This Emissions Limited Warranty is in addition to the POLARIS standard

Limited Warranty for your vehicle. POLARIS Industries Inc. warrants

that at the time it is first purchased, this emissions-certified vehicle

is designed, built and equipped so it conforms with applicable U.S.

Environmental Protection Agency emission regulations. POLARIS warrants

that the vehicle is free from defects in materials and workmanship

that would cause it to fail to meet these regulations.

The warranty period for this emissions-certified vehicle starts

on the date the vehicle is first purchased and continues for a period

of 200 hours of engine operation; 4,000 kilometers (2,485 miles) of

vehicle travel; or 30 calendar months from the date of purchase, whichever

comes first.

This Emissions Limited Warranty covers components if their failure

increases the vehicle’s regulated emissions, and it covers

components of systems if their only purpose is to control emissions.

Repairing or replacing other components not covered by this warranty

is the responsibility of the vehicle owner. This Emissions Limited

Warranty does not cover components if their failure does not increase

the vehicle’s regulated emissions.

For exhaust emissions, emission-related components include any

engine parts related to the following systems:

-

Air-induction system

-

Fuel system

The following parts are also considered emission-related components

for exhaust emissions:

-

Sensors

-

Electronic control units

The following parts are considered emission-related components

for evaporative emissions:

-

Fuel Tank

-

Fuel Cap

-

Fuel Line

-

Fuel Line Fittings

-

Clamps*

-

Pressure Relief Valves*

-

Control Valves*

-

Control Solenoids*

-

Electronic Controls*

-

Vacuum Control Diaphragms*

-

Control Cables*

-

Control Linkages*

-

Purge Valves

-

Vapor Hoses

-

Liquid/Vapor Separator

-

Carbon Canister

-

Canister Mounting Brackets

-

Carburetor Purge Port Connector

*As related to the evaporative emission control system.

The exclusive remedy for breach of this Limited Warranty shall

be, at the exclusive option of POLARIS, repair or replacement of any

defective materials, components or products. THE REMEDIES SET FORTH

IN THIS LIMITED WARRANTY ARE THE ONLY REMEDIES AVAILABLE TO ANY PERSON

FOR BREACH OF THIS WARRANTY. POLARIS SHALL HAVE NO LIABILITY TO ANY

PERSON FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY DESCRIPTION,WHETHER

ARISING OUT OF EXPRESS OR IMPLIED WARRANTY OR ANY OTHER CONTRACT,

NEGLIGENCE OR OTHER TORT OR OTHERWISE. THIS EXCLUSION OF CONSEQUENTIAL,

INCIDENTAL, AND SPECIAL DAMAGES IS INDEPENDENT FROM AND SHALL SURVIVE

ANY FINDING THAT THE EXCLUSIVE REMEDY FAILED OF ITS ESSENTIAL PURPOSE.

ALL IMPLIED WARRANTIES (INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE)

ARE LIMITED IN DURATION TO THE WARRANTY PERIOD DESCRIBED HEREIN. POLARIS

DISCLAIMS ALL EXPRESS WARRANTIES NOT STATED IN THIS WARRANTY. Some

states do not allow limitations on how long an implied warranty lasts,

so the above limitation may not apply if it is inconsistent with the

controlling state law.

This Limited Warranty excludes failures not caused by a defect

in material or workmanship. This Limited Warranty does not cover damage

due to accidents, abuse or improper handling, maintenance or use.

This Limited Warranty also does not cover damage to any engine as

a result of being structurally altered, or when the vehicle has been

used in racing competition. This Limited Warranty also does not cover

physical damage, corrosion or defects caused by fire, explosions or

other similar causes beyond the control of POLARIS.

Owners are responsible for performing the scheduled maintenance

identified in the owner’s manual. POLARIS may deny warranty

claims for failures that have been caused by the owner’s or

operator’s improper maintenance or use, by accidents for which

POLARIS has no responsibility, or by acts of God.

Any qualified repair shop or person may maintain, replace, or repair

the emission control devices or systems on your vehicle. POLARIS recommends

that you contact an authorized POLARIS dealer to perform any service

that may be necessary for your vehicle. POLARIS also recommends that

you use only POLARIS parts, however, equivalent parts may be used

for such service. It is a potential violation of the Clean Air Act

if a part supplied by an aftermarket parts manufacturer reduces the

effectiveness of the vehicle’s emission controls. Tampering

with emission controls is prohibited by federal law.

If you have any questions regarding your warranty rights and responsibilities,

please contact POLARIS Owner Connections:

United States & Canada: 1-800-POLARIS (1-800-765-2747) or visit

polaris.com.

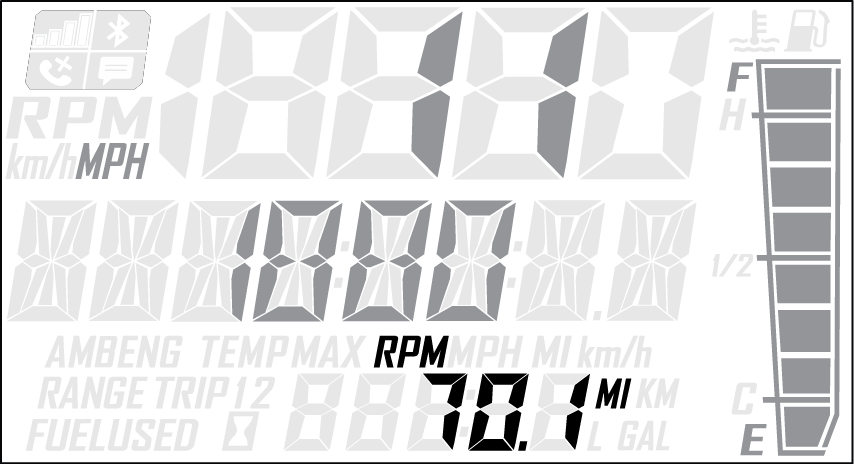

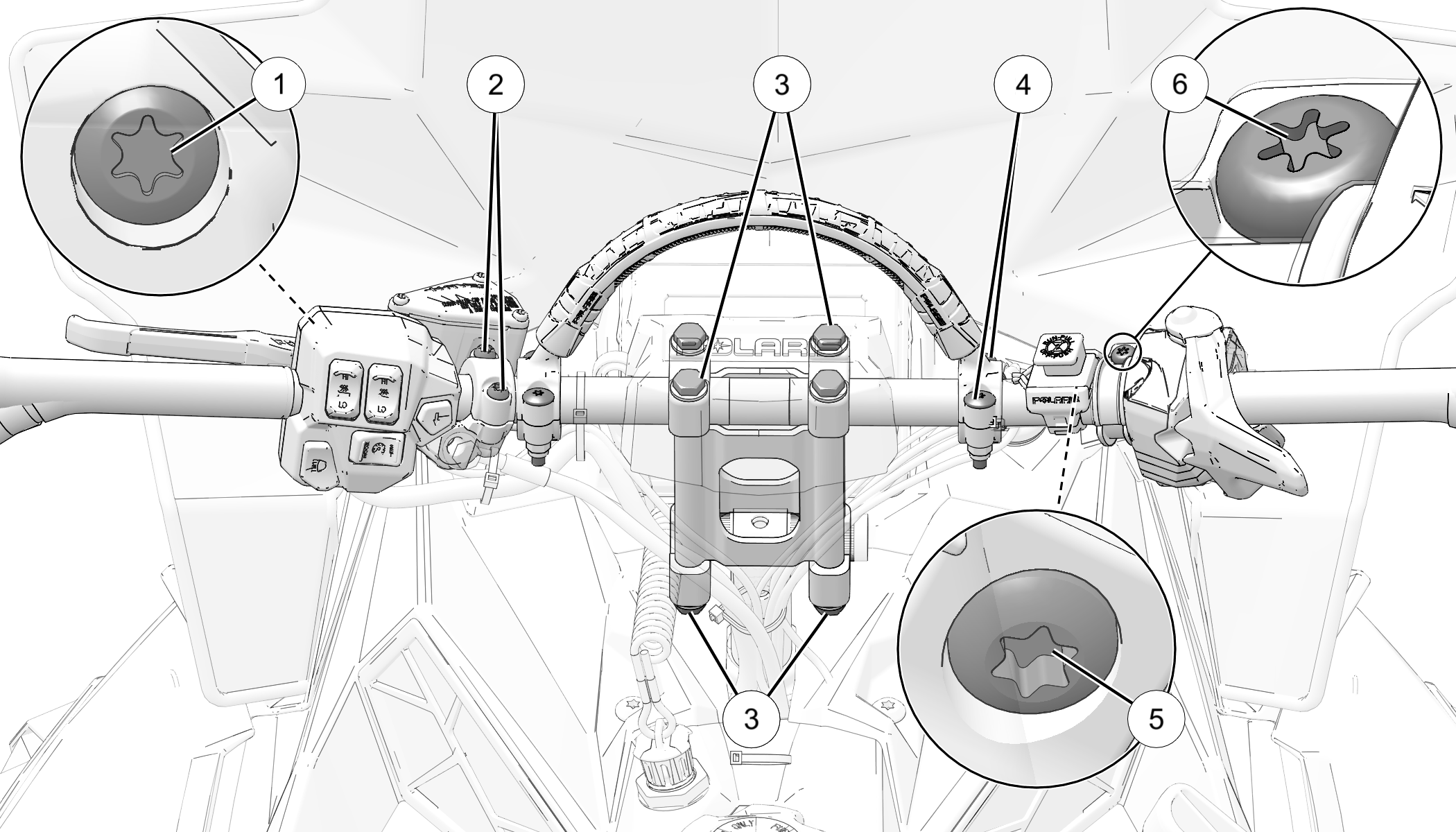

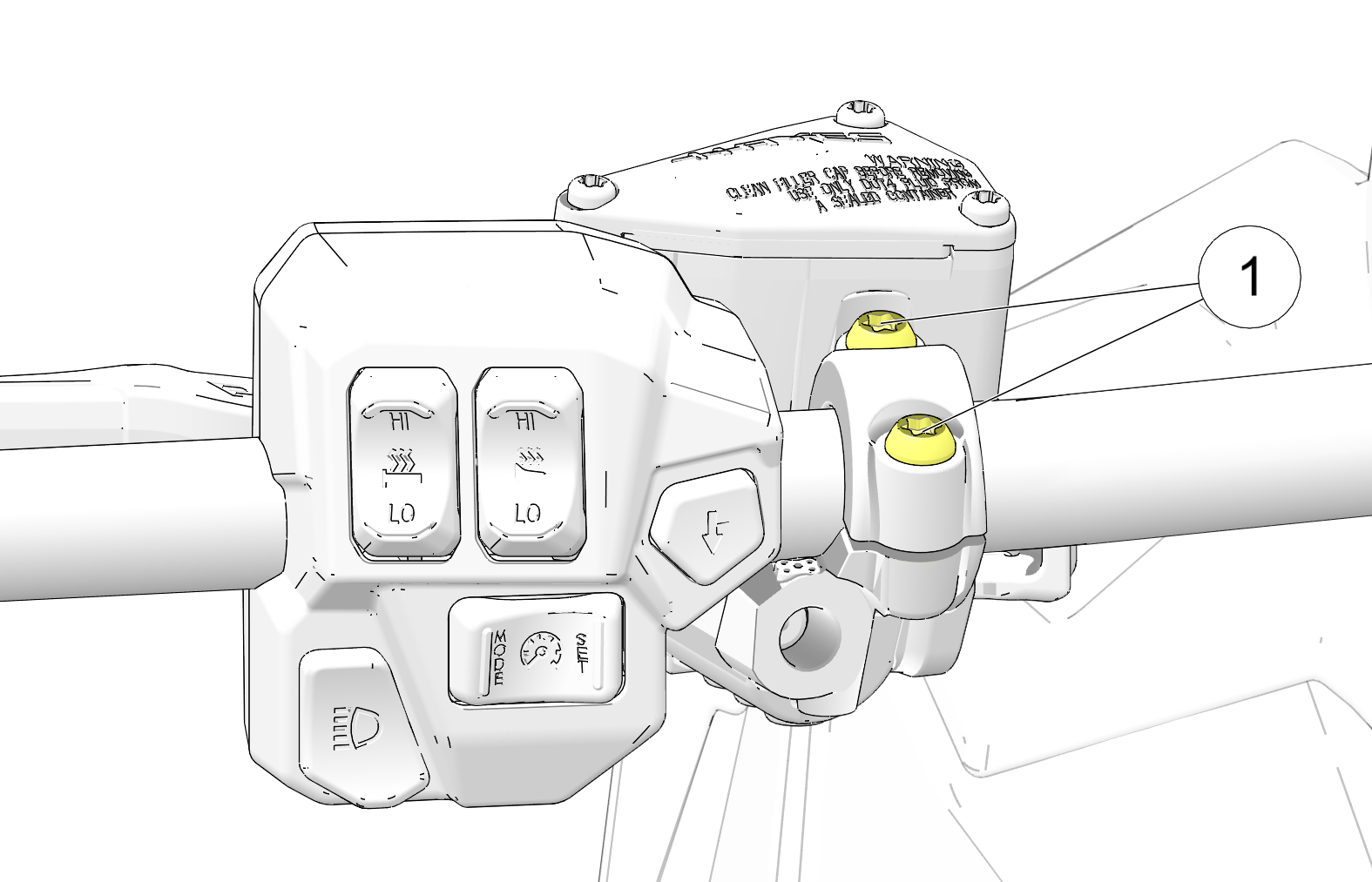

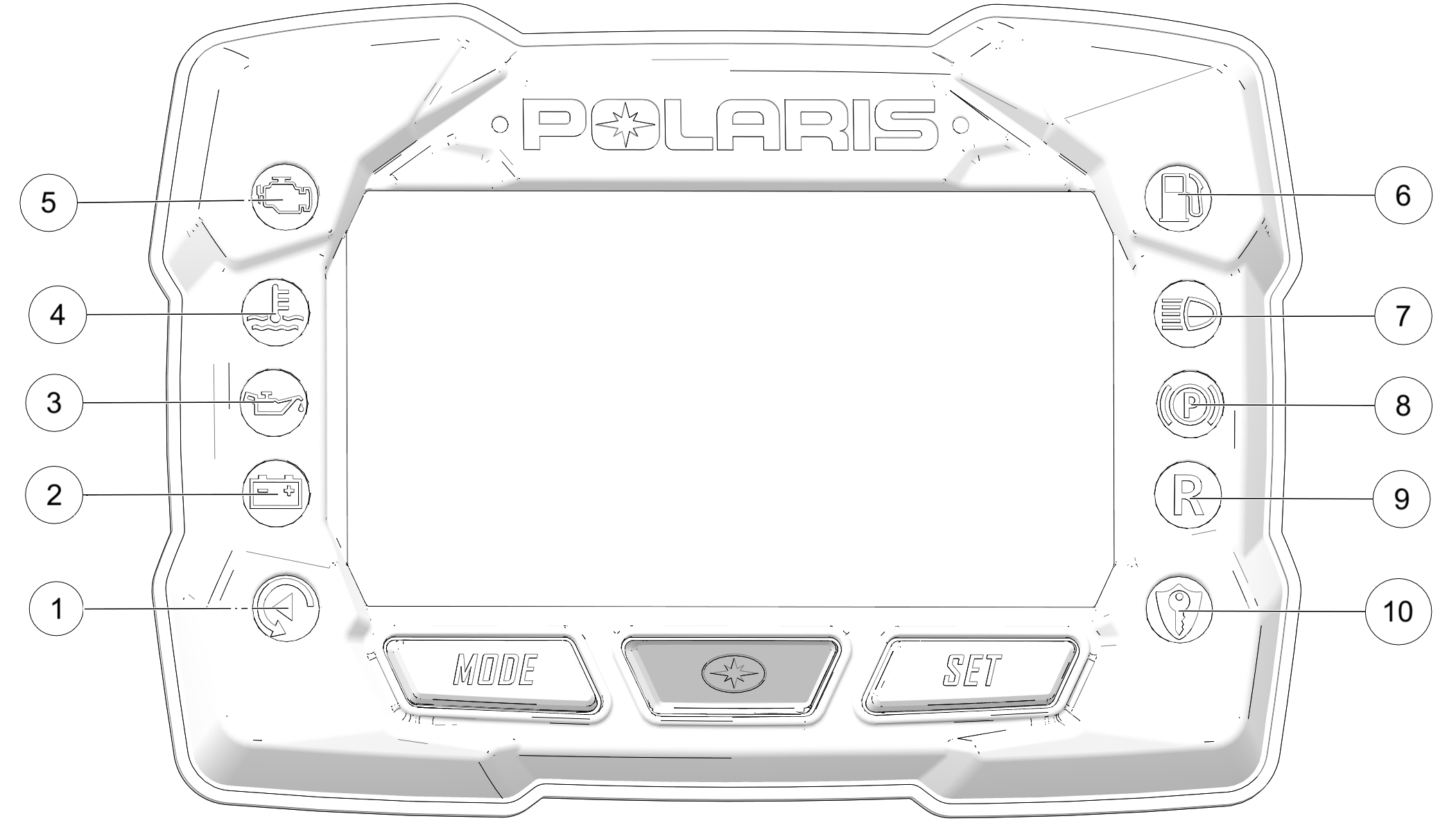

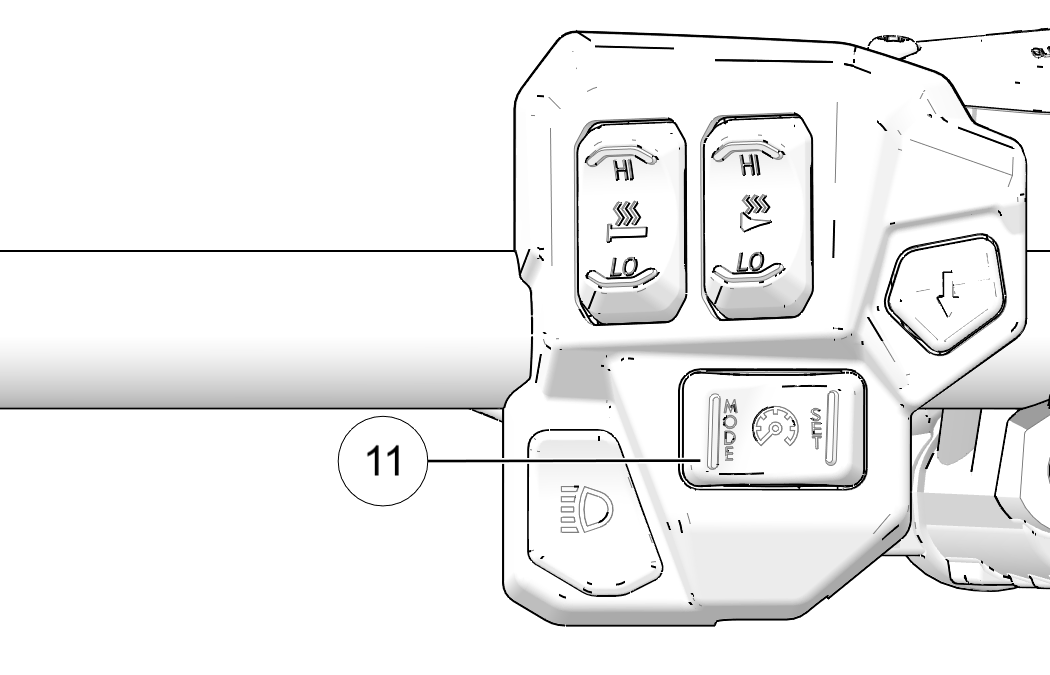

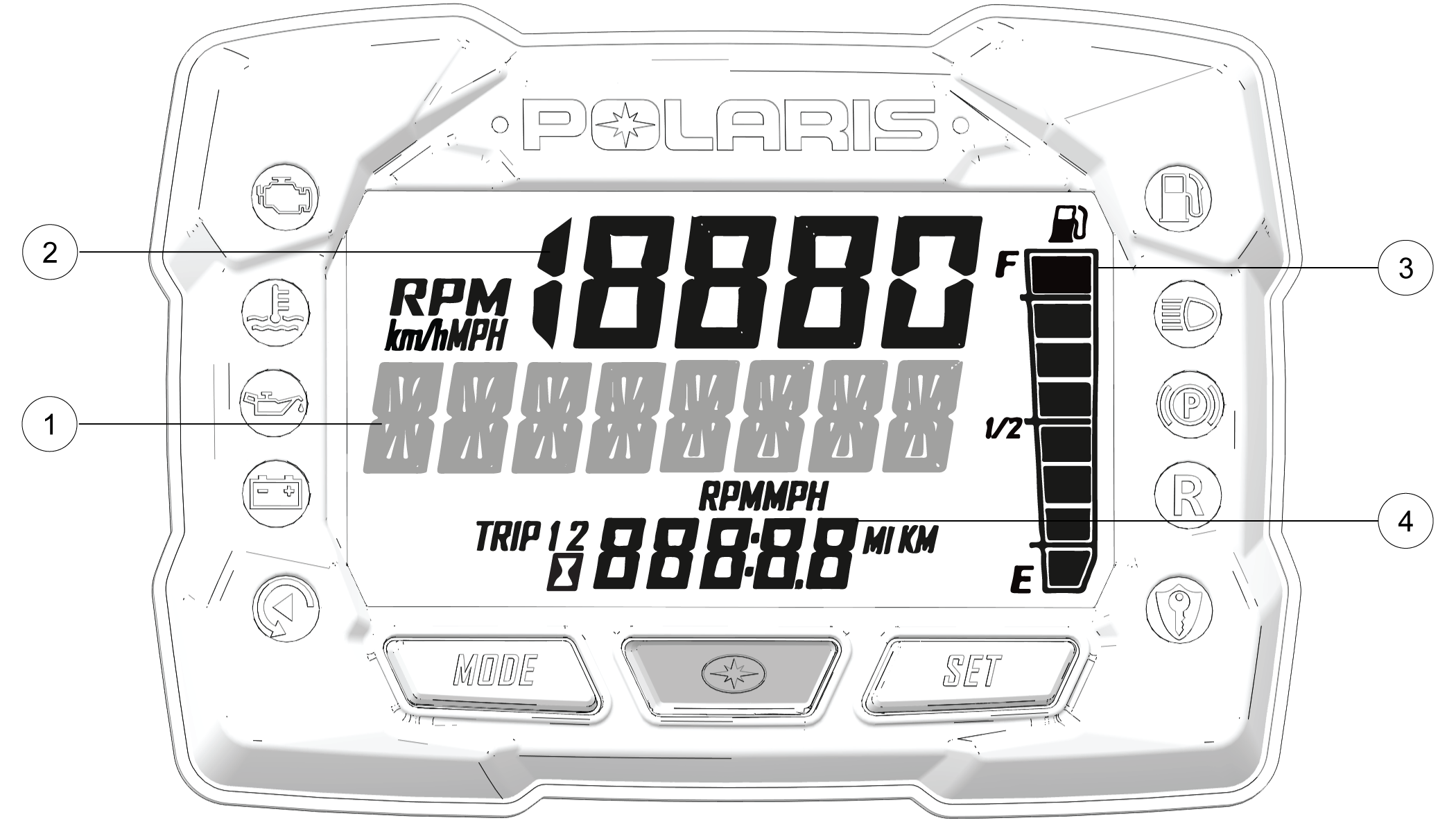

button on the instrument cluster to enter the Options Menu.

button on the instrument cluster to enter the Options Menu.