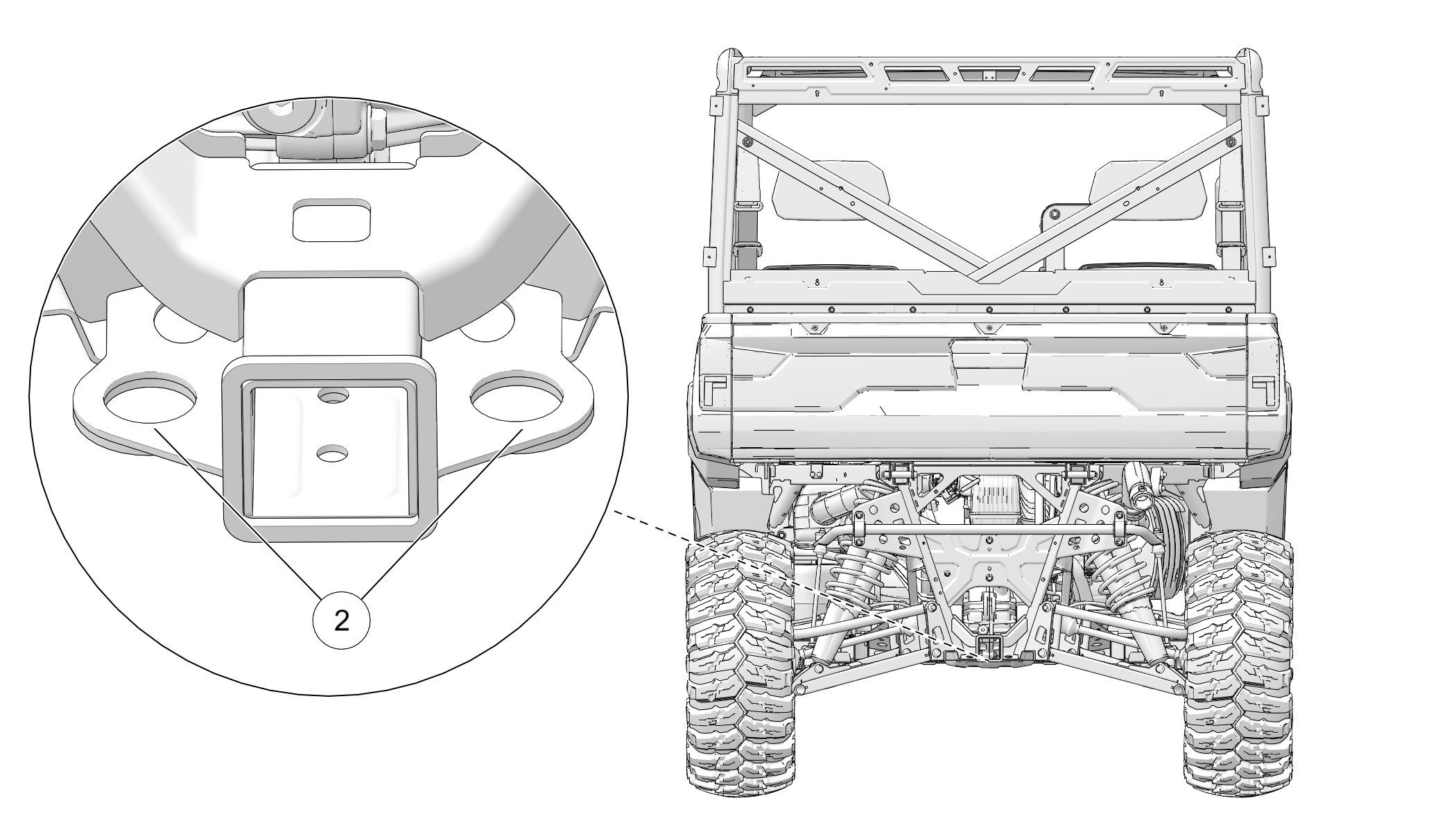

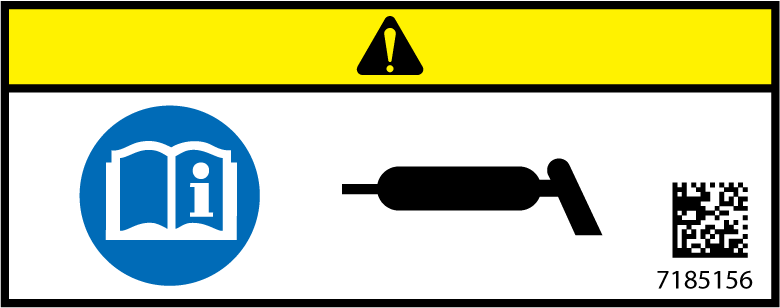

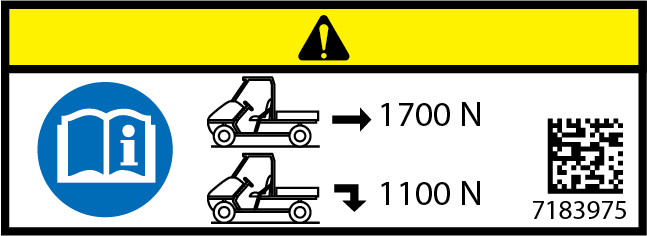

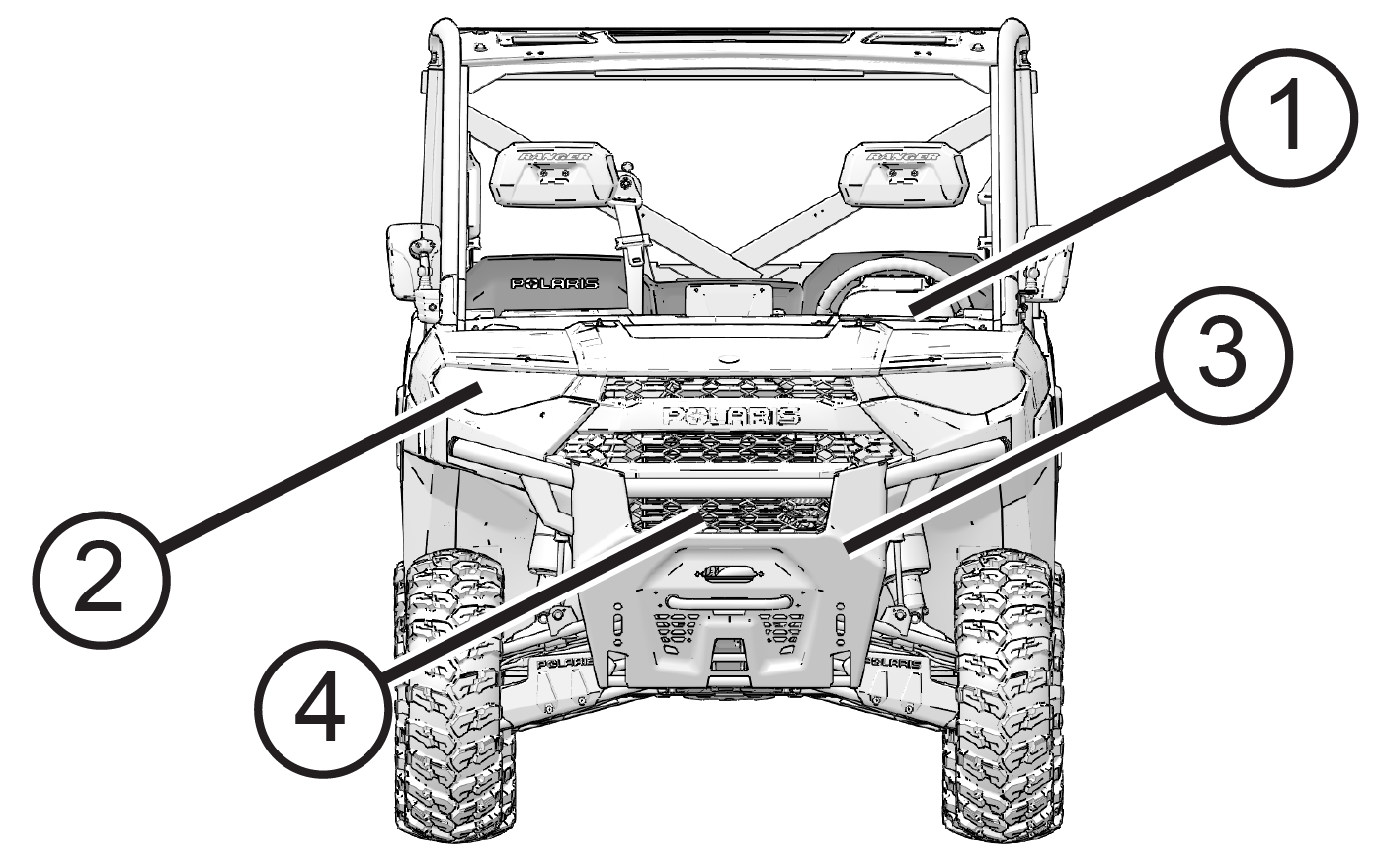

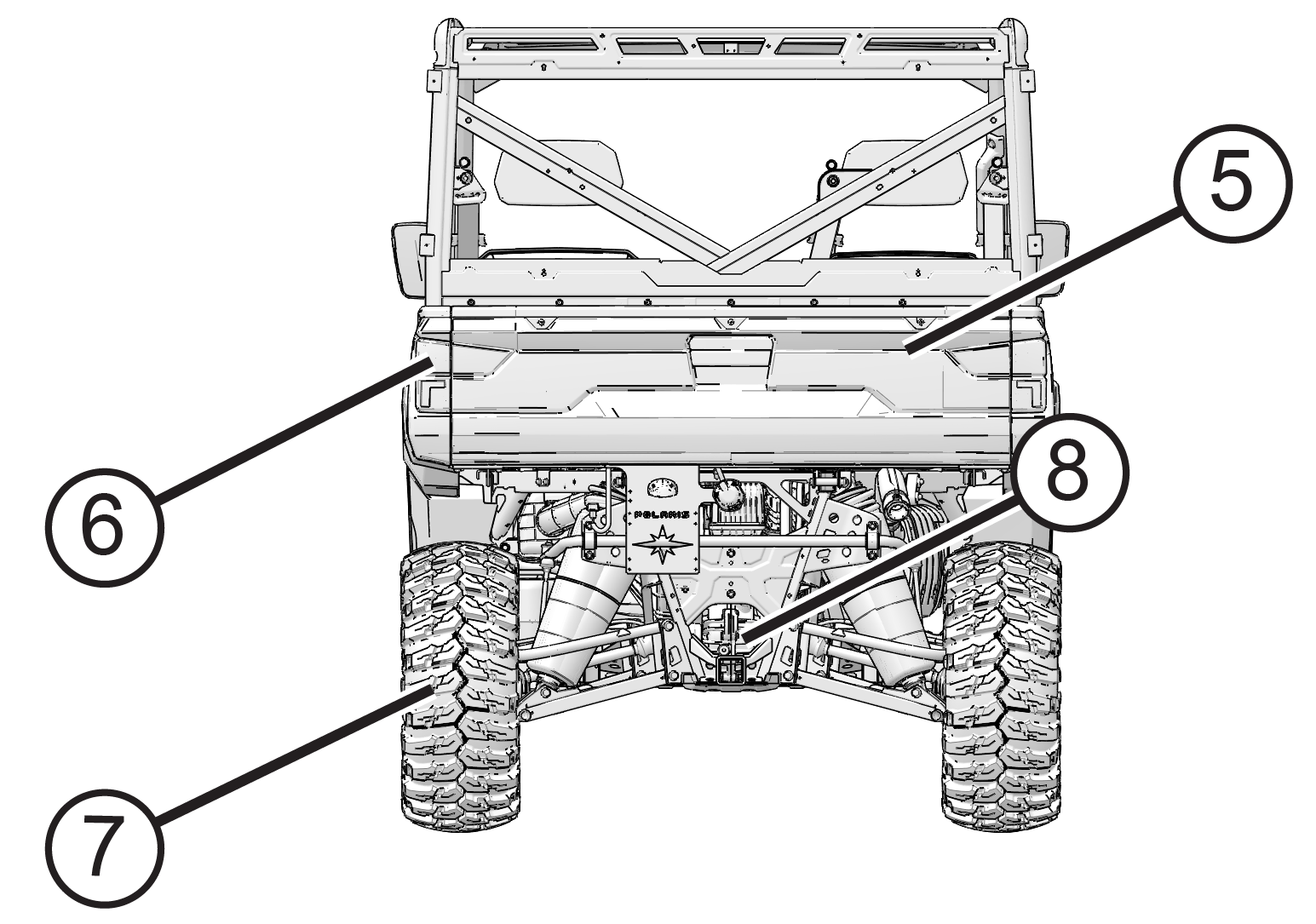

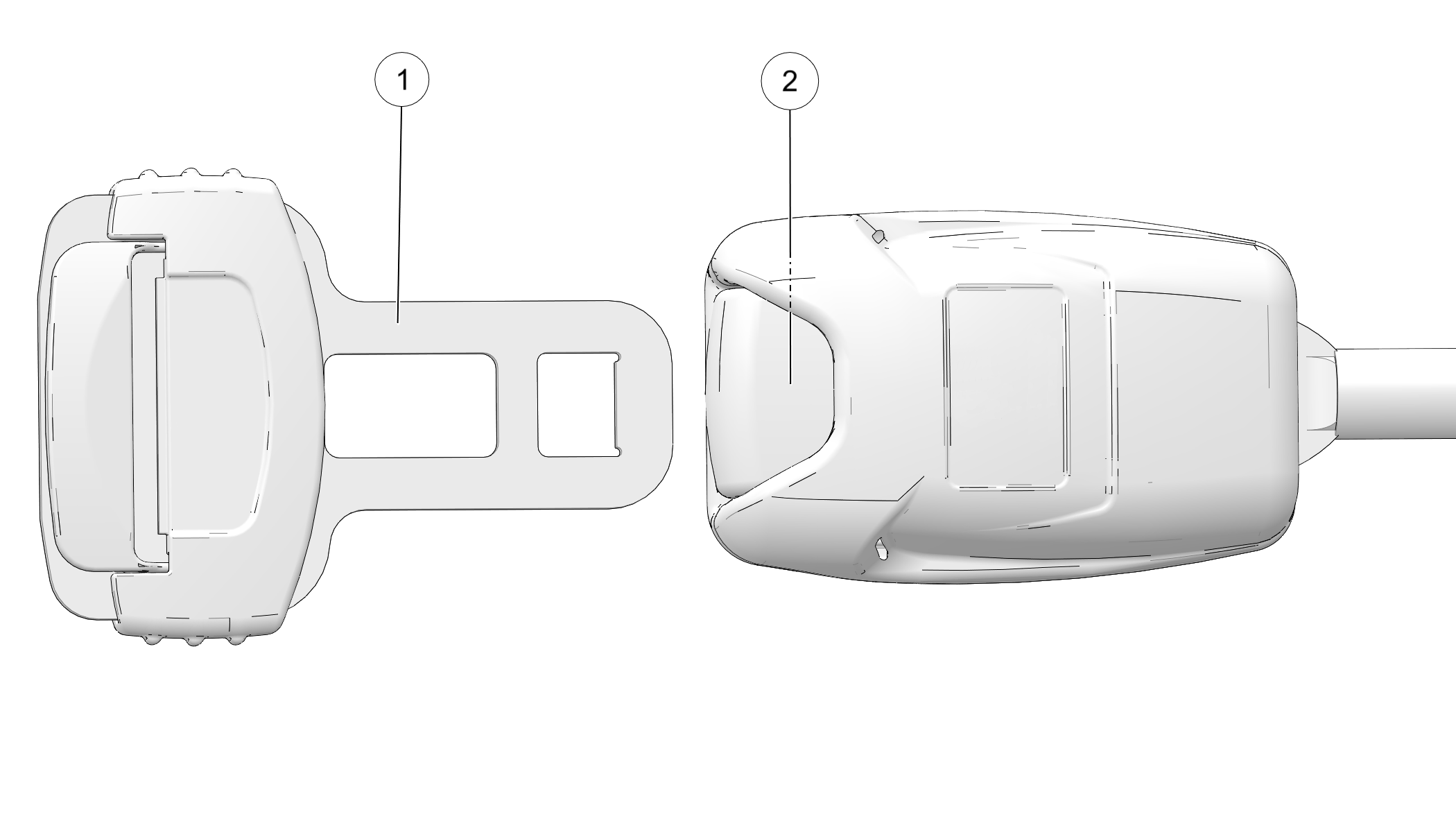

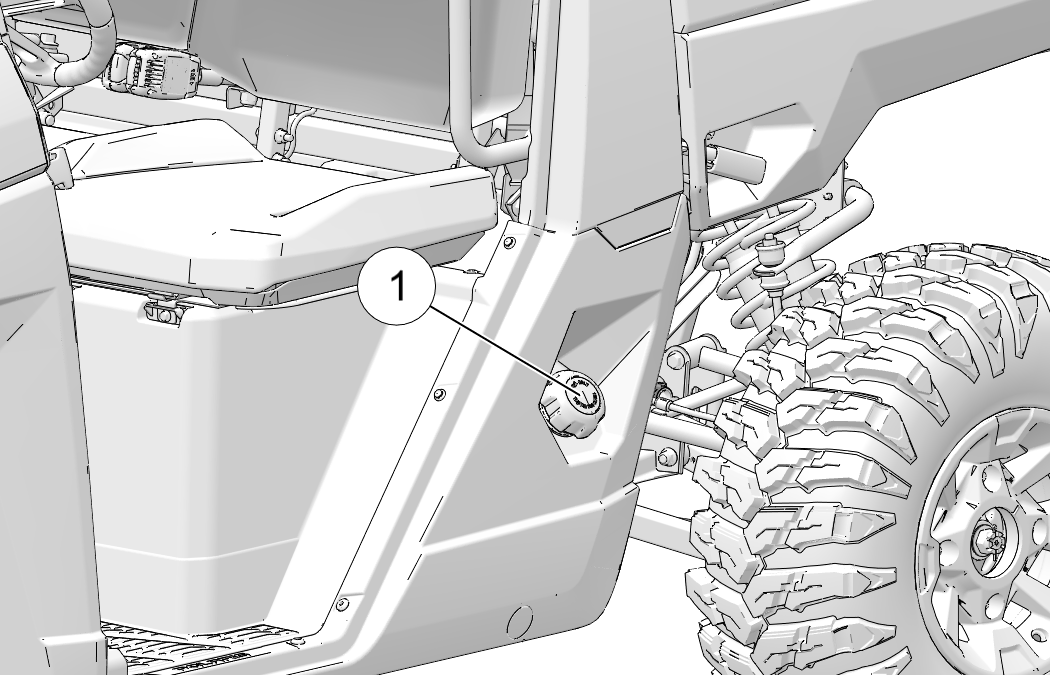

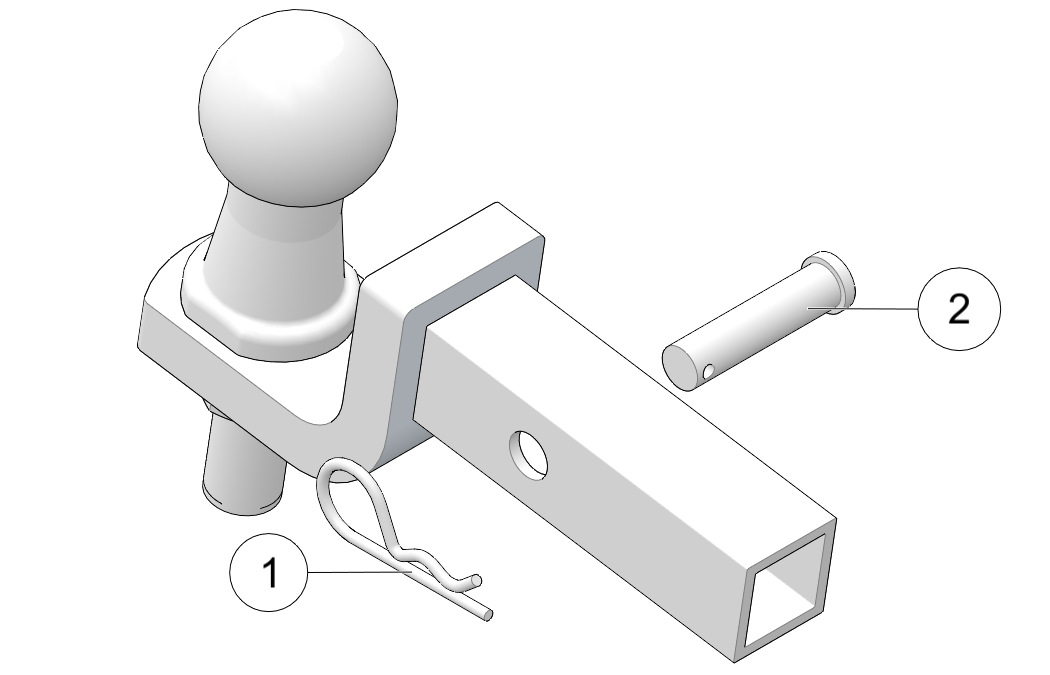

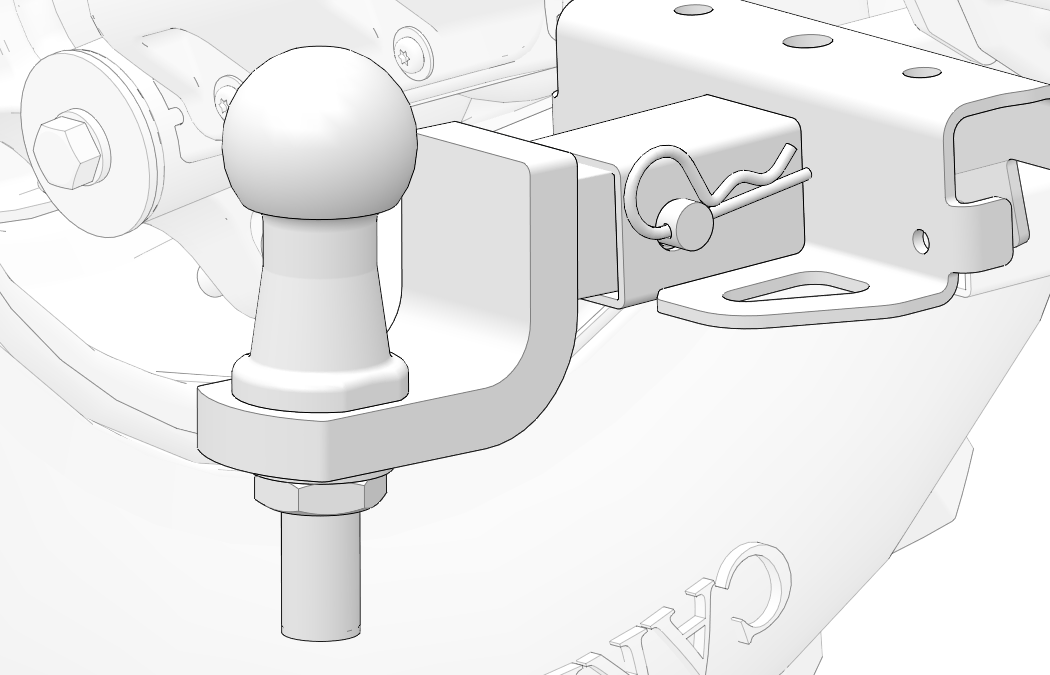

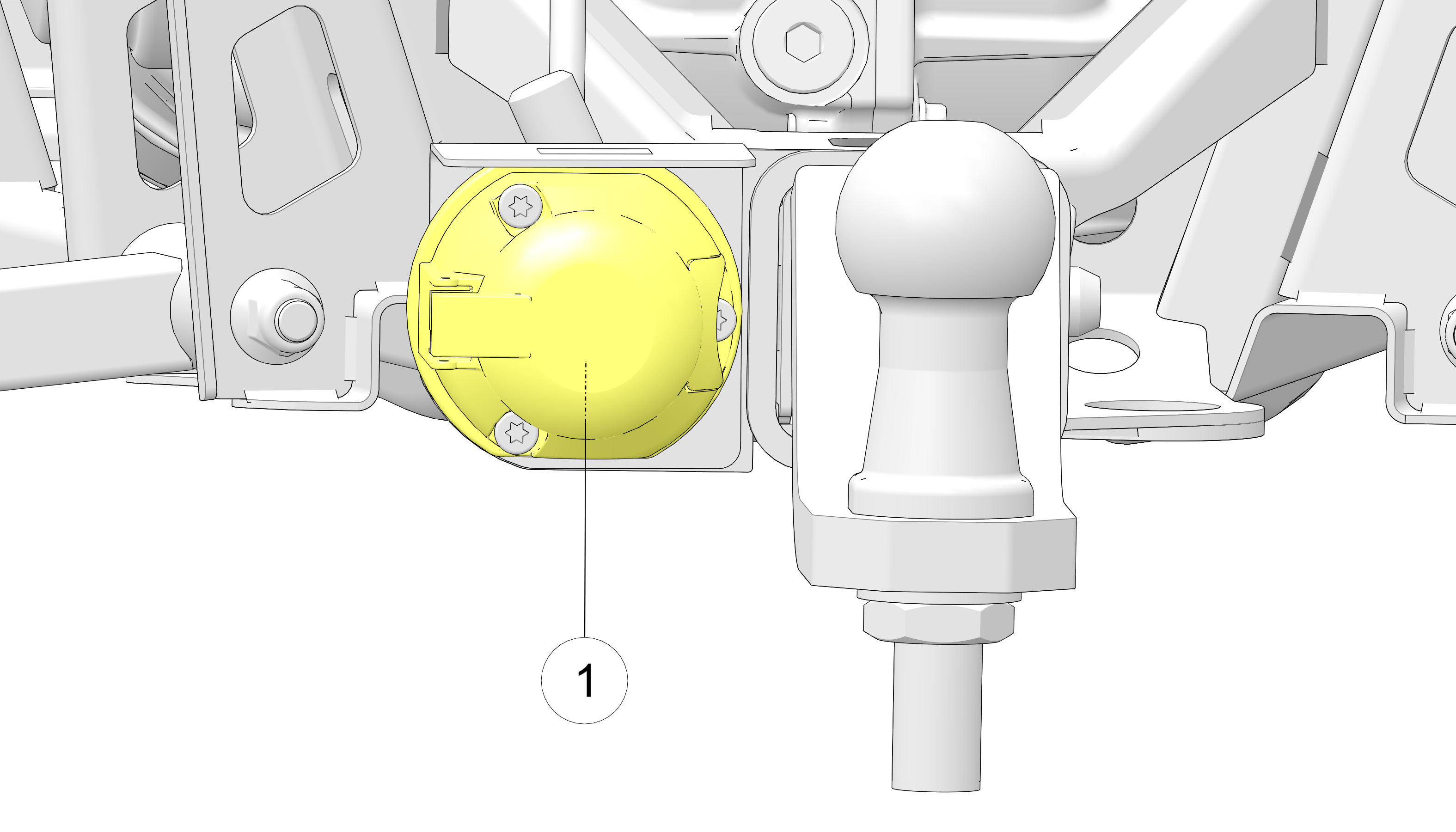

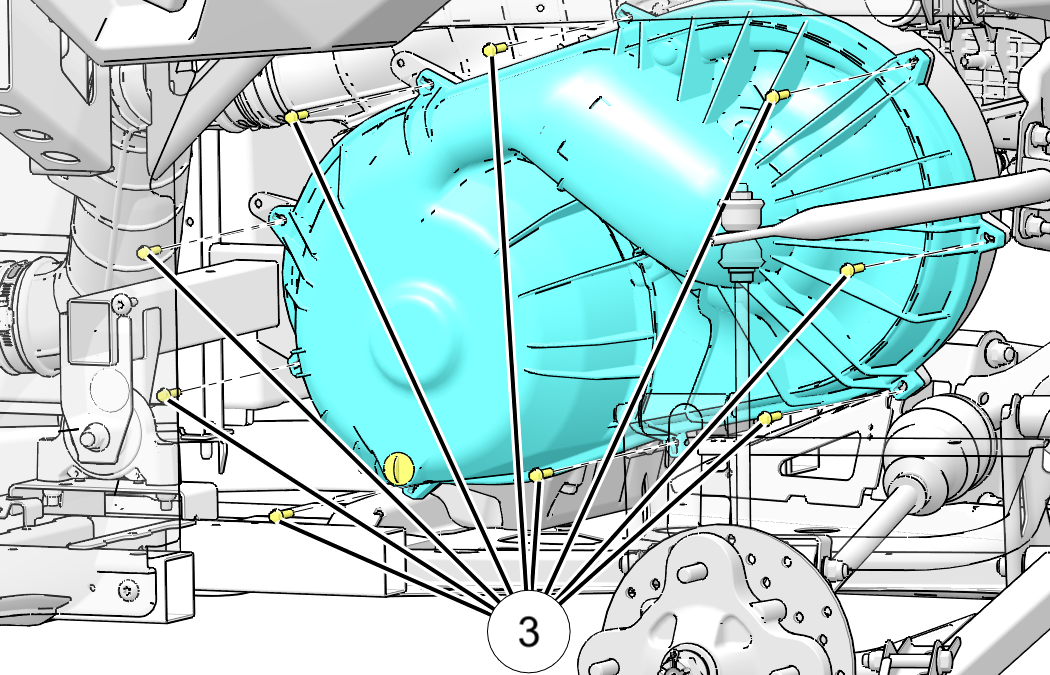

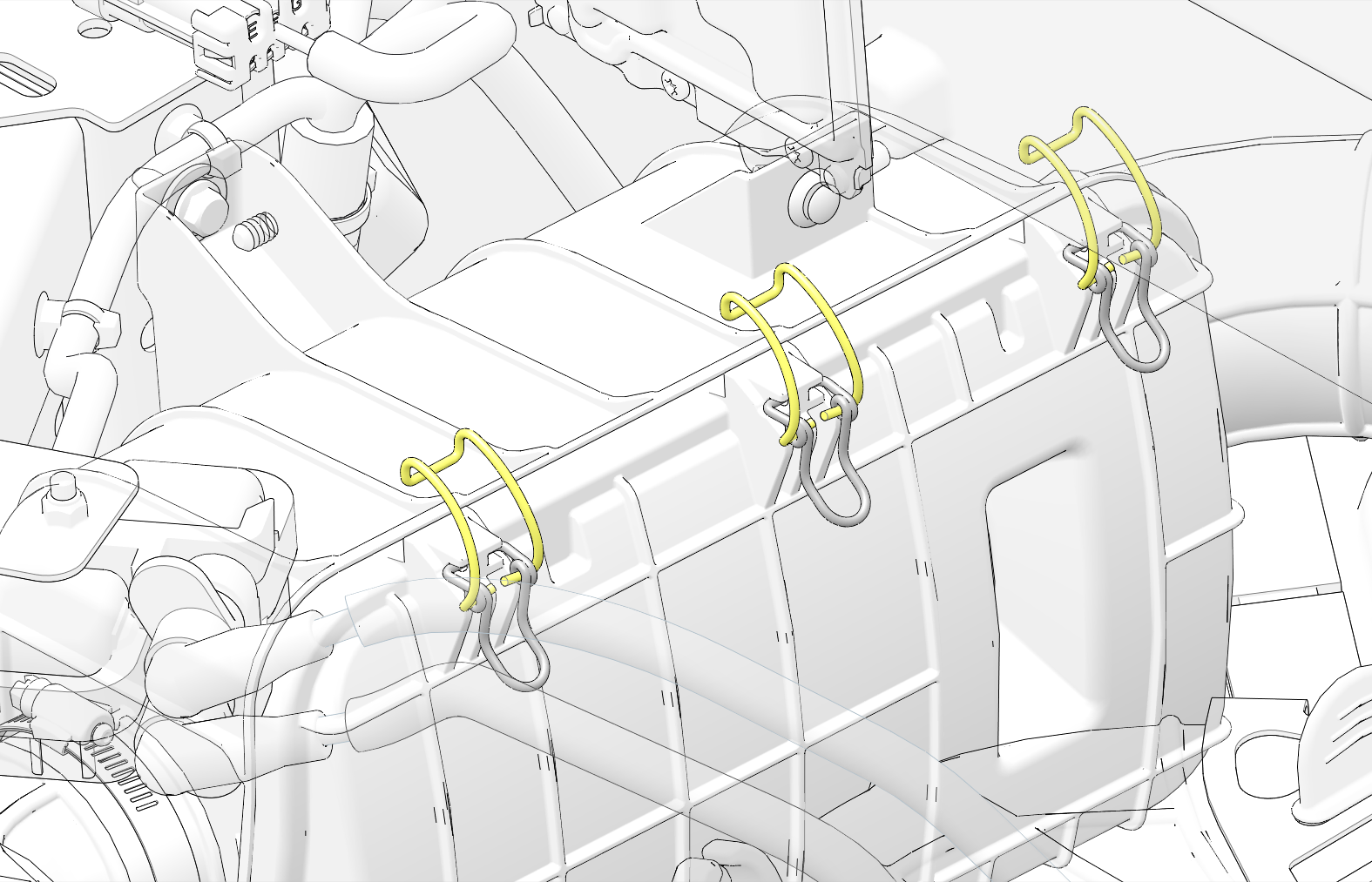

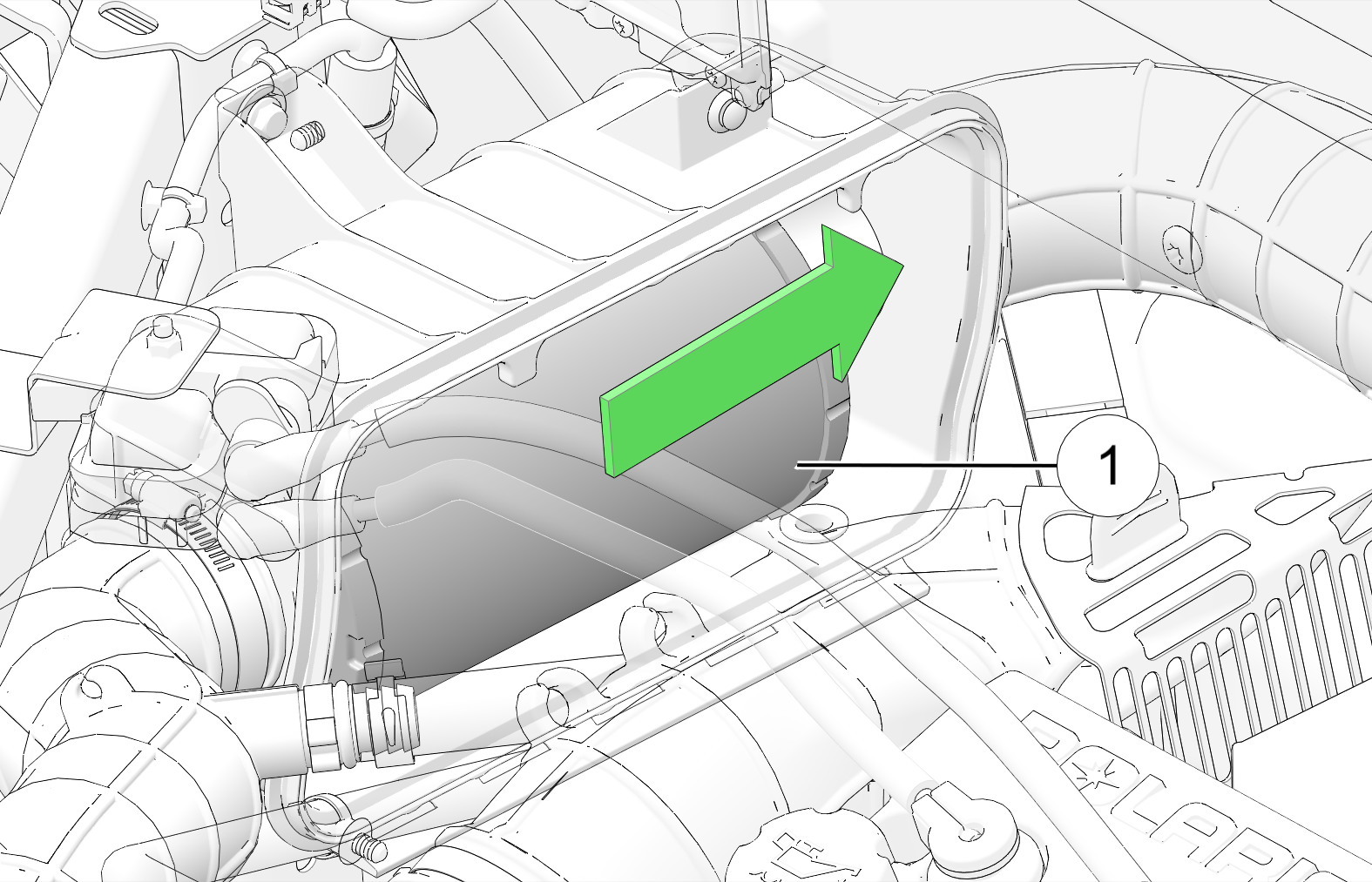

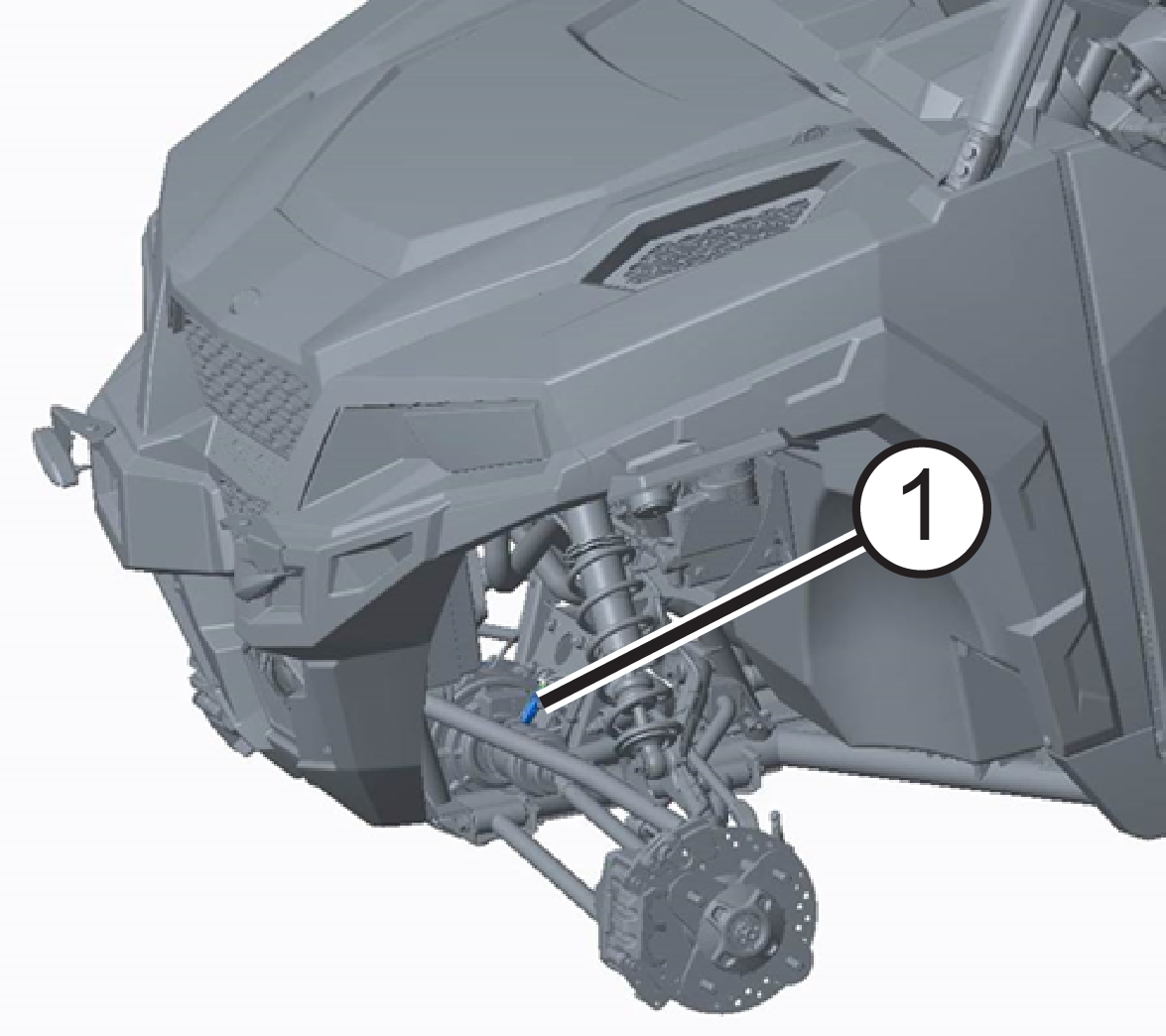

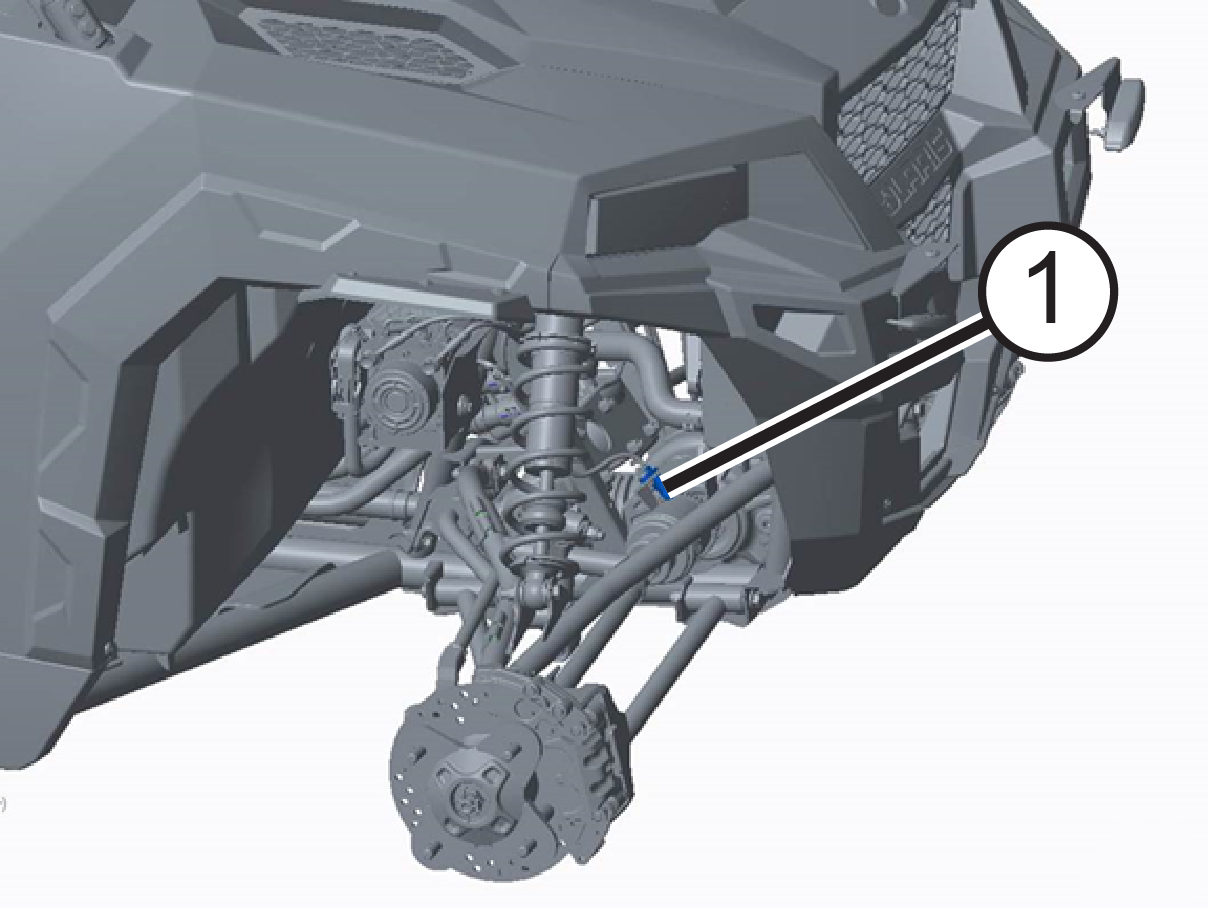

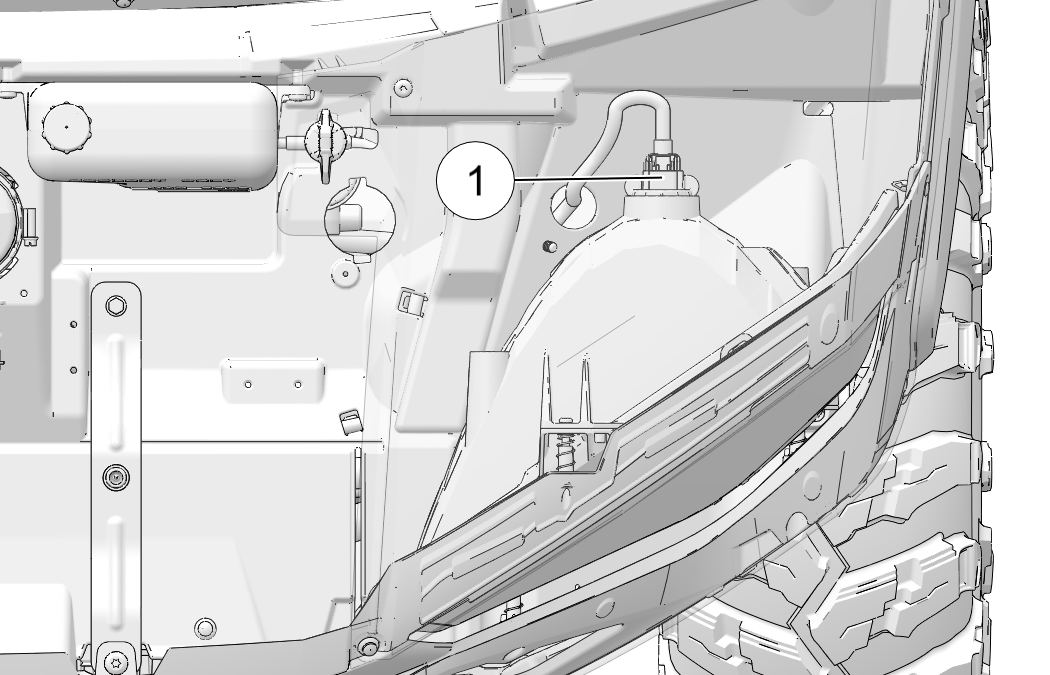

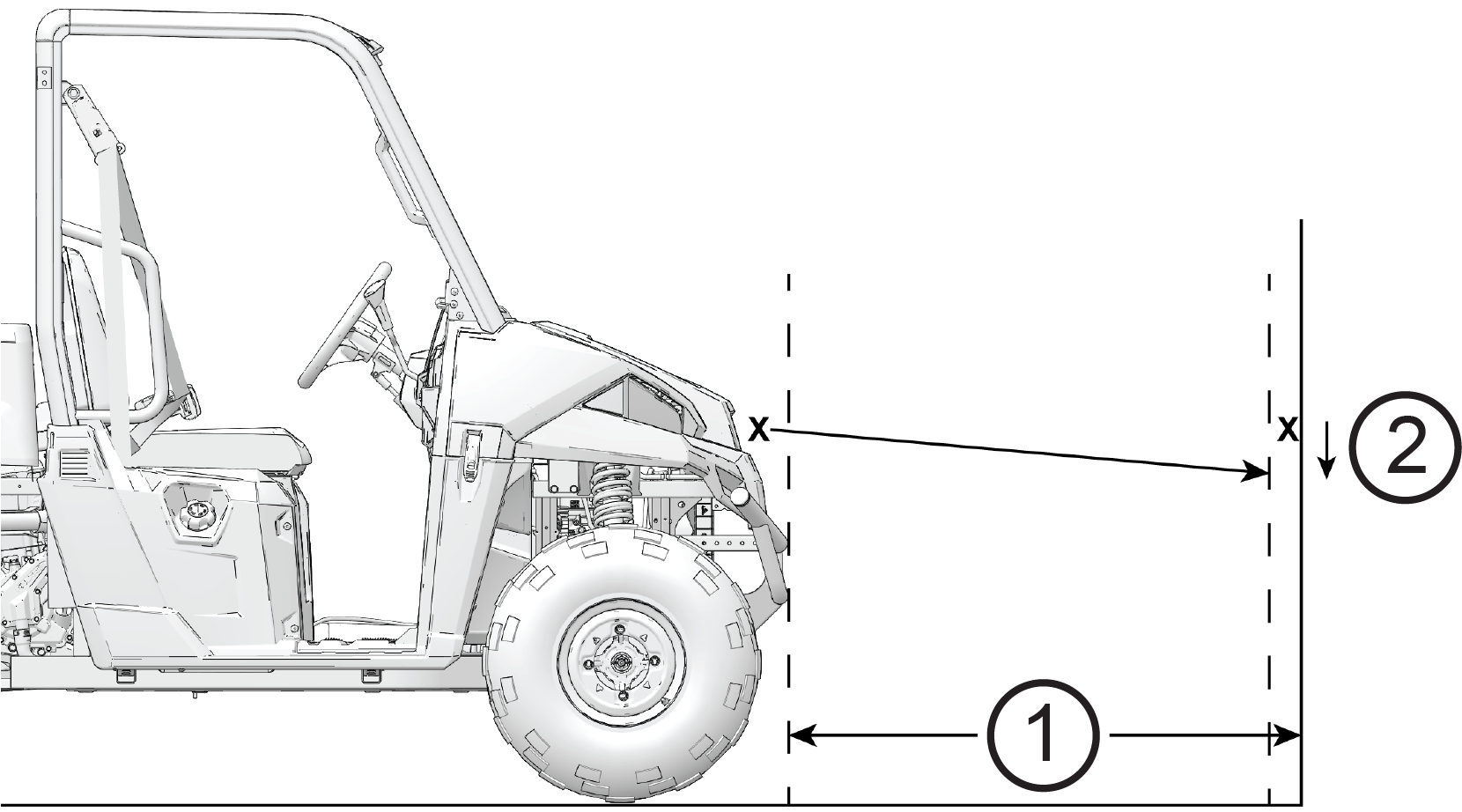

There is a recovery tow loop at the front and back of the vehicle

to attach a winch or strap.

Use these loops to

recover this vehicle if it is stuck, to pull it onto a tow truck,

trailer, or to use this vehicle to recover another vehicle. These

loops are for emergency recovery only and are not for towing vehicles

to another location.

Improper recovery may lead to loss of control or vehicle damage.

Only attach straps to specified locations. Do not attach to any other

point on the vehicle. Only recover a vehicle of equal or lesser size

and weight. When recovering a disabled vehicle, place the disabled

vehicle’s transmission in neutral. Do not move a disabled vehicle

faster than 16 km/h.

Operating, Idling, Or Parking Near Combustible Materials

Engine, exhaust, and other vehicle components can

be very hot during and after use. Do not idle or park the vehicle

over anything that could contact the exhaust system and catch on fire,

such as tall grass, weeds, brush, leaves, debris, or other tall ground

cover. Do not let mud, grass, or other debris accumulate on the engine

or exhaust system. Inspect and remove as needed.

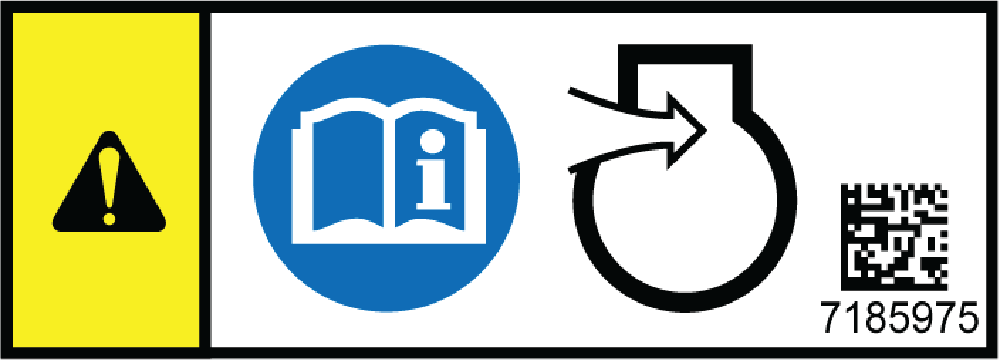

Vehicle rollaway can cause serious injury or death. This

vehicle can roll whenever the gear selector is not in the PARK (P)

position. Always shift to PARK (P) when stopping the engine or leaving

the vehicle. When leaving the vehicle on an incline is unavoidable,

use extra care. If leaving the vehicle unattended, block the rear

wheels on the downhill side and keep children, pets, and others away

from the gear selector.

Before shifting into reverse, use extra care to make sure the

area is clear of people or obstacles. When it’s safe to

proceed, back slowly.

After operation, inspect the vehicle for damage and debris to make sure the vehicle can be safely stored and operated again.

Some things to inspect include:

-

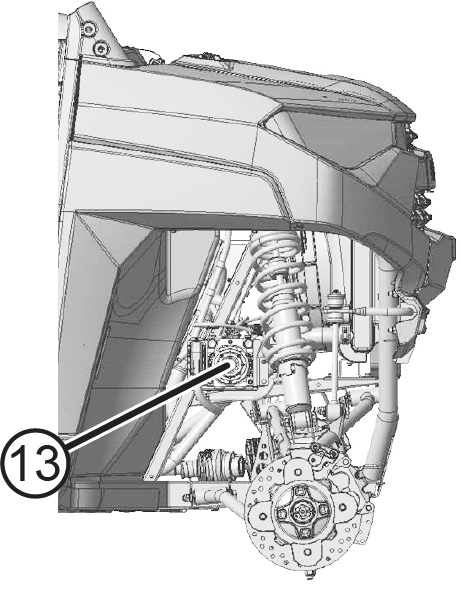

Debris that could catch fire, such as mud/grass near the engine

or exhaust system

-

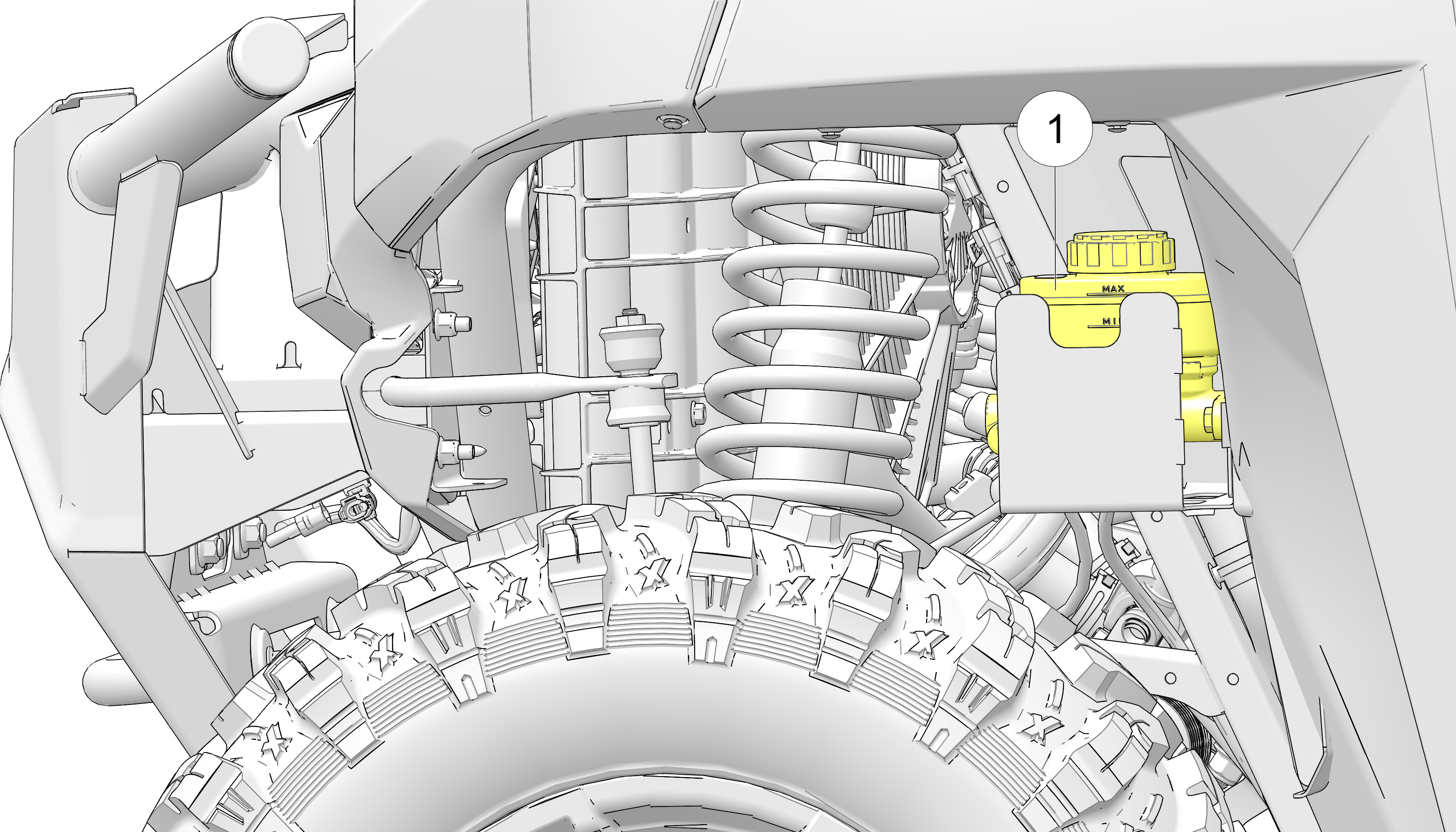

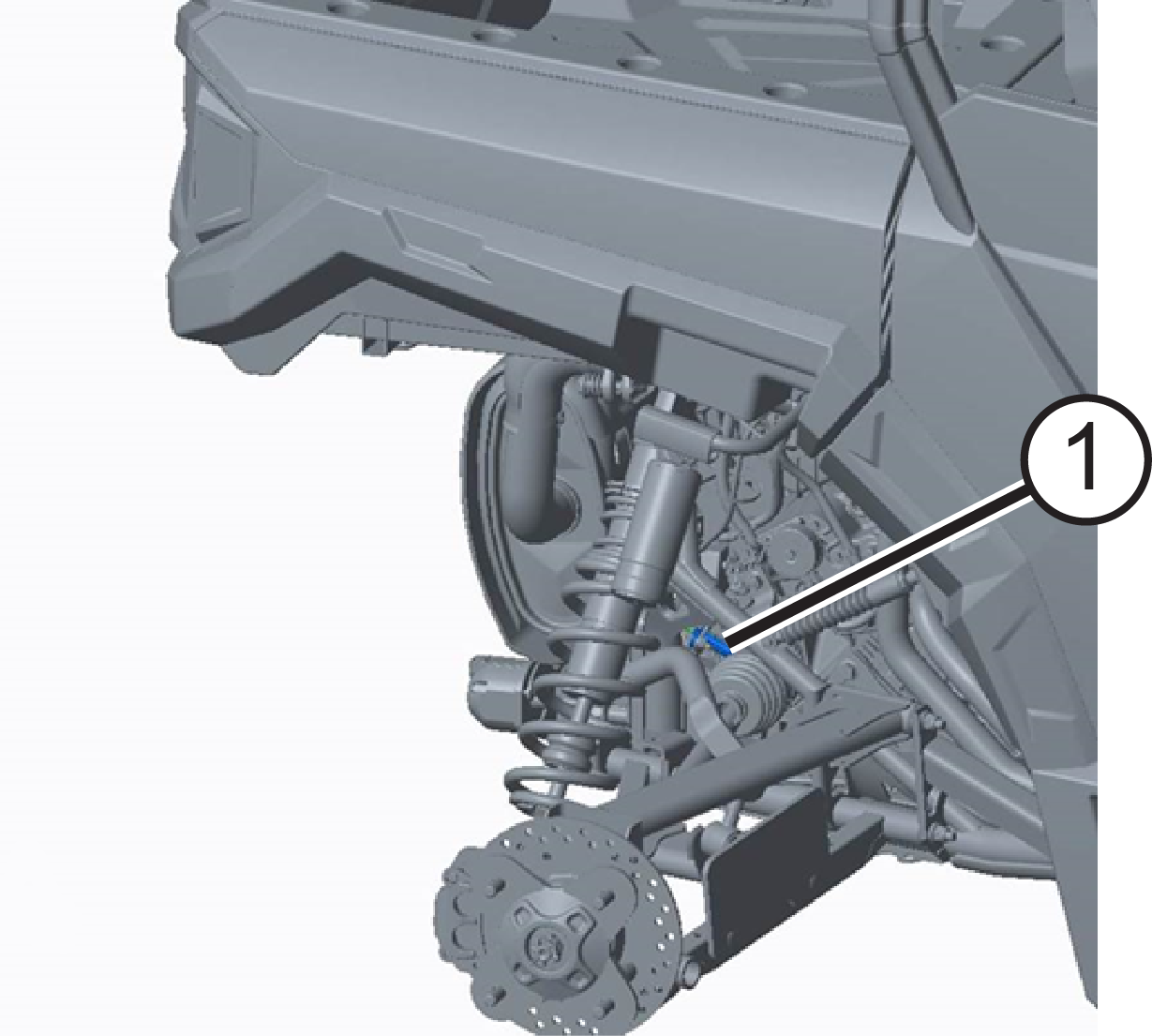

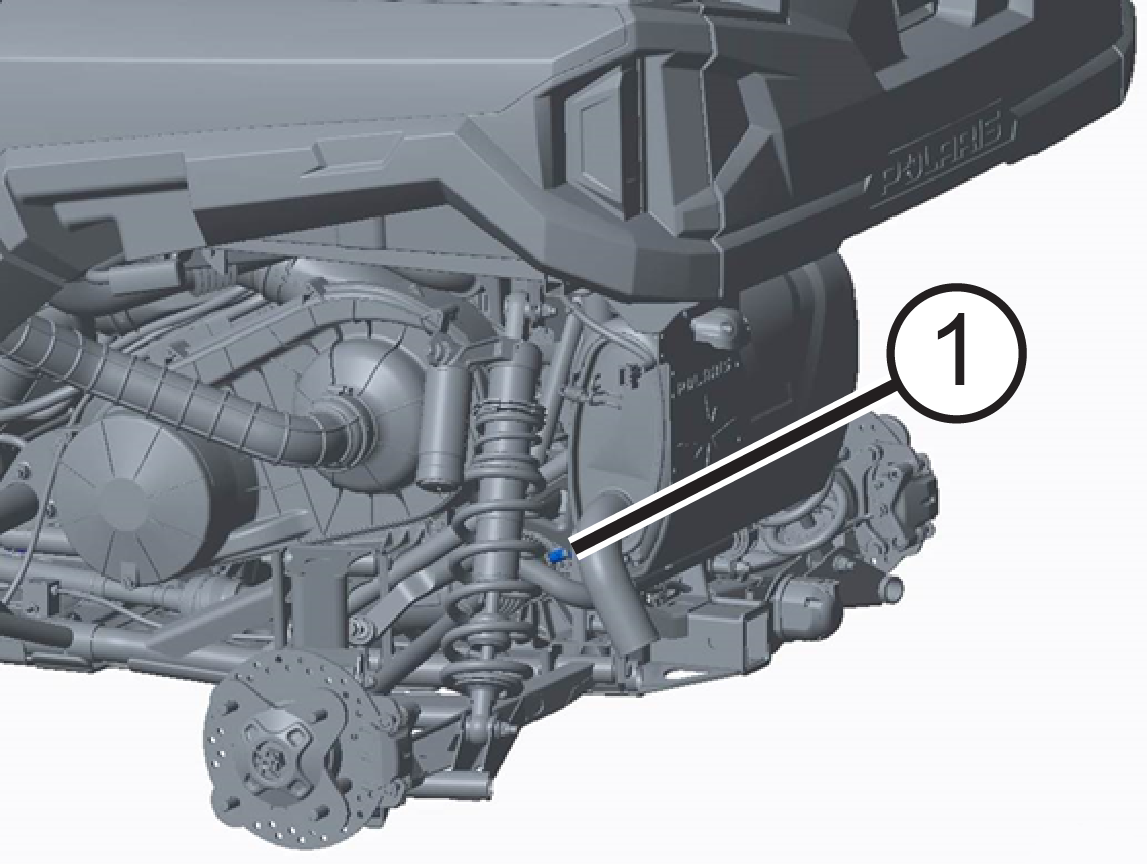

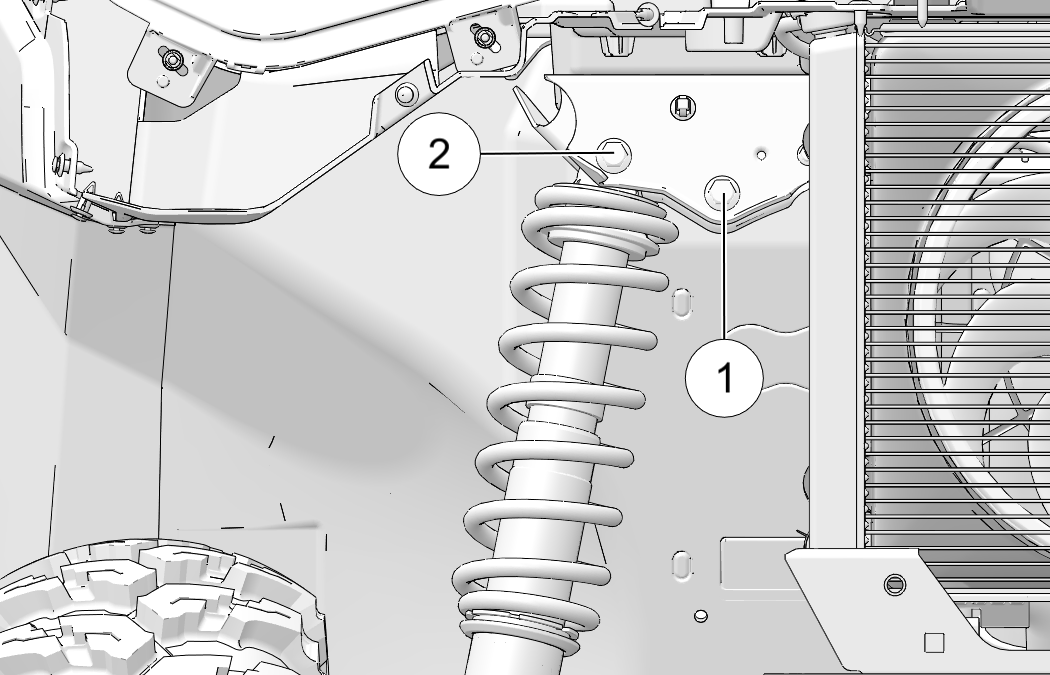

Damage to the suspension, steering, or any other part of the

vehicle

-

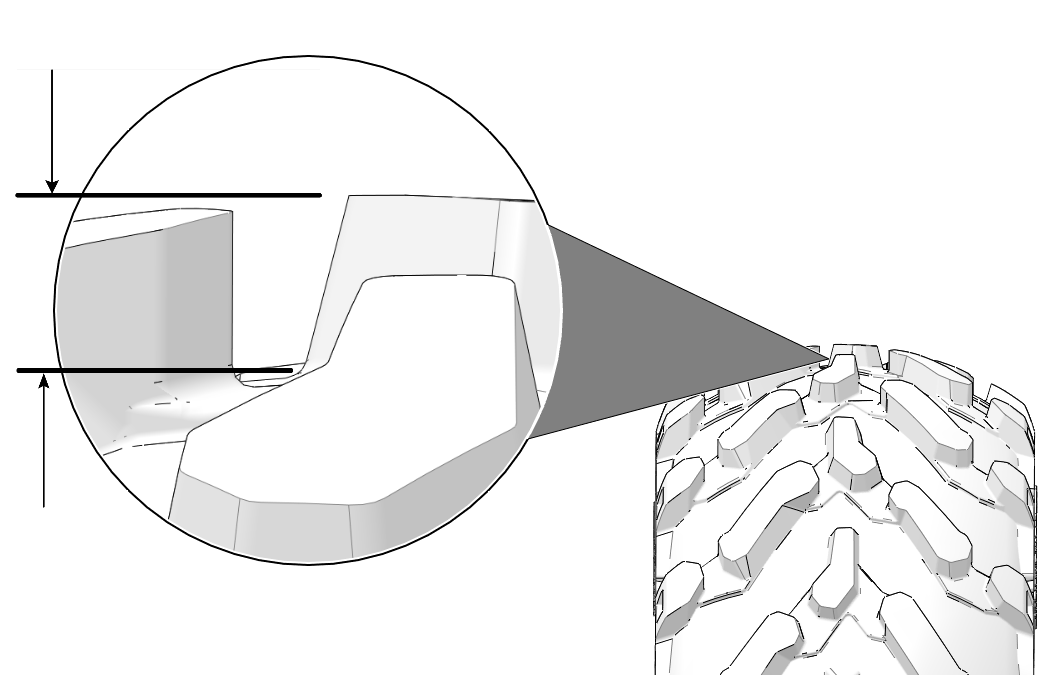

Tire condition, such as tread and sidewall damage

-

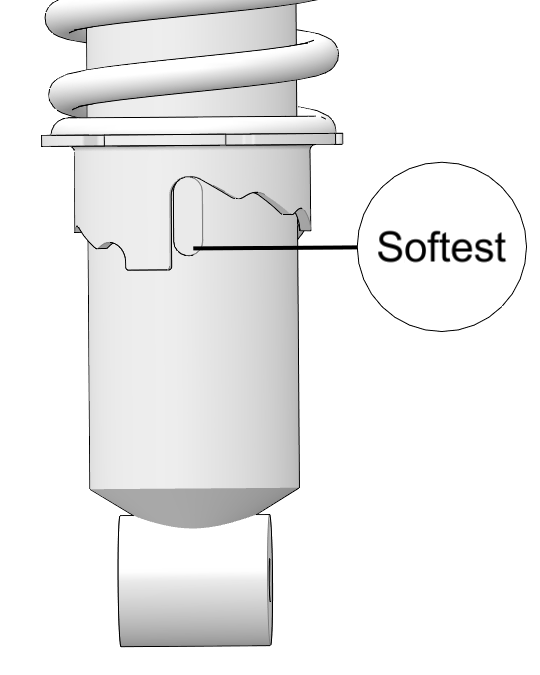

Shock absorber assembly condition

Be sure to have any issues checked and problems fixed before

operating again.

All engine exhaust contains carbon monoxide, a deadly gas.

Breathing carbon monoxide can cause headaches, dizziness, drowsiness,

nausea, confusion, and eventually death. Carbon monoxide is a colorless,

odorless, tasteless gas which may be present even if you do not see

or smell any engine exhaust. Deadly levels of carbon monoxide can

collect rapidly, and you can quickly be overcome and unable to save

yourself. Also, deadly levels of carbon monoxide can linger for hours

or days in enclosed or poorly ventilated areas. If you experience

any symptoms of carbon monoxide poisoning, leave the area immediately,

get fresh air, and SEEK MEDICAL TREATMENT.

-

Do not run engine indoors. Even if you try to ventilate engine

exhaust with fans or open windows and doors, carbon monoxide can rapidly

reach dangerous levels.

-

Do not run engine in poorly ventilated or partially enclosed

areas such as barns, garages, or carports. If you start a vehicle

in one of these, drive it out and close the door as soon as possible.

If you drive it into one of these, turn it off as soon as possible.

-

Do not run engine outdoors where engine exhaust can be drawn

into a building through openings such as windows and doors.

The above list of hazards and overturning risk is not exhaustive.