POLARIS Sales Inc., 2100 Highway 55, Medina, MN 55340 (POLARIS)

gives a 12 MONTH LIMITED WARRANTY on all components of your TIMBERSLED

Conversion System against defects in material or workmanship. This

warranty covers parts and dealer labor charges for repair or replacement

of defective parts and begins on the date of purchase by the original

retail purchaser. This warranty is transferable to another owner during

the warranty period through a TIMBERSLED dealer, but any such transfer

will not extend the original term of the warranty. The duration of

this warranty may vary by international region based upon local laws

and regulations.

See your dealer for details and separate terms and conditions for

any promotional warranties.

Registration

At the time of sale, the Warranty

Registration Form must be completed by your dealer and submitted to

TIMBERSLED within ten days of purchase. Upon receipt of this registration,

TIMBERSLED will record the registration for warranty. No verification

of registration will be sent to the purchaser as the copy of the Warranty

Registration Form will be your proof of warranty coverage. If you

have not signed the original registration and received the customer

copy, please contact your dealer immediately. NO WARRANTY COVERAGE

WILL BE ALLOWED UNLESS YOUR CONVERSION SYSTEM IS REGISTERED WITH TIMBERSLED.

Warranty Coverage and Exclusions:

Limitations

of Warranties and Remedies

This TIMBERSLED limited warranty

excludes any failures that are not caused by a defect in material

or workmanship. THIS WARRANTY DOES NOT COVER CLAIMS OF DEFECTIVE

DESIGN. This warranty also does not cover damage caused due to

incorrect installation, acts of God, accidental damage, normal wear

and tear, abuse or improper handling. This warranty also does not

cover any Conversion System, component, or part that has been altered

structurally, modified, neglected, improperly maintained, used for

racing, competition, or for purposes other than for which it was designed.

This warranty also excludes failures resulting from improper

lubrication; surface imperfections caused by external stress, heat,

cold or contamination; operator error or abuse; improper component

alignment, tension, adjustment; improper maintenance; modified components;

use of aftermarket components; unauthorized repairs; repairs made

after the warranty period expires or by an unauthorized repair center;

use of the product in competition or for commercial purposes. Warranty

will not apply to any product which has been damaged by abuse, accident,

fire or any other casualty not determined a defect of materials or

workmanship.

This warranty excludes coverage for consumable

components, general wear items, or any parts exposed to friction surfaces,

stresses, environmental conditions and/or contamination for which

they were not designed or not intended, including but not limited

to the following items:

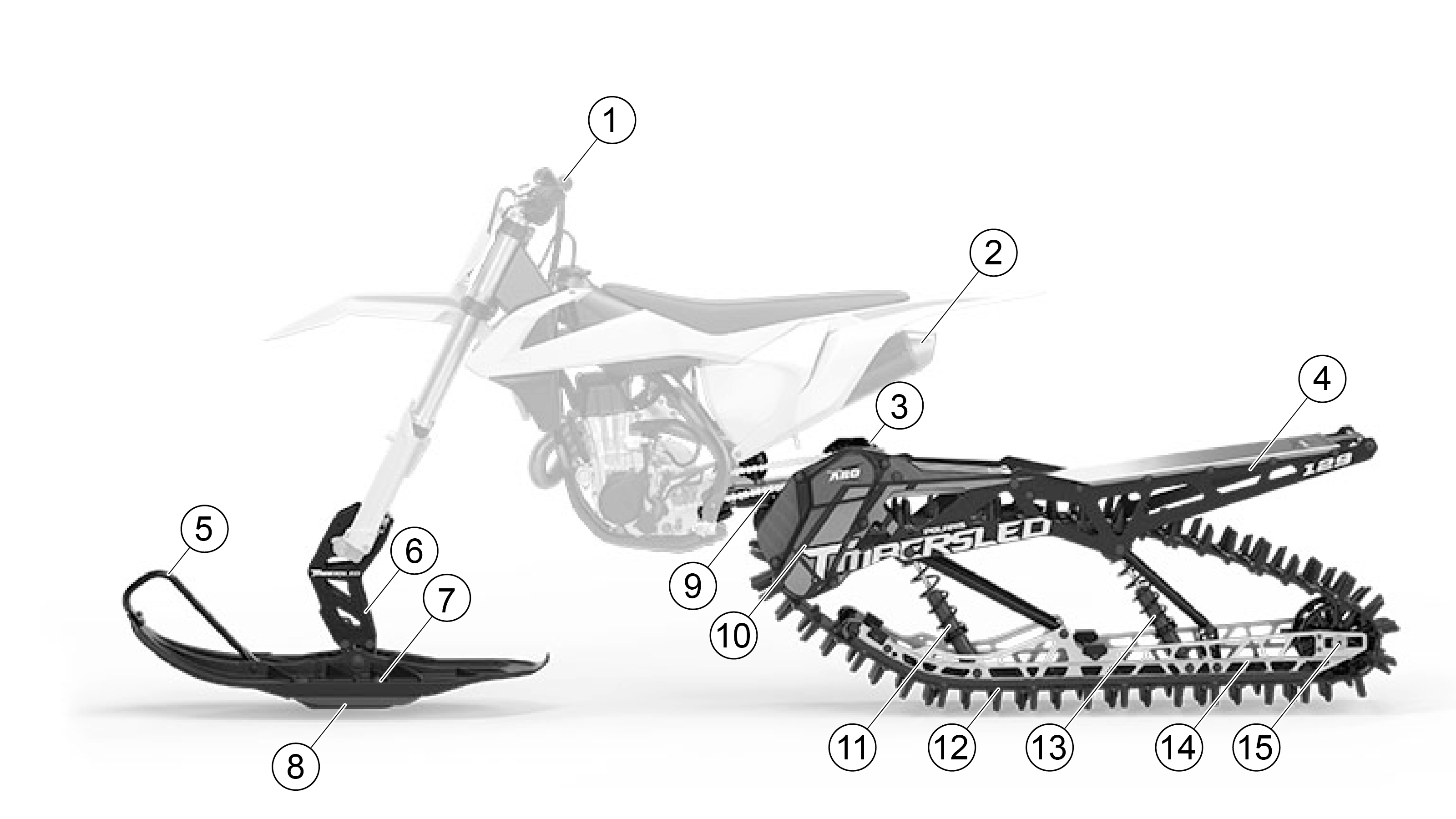

-

Skis

-

Tracks

-

Suspension Components

-

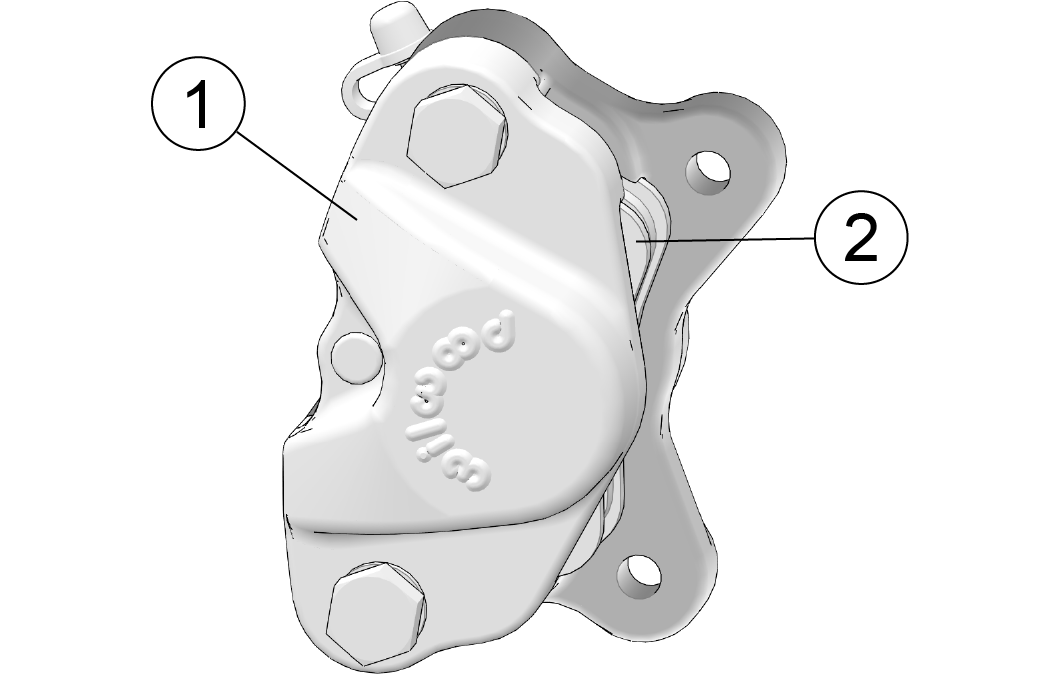

Brake Components

-

Idler Wheels

This warranty provides no coverage for personal loss or expense,

including mileage, transportation costs, hotels, meals, shipping or

handling fees, product pick-up or delivery, replacement rentals, loss

of product use, loss of profits, or loss of vacation or personal time.

THE EXCLUSIVE REMEDY FOR BREACH OF THIS WARRANTY SHALL BE, AT

POLARIS’ OPTION, REPAIR OR REPLACEMENT OF ANY DEFECTIVE MATERIALS,

COMPONENTS, OR PRODUCTS. THE REMEDIES SET FORTH IN THIS WARRANTY ARE

THE ONLY REMEDIES AVAILABLE TO ANY PERSON FOR BREACH OF THIS WARRANTY.

POLARIS SHALL HAVE NO LIABILITY TO ANY PERSON FOR INCIDENTAL, CONSEQUENTIAL

OR SPECIAL DAMAGES OF ANY DESCRIPTION, WHETHER ARISING OUT OF EXPRESS

OR IMPLIED WARRANTY OR ANY OTHER CONTRACT, NEGLIGENCE, OR OTHER TORT

OR OTHERWISE. THIS EXCLUSION OF CONSEQUENTAL, INCIDENTAL AND SPECIAL

DAMAGES IS INDEPENDENT FROM AND SHALL SURVIVE ANY FINDING THAT THE

EXCLUSIVE REMEDY FAILED OF ITS ESSENTIAL PURPOSE.

THE IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE IS EXCLUDED FROM THIS

LIMITED WARRANTY. ALL OTHER IMPLIED WARRANTIES (INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTY OF MERCHANTABILITY) ARE LIMITED IN

DURATION TO THE ABOVE 12 MONTH WARRANTY PERIOD. TIMBERSLED DISCLAIMS

ALL EXPRESS WARRANTIES NOT STATED IN THIS WARRANTY. SOME STATES DO

NOT PERMIT THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR ALLOW LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES,

SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU IF INCONSISTENT WITH

CONTROLLING STATE LAW.

How to Obtain Warranty Service

If your Conversion

System requires warranty service, you must take it to a TIMBERSLED

Servicing Dealer. When requesting warranty service you must present

your copy of the Warranty Registration to the dealer. (THE COST OF

TRANSPORTATION TO AND FROM THE DEALER IS YOUR RESPONSIBILITY). TIMBERSLED

suggests that you use your original selling dealer; however, you may

use any TIMBERSLED Servicing Dealer to perform warranty service.

In the Country where your product was purchased:

Warranty or Service Bulletin repairs must be done by an authorized

TIMBERSLED dealer. If you move or are traveling within the country

where your product was purchased, Warranty and Service Bulletin repairs

may be requested from any authorized TIMBERSLED dealer that sells

the same line as your product.

Outside the Country where

your product was purchased:

If you are traveling temporarily

outside the country where your product was purchased, you should take

your product to an authorized TIMBERSLED dealer. You must show the

dealer photo identification from the country of the selling dealer’s

authorized location as proof of residence. Upon residence verification,

the servicing dealer will be authorized to perform the warranty repair.

If you move:

If you move to another country, be sure

to contact TIMBERSLED Customer Assistance and the customs department

of the destination country before you move. Product importation rules

vary considerably from country to country. You may be required to

present documentation of your move to TIMBERSLED in order to continue

your warranty coverage. You may also be required to obtain documentation

from TIMBERSLED in order to register your product in your new country.

You should warranty register your product at a local TIMBERSLED dealer

in your new country immediately after you move to continue your warranty

coverage and to ensure that you receive information and notices regarding

your Conversion System.

If you purchase from a private party:

If you purchase a TIMBERSLED product from a private party,

to be kept and used outside of the country in which the product was

originally purchased, all warranty coverage will be denied. You must

nonetheless register your product under your name and address with

a local TIMBERSLED dealer in your country to ensure that you receive

safety information and notices regarding your product.

Exported Products

EXCEPT WHERE SPECIFICALLY

REQUIRED BY LAW, THERE IS NO WARRANTY OR SERVICE BULLETIN COVERAGE

ON THIS PRODUCT IF IT IS SOLD OUTSIDE THE COUNTRY OF THE SELLING DEALER’S

AUTHORIZED LOCATION. This policy does not apply to products that have

received authorization for export from TIMBERSLED. Dealers may not

give authorization for export. You should consult an authorized dealer

to determine this product’s warranty or service coverage if

you have any questions. This policy does not apply to products registered

to government officials or military personnel on assignment outside

the country of the selling dealer’s authorized location. This

policy does not apply to Safety Bulletins.

Notice

If your product is registered outside

of the country where it was purchased and you have not followed the

procedure set above, your product will no longer be eligible for warranty

or service bulletin coverage of any kind, other than safety bulletins. Products registered to Government officials or military

personnel on assignment outside of the country where the product was

purchased will continue to be covered by the Limited Warranty.

Please work with your dealer to resolve any warranty issues. Should

your dealer require any additional assistance, they will contact the

appropriate TIMBERSLED department.

This warranty gives you specific

legal rights, and you may also have other rights which vary from state

to state or in different countries. If any of the above terms are

void because of federal, state, local law, all other warranty terms

will remain in effect.

For questions call TIMBERSLED Customer

Assistance:

United States & Canada: 1-800-POLARIS

(1-800-765-2747)

French: 1–800–268–6334