Drive Belt Tension Check

-

Inspect drive belt for damage and wear.

-

Ensure rear wheel is elevated before checking tension or adjusting.

-

Use tire valve stem as a reference and perform following steps:

-

Check/record belt deflection at 4 different points, 90° apart. Rotate wheel in a COUNTER-CLOCKWISE rotation as viewed from belt side of motorcycle.

-

Place a mark on rear wheel at tightest point (least deflection) to use as a reference.

-

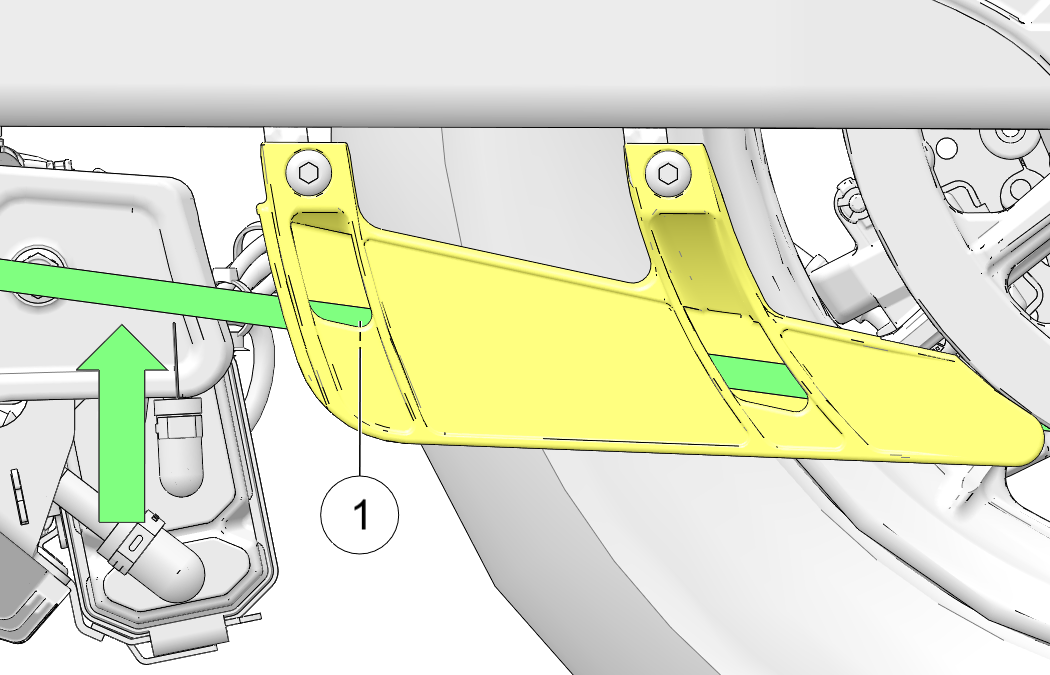

Continue to rotate wheel in normal drive direction (COUNTER-CLOCKWISE) 1–2 revolutions until your reference mark (tightest point) is lined up with tension setting window in lower belt guard 1.

-

Adjust belt deflection with wheel in this position.

-

-

Place tape measure or ruler next to drive belt.

-

Slide O-ring on belt tension gauge (Special tool PV-43532) to 10 lb (4.54 kg) mark.

-

Place belt tension gauge squarely against belt at center and keep it at a 90° angle to the belt surface.

-

Push up on gauge until O-ring just touches tool body and compare to specification.

MEASUREMENTDrive Belt Deflection @ 10 lbs force:

15/32 in (12 mm)

-

If belt deflects more than specified distance with 10 lb (4.54 kg) of force, proceed to Drive Belt Adjustment section and tighten belt. If belt deflection is less than specified, proceed to Drive Belt Adjustment section and loosen belt. If belt deflection is correct, lower motorcycle.