|

Throttle Position Sensor 1 Voltage High

|

51

|

3

|

P0123

|

This Trouble Code sets if the Throttle Position Sensor Signal

is above 4.61 Volts. Can be caused by Damaged Wiring, a faulty Throttle

Position Sensor or ECU / Connections.

|

|

Throttle Position Sensor 1 Voltage Low

|

51

|

4

|

P0122

|

This Trouble Code sets if the Throttle Position Sensor Signal

is below 0.7 Volts. Can be caused by Damaged Wiring, a faulty Throttle

Position Sensor or ECU / Connections.

|

|

TPS Unrealistic Transition

|

51

|

10

|

P0120

|

This Trouble Code sets when the Throttle Position Sensor

Signal changes too rapidly to be correct. The condition can be caused

by intermittent connections causing the TPS voltage to jump around

between readings. Check for damaged connectors or wiring.

|

|

Vehicle Speed Sensor Signal Fault

|

84

|

2

|

P0503

|

This Trouble Code Sets if the Vehicle Speed Signal is intermittent

or missing. Can be caused by Damaged Wiring/Connections or a Faulty/Loose

Vehicle Speed Sensor.

|

|

Intake Air Temp Sensor Circuit Voltage High

|

105

|

3

|

P0113

|

This Trouble Code sets if the Intake Air Temperature Sensor

Signal is above 4.9 Volts. Can be caused by Damaged Wiring, a faulty

Intake Air Temperature Sensor or ECU / Connections.

|

|

Intake Air Temp Sensor Circuit Voltage Low

|

105

|

4

|

P0112

|

This Trouble Code sets if the Intake Air Temperature Sensor

Signal is below 0.19 Volts. Can be caused by Damaged Wiring, a faulty

Intake Air Temperature Sensor or ECU / Connections.

|

|

IAT Sensor Abnormal Rate of Change

|

105

|

10

|

P0114

|

This Trouble Code sets if the Intake Air Temperature Sensor

Signal indicates an Unrealistic Rate of Change. Can be caused by Damaged

Wiring, a faulty Intake Air Temperature Sensor or ECU / Connections.

|

|

Barometric Sensor Circuit Voltage High

|

108

|

3

|

P2229

|

This Trouble Code Sets if the Barometric Pressure Sensor

Signal Circuit is Open or Shorted to Battery Voltage. Can be caused

by Damaged Wiring/Connections, a Faulty Ambient Pressure Sensor or

ECU.

|

|

Barometric Sensor Circuit Voltage Low

|

108

|

4

|

P2228

|

This Trouble Code Sets if the Barometric Pressure Sensor

Signal Circuit is Shorted to Ground. Can be caused by Damaged Wiring/Connections,

a Faulty Ambient Pressure Sensor or ECU.

|

|

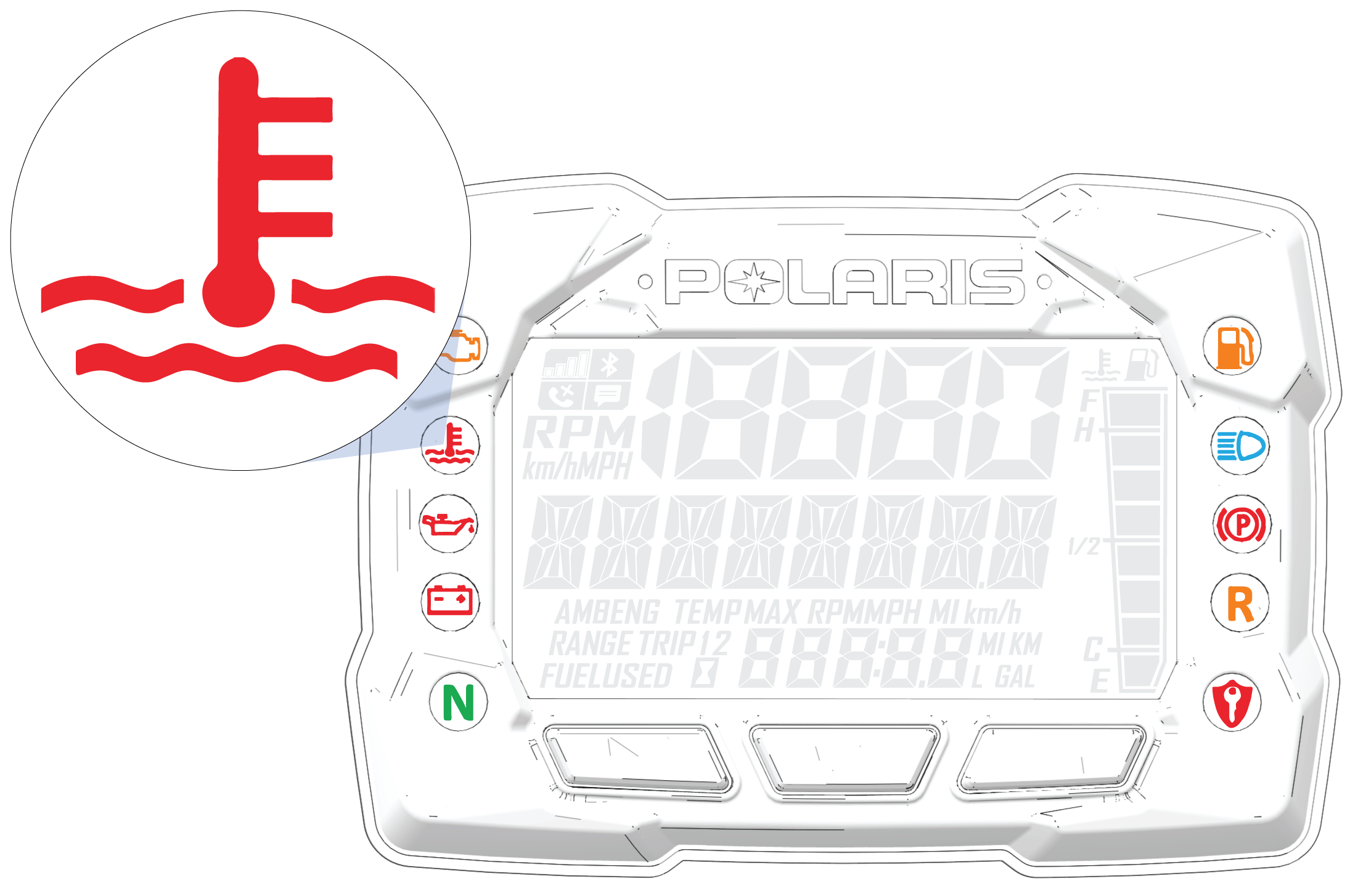

Engine Temperature Over-Temp Shutdown

|

110

|

0

|

P1217

|

This Trouble Code sets if the Engine Temperature indicates

a Critical Over Temperature Condition and the engine is running in

a limp-home mode to prevent damage. Can be caused by any failure that

would cause the engine to overheat.

|

|

Engine Temperature Sensor Circuit Voltage High

|

110

|

3

|

P0118

|

This Trouble Code sets if the Engine Coolant Temperature

Sensor Signal is above 4.8 Volts. Can be caused by Damaged Wiring,

a faulty Coolant Temperature Sensor or ECU / Connections.

|

|

Engine Temperature Sensor Circuit Voltage Low

|

110

|

4

|

P0117

|

This Trouble Code sets if the Engine Coolant Temperature

Sensor Signal is below 0.1 Volts. Can be caused by Damaged Wiring,

a faulty Coolant Temperature Sensor or ECU / Connections.

|

|

Engine Temperature Abnormal Rate of Change

|

110

|

10

|

P0119

|

This Trouble Code sets if the Engine Coolant Temperature

Sensor Signal is erratic. Can be caused by Damaged Wiring, a faulty

Coolant Temperature Sensor or ECU / Connections.

|

|

Engine Over-temperature Fault

|

110

|

16

|

P0217

|

This Trouble Code sets if the Engine Temperature indicates

a Severe Over Temperature Condition. Can be caused by any failure

that would cause the engine to overheat. This Trouble Code Does Not

indicate a problem with the Engine Temperature Sensor.

|

|

Fuel Rail Pressure Sensor Voltage High

|

157

|

3

|

P0193

|

This trouble code sets if the Fuel Pressure Sensor Voltage

is above 4.85V. Can be caused by Damaged Wiring, a faulty Fuel Pressure

Sensor or ECU / Connections.

|

|

Fuel Rail Pressure Sensor Voltage Low

|

157

|

4

|

P0192

|

This Trouble Code Sets if the Fuel Pressure Sensor Circuit

is below 0.1V. Can be caused by Damaged Wiring, a faulty Fuel Pressure

Sensor or ECU / Connections.

|

|

Fuel Rail Pressure Below Power Limit

|

157

|

18

|

P0196

|

This Trouble Code Sets if the Fuel Pressure drops below

3Bar (43.5PSI) for 10 seconds. Can be caused by a faulty Pump Flange

Assembly (PFA).

|

|

Battery Voltage High

|

158

|

3

|

P1567

|

This Trouble Code Sets if the if the Battery Voltage is

above 15.0V. Can be caused by Damaged Wiring, a faulty Battery or

ECU / Connections.

|

|

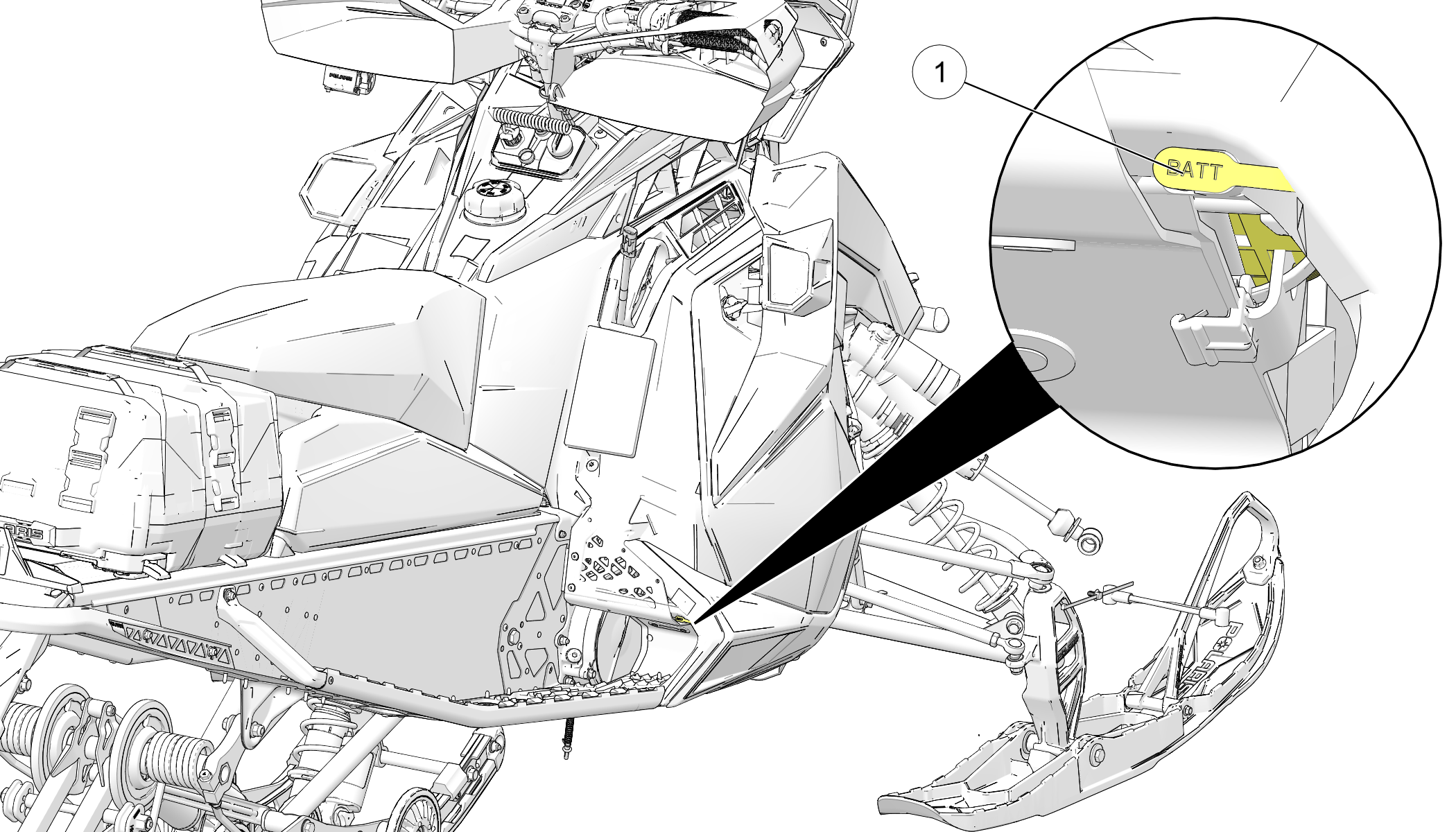

Battery Voltage Low

|

158

|

4

|

P1566

|

This Trouble Code Sets if the if the Battery Voltage is

below 10.0V. Can be caused by Damaged Wiring, a faulty Battery or

ECU / Connections.

|

|

Exhaust Over-Temperature Shutdown

|

173

|

0

|

P1517

|

This Trouble Code Sets if the engine was shut down due to

High Exhaust Temperature. Can be caused by a Faulty Exhaust Temperature

Sensor/Connections or Lean Air/Fuel Ratio causing high exhaust temperature.

|

|

Exhaust Temp Sensor Signal High

|

173

|

3

|

P0546

|

This Trouble Code sets if the engine has been running above

3000 RPM for more than 2 minutes and the Exhaust Temperature Sensor

Signal is above 4.90 Volts. Can be caused by Damaged Wiring, a faulty

Engine Temperature Sensor or ECU / Connections.

|

|

Exhaust Temp Sensor Signal Low

|

173

|

4

|

P0545

|

This Trouble Code sets if the engine has been running above

3000 RPM for more than 2 minutes and the Exhaust Temperature Sensor

Signal is below 0.06 Volts. Can be caused by Damaged Wiring, a faulty

Engine Temperature Sensor or ECU / Connections.

|

|

Exhaust Temp Sensor Unrealistic Transition

|

173

|

10

|

P1546

|

This Trouble Code sets if the Exhaust Temperature Sensor

Signal changes too quickly to be considered a Realistic Value. Can

be caused by Damaged Wiring, a faulty Exhaust Temperature Sensor or

ECU / Connections.

|

|

Fuel Temperature Sensor Voltage High

|

174

|

3

|

P1322

|

This trouble code sets if the Fuel Temperature Sensor Voltage

is above 4.81V. Can be caused by Damaged Wiring, a faulty Fuel Pressure

Sensor or ECU / Connections.

|

|

Fuel Temperature Sensor Voltage Low

|

174

|

4

|

P1323

|

This trouble code sets if the Fuel Temperature Sensor Voltage

is Below 0.01V. Can be caused by Damaged Wiring, a faulty Fuel Pressure

Sensor or ECU / Connections.

|

|

ECU Memory Checksum Error

|

628

|

13

|

P0601

|

This Trouble Code Sets if an Internal Memory Fault is detected

in the Engine Controller. Can only be caused by a defective ECU.

|

|

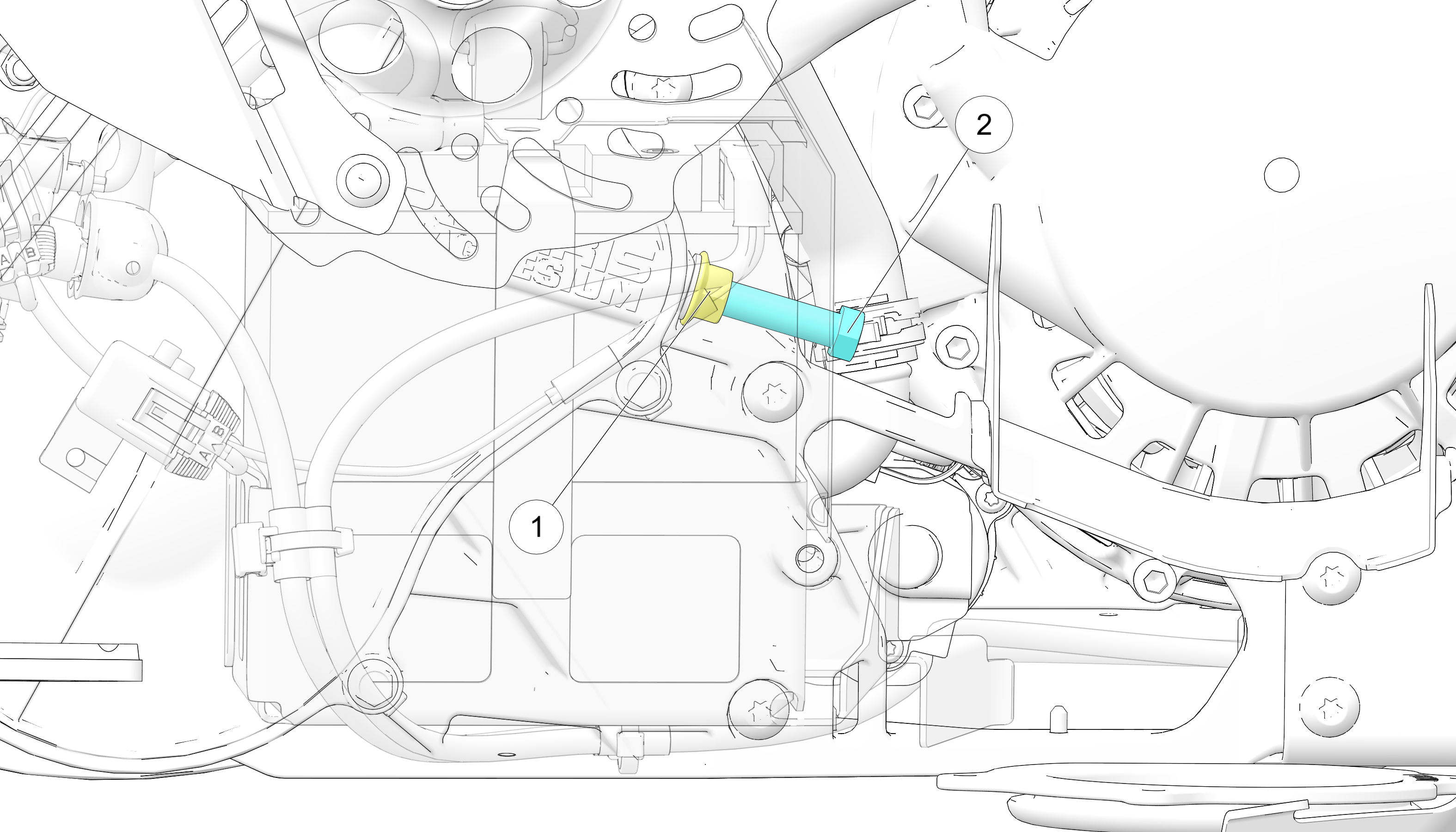

Crankshaft Sensor Signal Fault

|

636

|

2

|

P0335

|

This Trouble Code sets if the Engine is Running and No Signal

is Detected from the 5X Crankshaft Sensor. Can be caused by Damaged

Wiring, a faulty Crankshaft Sensor or ECU / Connections.

|

|

Crankshaft Position Sensor Circuit Fault

|

636

|

8

|

P0336

|

This Trouble Code sets if the Engine is Running and the

number of pulses from the 5X Crankshaft Sensor is not correct. Can

be caused by Damaged Wiring, a faulty Crankshaft Sensor or ECU / Connections.

|

|

MAG Cylinder Port Injector Short to B+

|

651

|

3

|

P0262

|

This Trouble Code sets if a Short to Voltage is detected

in the MAG Cylinder Port Injector Control Circuit. Can be caused by

Damaged Wiring, a faulty Fuel Injector or ECU / Connections.

|

|

MAG Cylinder Port Injector Open Circuit

|

651

|

5

|

P0261

|

This Trouble Code sets if an Open Circuit Condition is detected

in the MAG Cylinder Port Injector Control Circuit. Can be caused by

Damaged Wiring, a faulty Fuel Injector or ECU / Connections.

|

|

PTO Cylinder Port Injector Short to B+

|

652

|

3

|

P0265

|

This Trouble Code sets if a short to Voltage is detected

in the PTO Cylinder Port Injector Control Circuit. Can be caused by

Damaged Wiring, a faulty Fuel Injector or ECU / Connections.

|

|

PTO Cylinder Port Injector Open Circuit

|

652

|

5

|

P0264

|

This Trouble Code sets if an Open Circuit Condition is detected

in the PTO Cylinder Port Injector Control Circuit. Can be caused by

Damaged Wiring, a faulty Fuel Injector or ECU / Connections.

|

|

Ignition Coil 1 (MAG) Driver Circuit Open

|

1268

|

5

|

P1351

|

This Trouble Code Sets if Ignition Coil 1 (MAG) Driver Circuit

is Open. Can be caused by Damaged Wiring/Connections, a Faulty MAG

Ignition Coil or ECU.

|

|

Ignition Coil 2 (PTO) Driver Circuit Open

|

1269

|

5

|

P1352

|

This Trouble Code Sets if Ignition Coil 2 (PTO) Driver Circuit

is Open. Can be caused by Damaged Wiring/Connections, a Faulty PTO

Ignition Coil or ECU.

|

|

Max. Detonation Correction Limit Reached, MAG Cylinder

|

1352

|

0

|

P1336

|

This Trouble Code Sets if the Engine Controller Reaches

the Maximum Detonation Control Limit by Fuel Correction on the Mag

Cylinder Can be caused by Incorrect Fuel (low octane or Ethanol content)

or Low Fuel Pressure.

|

|

Cylinder 1 (MAG) Knock Level Critical

|

1352

|

16

|

P2336

|

This Trouble Code Sets if Cylinder 1 (MAG) Knock Sensor

reaches a Critical Level. Can be caused by Excessive Knock (Fuel Problems),

a Lean Running Condition or Engine Mechanical Problems.

|

|

Max. Detonation Correction Limit Reached, PTO Cylinder

|

1353

|

0

|

P1337

|

This Trouble Code Sets if the Engine Controller Reaches

the Maximum Detonation Control Limit by Fuel Correction on the PTO

Cylinder. Can be caused by Incorrect Fuel (low octane or Ethanol content)

or Low Fuel Pressure.

|

|

Cylinder 2 (PTO) Knock Level Critical

|

1353

|

16

|

P2337

|

This Trouble Code Sets if Cylinder 2 (PTO) Knock Sensor

reaches a Critical Level. Can be caused by Excessive Knock (Fuel Problems),

a Lean Running Condition or Engine Mechanical Problems.

|

|

Sensor Supply Voltage 1 Low

|

3509

|

4

|

P06B1

|

This Trouble Code sets if the Sensor Supply 1 Voltage is

below an acceptable limit (approx. 4.50 Volts). Can be caused by Damaged

Wiring or Faulty/Shorted Sensors.

|

|

Sensor Supply Voltage 2 Low

|

3510

|

4

|

P06B4

|

This Trouble Code sets if the Sensor Supply 2 Voltage is

below an acceptable limit (approx. 4.50 Volts). Can be caused by Damaged

Wiring or Faulty/Shorted Sensors.

|

|

Vehicle Speed Sensor Supply Voltage Low

|

3511

|

4

|

P16B6

|

This Trouble Code sets if the Sensor Supply 3 Voltage is

below an acceptable limit (approx. 4.5 Volts). Can be caused by Damaged

Wiring or Faulty Sensor/shorted to ground.

|

|

Oil Pump Driver Circuit Open

|

3589

|

5

|

P16BA

|

This Trouble Code Sets if the Oil Pump Driver Circuit is

Open. Can be caused by Damaged Wiring/Connections, a Faulty Oil Pump/Connections

or Faulty ECU/Connections.

|

|

Oil Pump Driver Circuit Fault

|

3589

|

12

|

P16BC

|

This Trouble Code Sets if a Failure is Detected in the Oil

Pump Driver Circuit. Can be caused by Damaged Wiring/Connections,

a Faulty Oil Pump/Connections or Faulty ECU/Connections.

|

|

Injector Output Supply 2 Voltage High

|

3598

|

3

|

P16A9

|

This Trouble Code sets if the Injector Output Supply 2 Voltage

is above an acceptable limit. Can be caused by Damaged Wiring or Faulty/Shorted

Connectors.

|

|

Injector Output Supply 2 Voltage Low

|

3598

|

4

|

P16A8

|

This Trouble Code sets if the Injector Output Supply 2 Voltage

is below an acceptable limit. Can be caused by Damaged Wiring or Faulty/Shorted

Connectors.

|

|

Regulator: Critical Voltage Too Low

|

32523

|

4

|

P1609

|

This Trouble Code Sets if the Regulator has detected Low

Voltage in the Critical Circuit. Can be caused by damaged Regulator

wiring or connections, electrical modifications or faulty Regulator.

|

|

Regulator: Critical Open Circuit

|

32523

|

5

|

P160B

|

This Trouble Code Sets if the Regulator has detected an

Open Circuit in the Critical Circuit. Can be caused by damaged wiring,

faulty headlight, Fuel Pump or Regulator connections.

|

|

Regulator: Critical Short Circuit

|

32523

|

6

|

P160C

|

This Trouble Code Sets if the Regulator has detected Excessive

Current in the Critical Circuit. Can be caused by damaged wiring,

faulty headlight, Fuel Pump or Regulator connections.

|

|

Regulator: Critical Voltage Too High

|

32523

|

15

|

P160D

|

This Trouble Code Sets if the Regulator has detected Excessive

Voltage in the Critical Circuit. Can be caused by damaged wiring,

faulty headlight, Fuel Pump or Regulator connections.

|

|

Regulator: Chassis Voltage Too Low

|

32523

|

20

|

P160E

|

This Trouble Code Sets if the Regulator has detected Low

Voltage in the Chassis Circuit. Can be caused by damaged wiring or

faulty grip heaters.

|

|

Regulator: Chassis Short Circuit

|

32523

|

22

|

P160F

|

This Trouble Code Sets if the Regulator has detected Excessive

Current Draw in the Chassis Circuit. Can be caused by damaged wiring

or faulty grip heaters.

|

|

Regulator: Chassis Voltage Too High

|

32523

|

31

|

P1610

|

This Trouble Code Sets if the Regulator has detected Excessive

Voltage in the Chassis Circuit. Can be caused by damaged wiring, Regulator

connections or Regulator.

|

|

Regulator: Stator Output Low

|

32531

|

36

|

P1510

|

This Trouble Code Sets if the Regulator has detected a Low

Voltage condition in the Stator. Can be caused by a Short to ground

in the Stator or damaged Stator wiring.

|

|

Regulator: Stator Open Circuit

|

32531

|

37

|

P1511

|

This Trouble Code Sets if the Regulator has detected an

Open Circuit condition in the Stator. Can be caused by an Open Circuit

in the Stator or damaged Stator wiring.

|

|

Exhaust Temperature Sensor 2 - Temperature Too High

|

520173

|

0

|

P1487

|

This Trouble Code sets if the Exhaust Temperature 2 Signal

is greater than 750C. Can be caused by a Faulty Exhaust Temperature

Sensor/Connections or Lean Air/Fuel Ratio causing high exhaust temperature.

|

|

Exhaust Temperature Sensor 2 Voltage High

|

520173

|

3

|

P1484

|

This Trouble Code Sets if the if the Exhaust Temp Sensor

2 Voltage is above 4.96V. Can be caused by Damaged Wiring, a faulty

Exhaust Temp Sensor or ECU / Connections.

|

|

Exhaust Temperature Sensor 2 Voltage Low

|

520173

|

4

|

P1485

|

This Trouble Code Sets if the if the Exhaust Temp Sensor

2 Voltage is Below 0.06V. Can be caused by Damaged Wiring, a faulty

Exhaust Temp Sensor or ECU / Connections.

|

|

Exhaust Temperature Sensor 2 Abnormal Rate of Change

|

520173

|

10

|

P1486

|

This Trouble Code sets if the Exhaust Temperature Sensor

Signal changes too quickly to be considered a Realistic Value. Can

be caused by Damaged Wiring, a faulty Exhaust Temperature Sensor or

ECU / Connections.

|

|

Exhaust Temperature Sensor 2 Mismatch with Sensor 1

|

520173

|

14

|

P1488

|

This Trouble Code Sets when Exhaust Temperature Sensor 2

signal is 250C greater than Exhaust Temp Sensor 1 signal. The condition

can be caused by Damaged Wiring, faulty Exhaust Temperature Sensor

or ECU / Connections.

|

|

ECU Supply Voltage High

|

520174

|

3

|

P1341

|

This Trouble Code sets if the ECU Supply Voltage is above

17.00V. Can be based by faulty wiring, faulty regulator or ECU / Connections

|

|

ECU Supply Voltage Low

|

520174

|

4

|

P1342

|

This Trouble Code sets if the ECU Supply Voltage is below

10.00V. Can be based by faulty wiring, faulty regulator or ECU / Connections.

|

|

Critical Supply Voltage High

|

520175

|

3

|

P1343

|

This Trouble Code sets if the Critical Supply Voltage is

above 17.00V. Can be based by faulty wiring, faulty regulator or ECU

/ Connections.

|

|

Critical Supply Voltage Low

|

520175

|

4

|

P1344

|

This Trouble Code sets if the Critical Supply Voltage is

below 10.00V. Can be cbased by faulty wiring, faulty regulator or

ECU / Connections.

|

|

Chassis Supply Voltage High

|

520176

|

3

|

P1345

|

This Trouble Code sets if the Chassis Supply Voltage is

above 18.00V. Can be based by faulty wiring, faulty regulator or ECU

/ Connections.

|

|

Chassis Supply Voltage Low

|

520176

|

4

|

P1346

|

This Trouble Code sets if the Chasssis Supply Voltage is

below 14.00V. Can be based by faulty wiring, faulty regulator or ECU

/ Connections.

|

|

Peak Injector Voltage High

|

520177

|

3

|

P1347

|

This Trouble Code sets if the Peak Injector Supply Voltage

is above 24.00V. Can be based by faulty wiring, faulty regulator or

ECU / Connections.

|

|

Peak Injector Voltage Low

|

520177

|

4

|

P1348

|

This Trouble Code sets if the Peak Injector Supply Voltage

is below 20.00V. Can be based by faulty wiring, faulty regulator or

ECU / Connections.

|

|

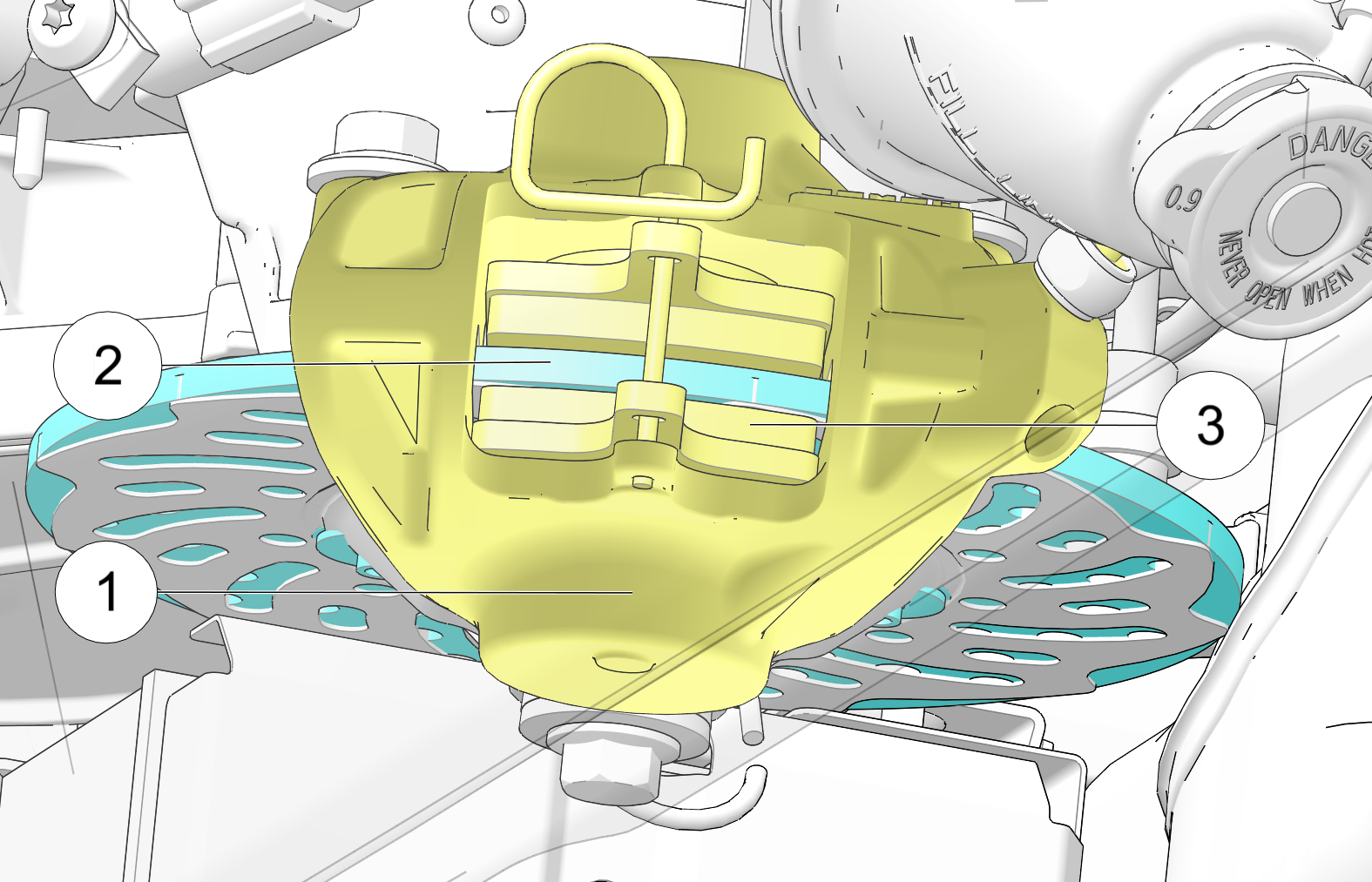

EV Actuator Position High in Open Position

|

520178

|

16

|

P2627

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is greater than 80.0% when trying to achieve Open position. This can

be caused by a faulty Exhaust Valve Actuator, Broken Cable or Broken

Exhaust Valve Assembly.

|

|

EV Actuator Position Low in Open Position

|

520178

|

18

|

P2628

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is less than 70.0% when trying to achieve Open position. This can

be caused by a faulty Exhaust Valve Actuator, Broken Cable or Broken

Exhaust Valve Assembly.

|

|

EV Actuator Position High in Mid Position

|

520179

|

16

|

P2629

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is greater than 55.0% when trying to achieve Mid position. This can

be caused by a faulty Exhaust Valve Actuator, Broken Cable or Broken

Exhaust Valve Assembly.

|

|

EV Actuator Position Low in Mid Position

|

520179

|

18

|

P2630

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is less than 45.0% when trying to achieve Mid position. This can be

caused by a faulty Exhaust Valve Actuator, Broken Cable or Broken

Exhaust Valve Assembly.

|

|

EV Actuator Position High in Closed Position

|

520180

|

16

|

P2631

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is greater than 30.0% when trying to achieve Closed position. This

can be caused by a faulty Exhaust Valve Actuator, Broken Cable or

Broken Exhaust Valve Assembly.

|

|

EV Actuator Position Low in Closed Position

|

520180

|

18

|

P2632

|

This Trouble Code sets if the Exhaust Valve Actuator Position

is less than 20.2% when trying to achieve Closed position. This can

be caused by a faulty Exhaust Valve Actuator, Broken Cable or Broken

Exhaust Valve Assembly.

|

|

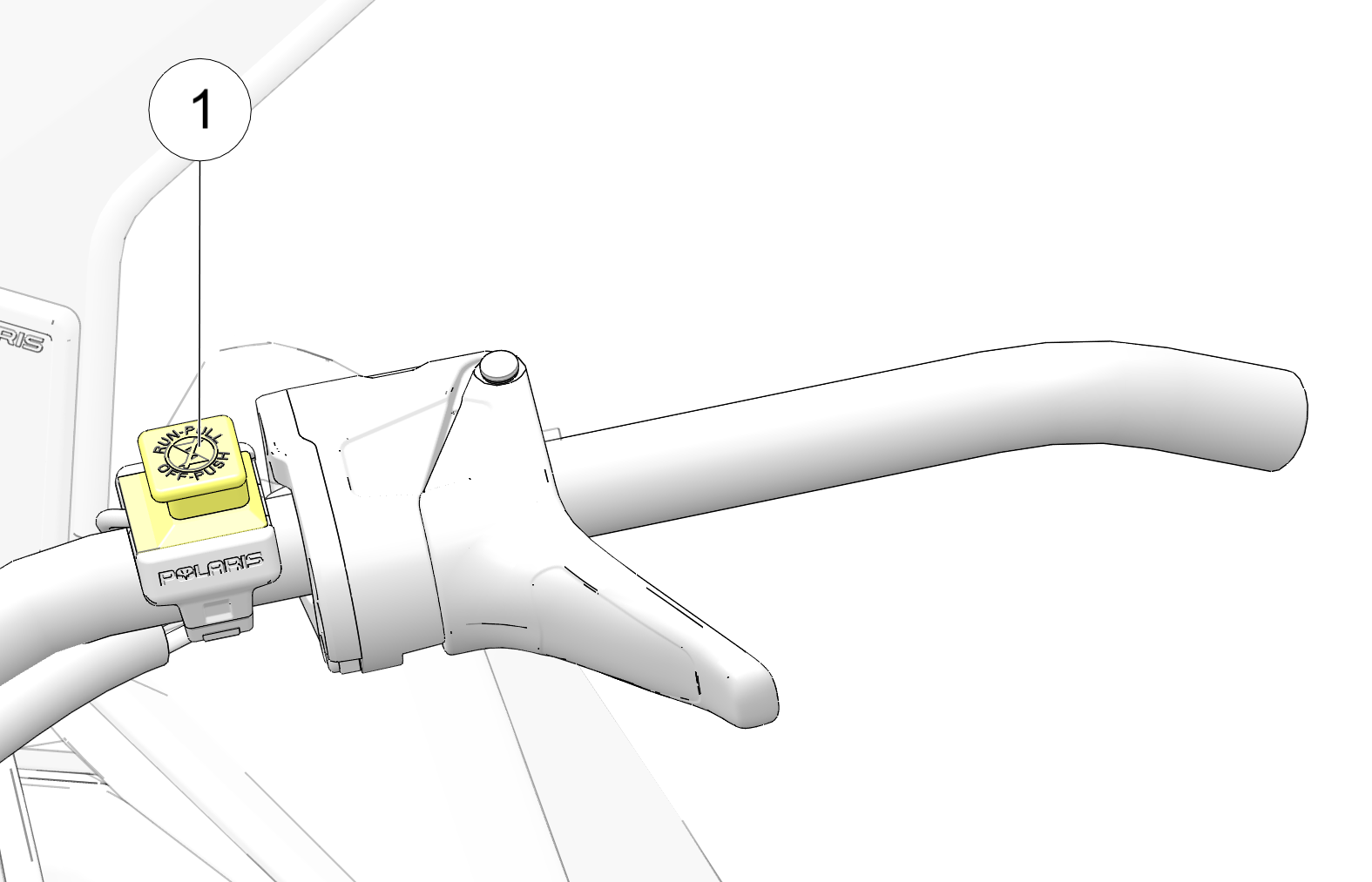

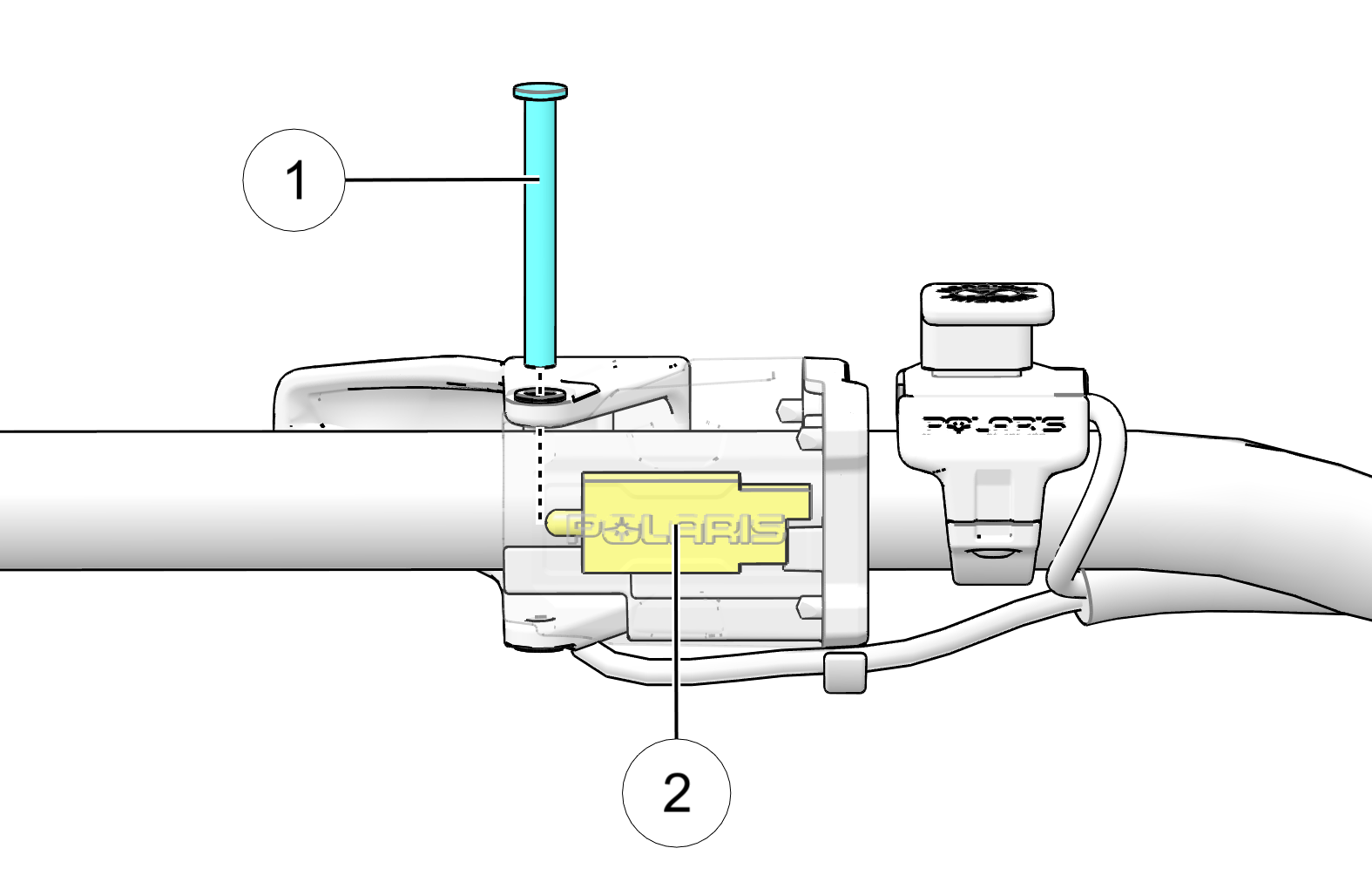

Throttle Release Switch Signal Circuit Short to Voltage

|

520194

|

3

|

P1555

|

This Trouble Code Sets if the Throttle Release Switch Signal

is Open Circuit or Shorted to Battery Voltage. Can be caused by Damaged

Wiring/Connections, a Faulty Throttle Safety Switch or ECU.

|

|

Throttle Release Switch Signal Circuit Short to Ground

|

520194

|

4

|

P1554

|

This Trouble Code Sets if the Throttle Safety Switch Signal

is Shorted to Ground. Can be caused by Damaged Wiring/Connections,

a Faulty Throttle Safety Switch or ECU.

|

|

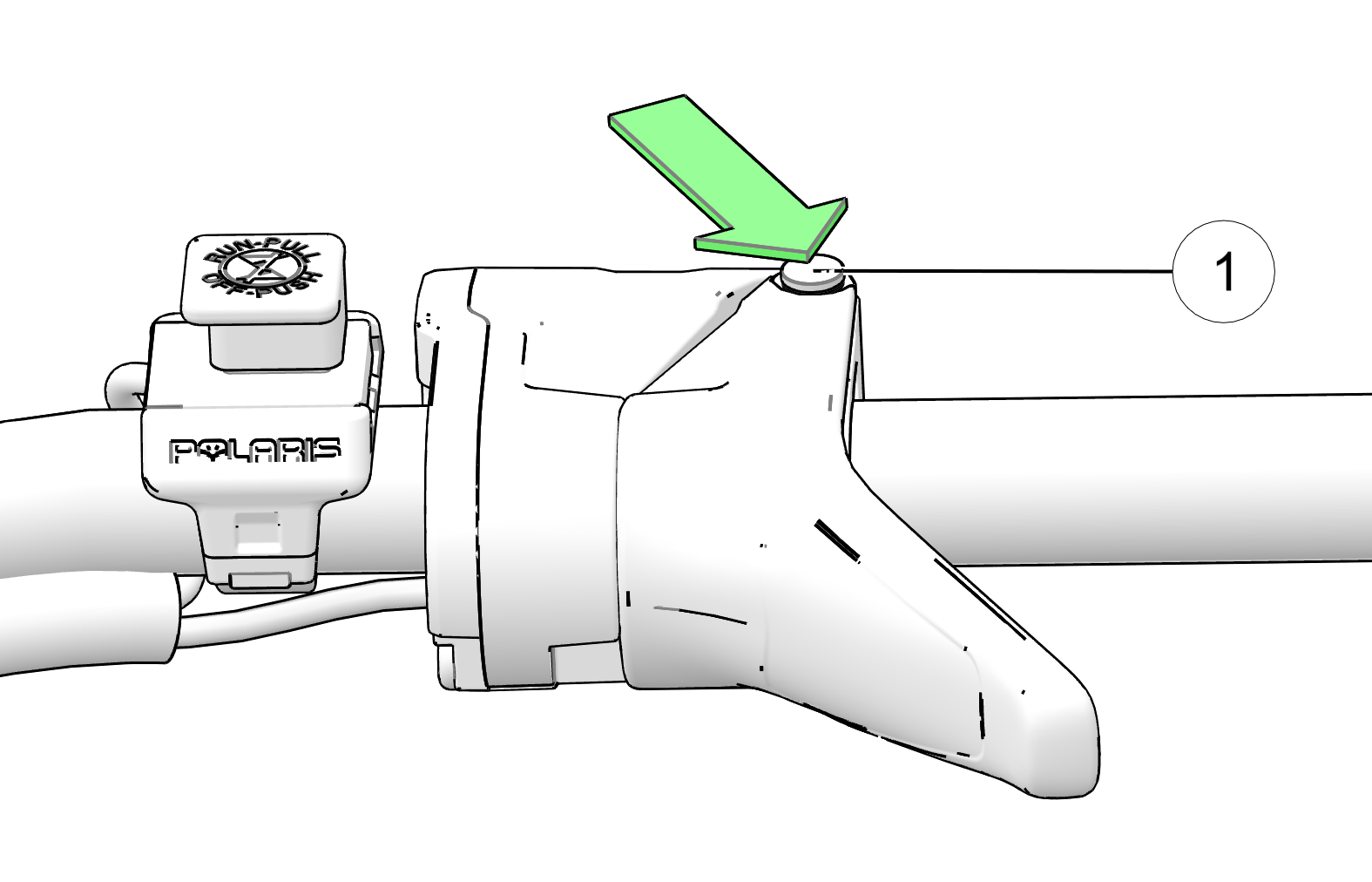

Throttle Stuck Error

|

520194

|

7

|

P1552

|

This Trouble Code Sets if the Throttle Release Switch Signal

Indicates a Throttle Stuck Open. Can be caused by a Stuck Throttle

or Misadjusted/Stuck Throttle Linkage.

|

|

Accessory Relay Driver Circuit Short to B+

|

520219

|

3

|

P1647

|

This Trouble Code Sets if the Accessory Relay Driver Circuit

is Shorted to Voltage. Can be caused by Damaged Wiring/Connections,

a Faulty Accessory Relay or ECU.

|

|

Accessory Relay Driver Circuit Open

|

520219

|

5

|

P1646

|

This Trouble Code Sets if the Accessory Relay Driver Circuit

is Open. Can be caused by Damaged Wiring/Connections, a Accessory

Ignition Relay or ECU.

|

|

Charge Relay Driver Circuit Short to B+

|

520220

|

3

|

P163D

|

This Trouble Code Sets if the Charge Relay Driver Circuit

is Shorted to Voltage. Can be caused by Damaged Wiring/Connections,

a Faulty Charge Relay or ECU.

|

|

Charge Relay Driver Circuit Open

|

520220

|

5

|

P163C

|

This Trouble Code Sets if the Charge Relay Driver Circuit

is Open. Can be caused by Damaged Wiring/Connections, a Charge Relay

or ECU.

|

|

Oil Pump or Fuel Injector Offset not Programmed

|

520241

|

13

|

P1278

|

This Trouble Code Sets if Either the Fuel Injector or Oil

Injection Pump Calibration has Not Been Programmed. Update the Injector/Oil

Pump Settings. WARNING: Do Not Operate the Vehicle with This Trouble

Code Set!

|

|

Ground Speed Pulses Per Mile not Programmed

|

520242

|

13

|

P1279

|

This Trouble Code Sets if the Vehicle Speed Sensor Setting

is Not Properly Programmed in the ECU. Reset the ECU Offset Values

to Resolve this Fault Condition.

|

|

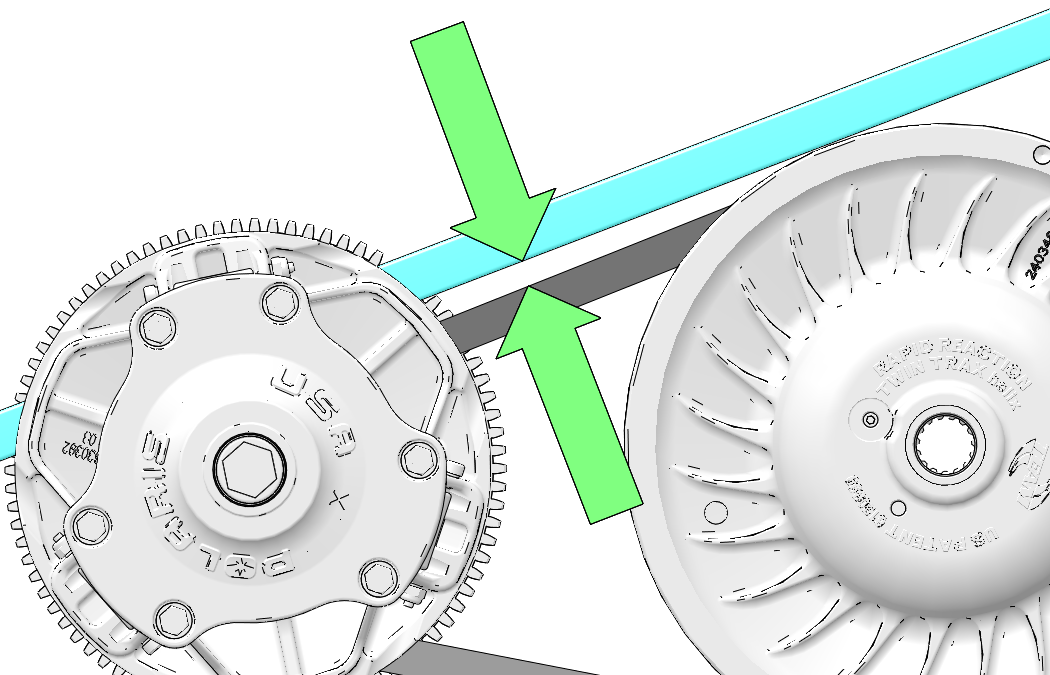

Exhaust Valve Position Out of Range (Open)

|

520325

|

31

|

P140A

|

This Trouble Code sets if: Valve UP position voltage out

of range. Check the following: (1) Measure cable travel length, (2)

Verify smooth valve operation by operating the cable by hand through

its full travel, (3) Relearn EVIf no problem.

|

|

Exhaust Valve Position Out of Range (Mid)

|

520326

|

31

|

P140B

|

This Trouble Code sets if: Valve MID position voltage out

of range. Check the following: (1) Measure cable travel length, (2)

Verify smooth valve operation by operating the cable by hand through

its full travel, (3) Relearn EVIf no problem.

|

|

Exhaust Valve Position Out of Range (Closed)

|

520327

|

31

|

P140C

|

This Trouble Code sets if: Valve DOWN position voltage out

of range. Check the following: If occasional, this fault is nothing

to be concerned about If persistent: Measure cable travel length and

Verify smooth valve operation.

|

|

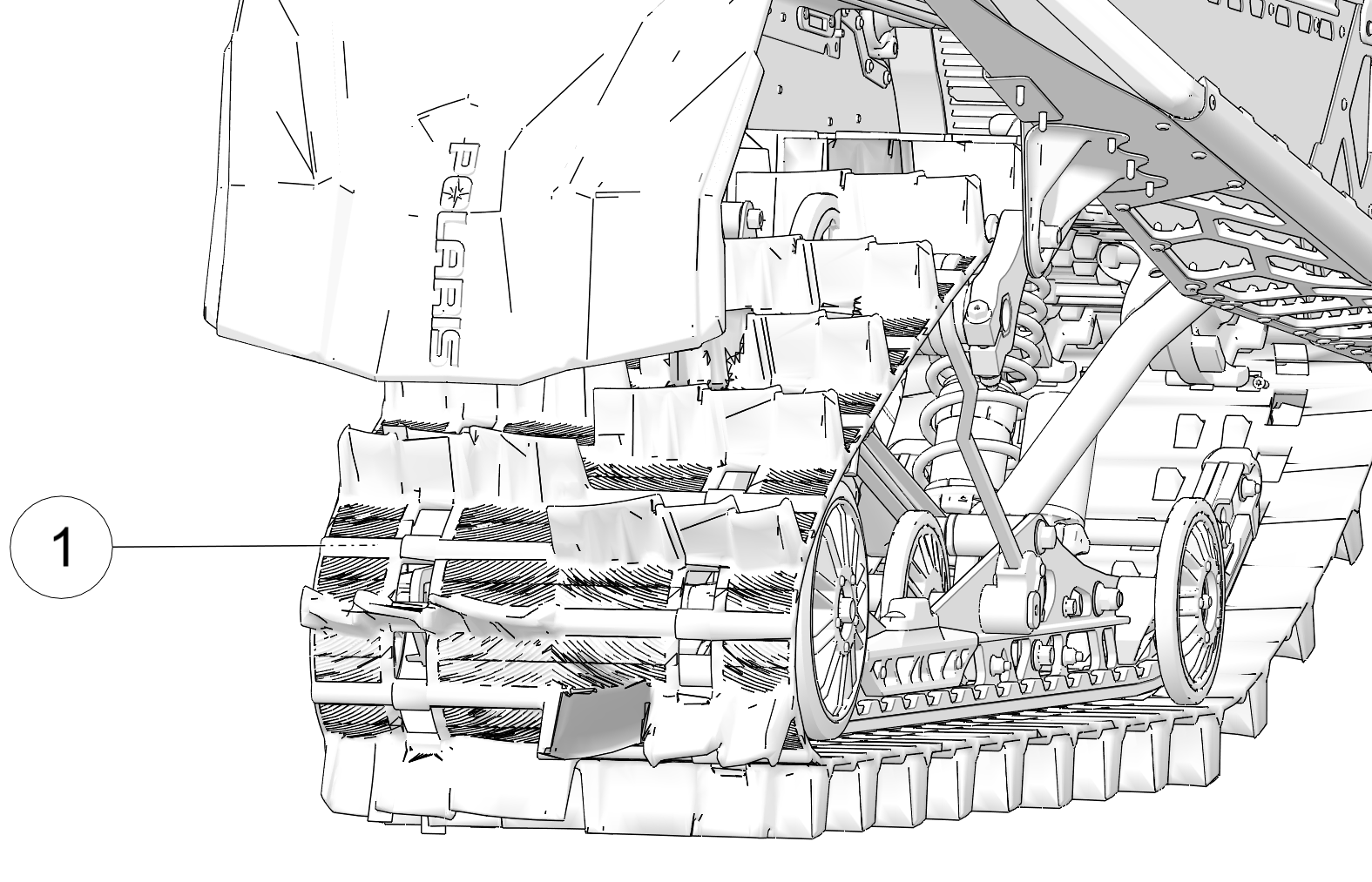

Riding With Brakes On Moderately Severe

|

520555

|

31

|

C2418

|

This Trouble Code Sets if the Sled has been driven with

the brakes applied continuously for 10 seconds, 4500 RPM.

|

|

Riding With Brakes On Most Severe

|

520556

|

31

|

C2419

|

This Trouble Code Sets if the Sled has been driven with

the brakes applied continuously for 20 seconds , 4500 RPM.

|

|

Regulator Near Thermal Shutdown

|

520660

|

31

|

P161B

|

This Trouble Code Sets if the Regulator is near the thermal

shutdown point. Can be caused by excessive power consumption or insufficient

cooling air flow.

|

|

Batch Fire Detection

|

523959

|

31

|

P3022

|

This Trouble Code Sets if the engine is in "Batch Fire Mode".

Can be caused by Damaged Wiring, a faulty Crankshaft Sensor or ECU

/ Connections.

|

|

Exhaust Valve Actuator Short Circuit

|

523958

|

3

|

P3023

|

This trouble code sets if the ECU detects a short in the

EV Actuator Drive circuit. Can be caused by Damaged Wiring, Faulty

EV Actuator, or ECU / Connections. Inspect EV Actuator Drive wires.

(White/Green & White/Blue).

|

|

Exhaust Valve Actuator Open Circuit

|

523958

|

5

|

P3024

|

This trouble code sets if the ECU detects low current or

an open EV Actuator Drive circuit. Can be caused by Damaged Wiring,

Faulty EV Actuator, or ECU / Connections. Inspect EV Actuator Drive

wires. (White/Green & White/Blue).

|

|

Exhaust Valve Actuator Open Circuit

|

523958

|

4

|

P3025

|

This trouble code sets if the ECU detects low current or

an open EV Actuator Drive circuit. Can be caused by Damaged Wiring,

Faulty EV Actuator, or ECU / Connections. Inspect EV Actuator Drive

wires. (White/Green & White/Blue).

|

|

Exhaust Valve Actuator Over Current

|

523958

|

6

|

P3026

|

This trouble code sets if the ECU detects high current on

the EV Actuator Drive circuit. Can be caused by Damaged Wiring, Faulty

EV Actuator, or ECU / Connections. Inspect EV Actuator Drive wires.

(White/Green & White/Blue).

|

|

Exhaust Valve Actuator Internal IC Voltage High

|

523957

|

3

|

P3027

|

This trouble code sets if the ECU has detected a Exhaust

Valve Actuator internal IC voltage above 6V. Can be caused by a faulty

ECU.

|

|

Exhaust Valve Actuator Internal IC Voltage Low

|

523957

|

4

|

P3028

|

This trouble code sets if the ECU has detected a Exhaust

Valve Actuator internal IC voltage Below 4V. Can be caused by a faulty

ECU.

|

|

Exhaust Valve Actuator Internal IC Over Current / Over Temp

|

523957

|

6

|

P3029

|

This trouble code sets if the ECU has detected a Exhaust

Valve Actuator internal IC current above 2A or 200C. Can be caused

by a faulty ECU.

|

|

Exhaust Valve Actuator Internal IC Communication Loss

|

523957

|

19

|

P3032

|

This trouble code sets if the ECU loses communication with

the Exhaust Valve Actuator IC. Can be cause by a faulty ECU.

|

|

Exhaust Valve Actuator Position Sensor Voltage High

|

523956

|

3

|

P3033

|

This trouble code sets if the Exhaust Valve Actuator Position

Sensor voltage is greater than 4.5V for 1 sec. Can be caused by Damaged

wiring, Faulty EV actuator, or ECU / Connections. Inspect EV Actuator

Position Sensor wires. Power: Red/White. Ground: Brown/White. Feedback:

Dark Green/Orange.

|

|

Exhaust Valve Actuator Position Sensor Voltage Low

|

523956

|

4

|

P3034

|

This trouble code sets if the Exhaust Valve Actuator Position

Sensor voltage is Less than 0.4V for 1 sec. Can be caused by Damaged

wiring, Faulty EV actuator, or ECU / Connections. Inspect EV Actuator

Position Sensor wires. Power: Red/White. Ground: Brown/White. Feedback:

Dark Green/Orange.

|

|

Exhaust Valve Actuator Abnomral Rate of Change

|

523956

|

10

|

P3035

|

This trouble code sets if the Exhaust Valve Actuator Position

Sensor voltage is Less than 0.4V for 1 sec. Can be caused by Damaged

wiring, Faulty EV actuator, or ECU / Connections. Inspect EV Actuator

Position Sensor wires. Power: Red/White. Ground: Brown/White. Feedback:

Dark Green/Orange.

|

|

Exhaust Valve Learning Default Position

|

520337

|

7

|

P3036

|

This trouble code sets if the Exhaust Valve Learn values

are different from the Exhaust Valve Check Values. Can be caused by

an obstruction in the Exhaust Valves, Broken Cable, or broken Exhaust

Valve.

|

|

Water Temperature Unrealistic Transition

|

110

|

10

|

P0119

|

This trouble code sets if the water temperature changes

by 20C in 1 sec 3 times. Can be caused by Faulty Wiring, Faulty Water

Temperature Sensor, or Faulty ECU.

|

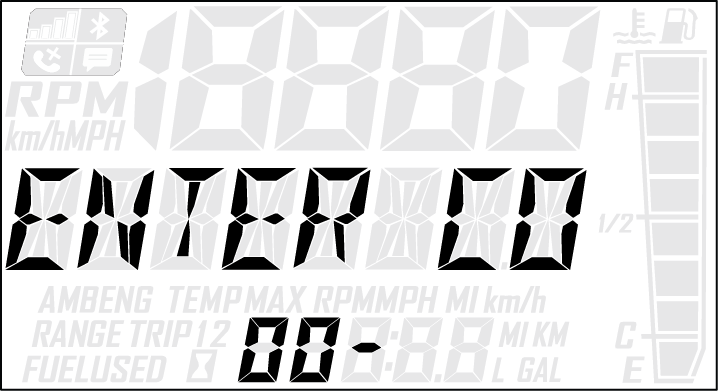

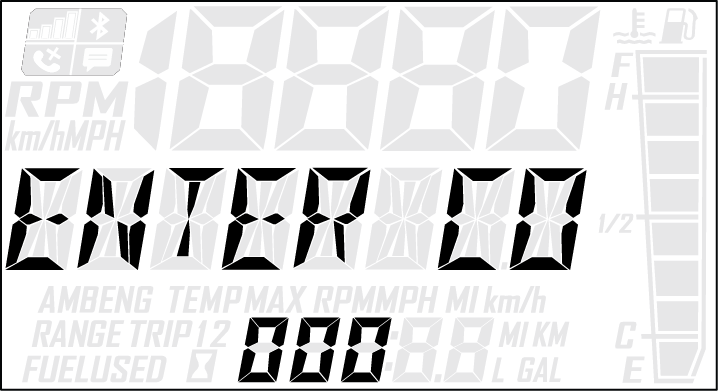

button on the instrument cluster to enter the Options Menu.

button on the instrument cluster to enter the Options Menu.