Spark Plug Maintenance

Inspect / replace the spark plugs as outlined in the periodic maintenance table.

The spark plugs can be serviced by using the following procedure.

-

Remove the side panels and hood.

-

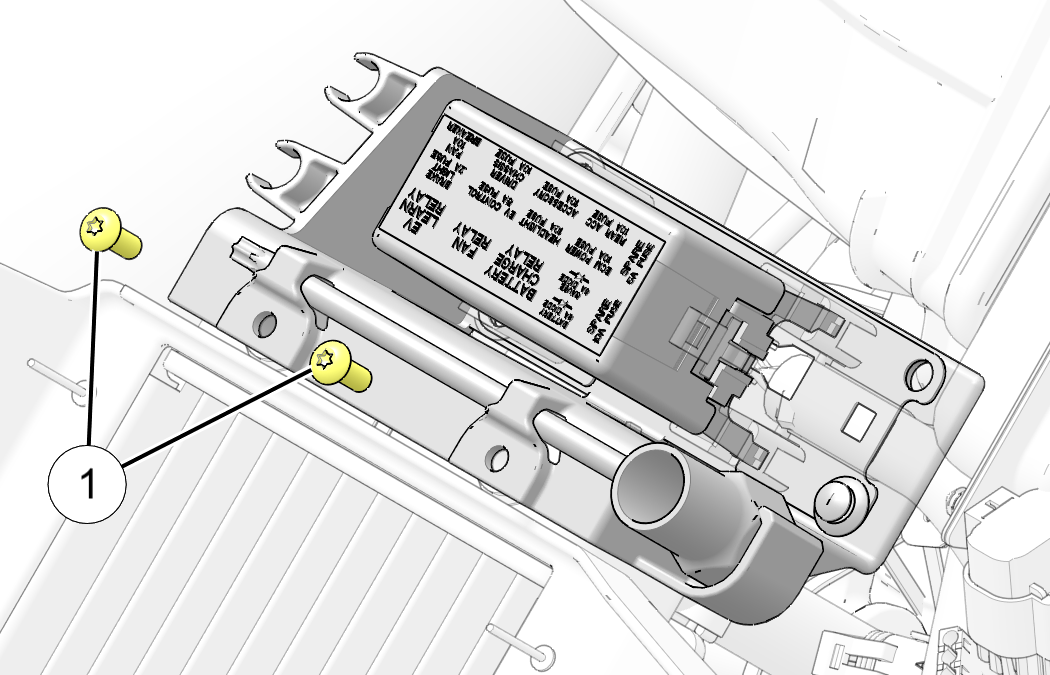

Using the torx tool end of the spark plug wrench, remove bolts retaining the load center 1.

-

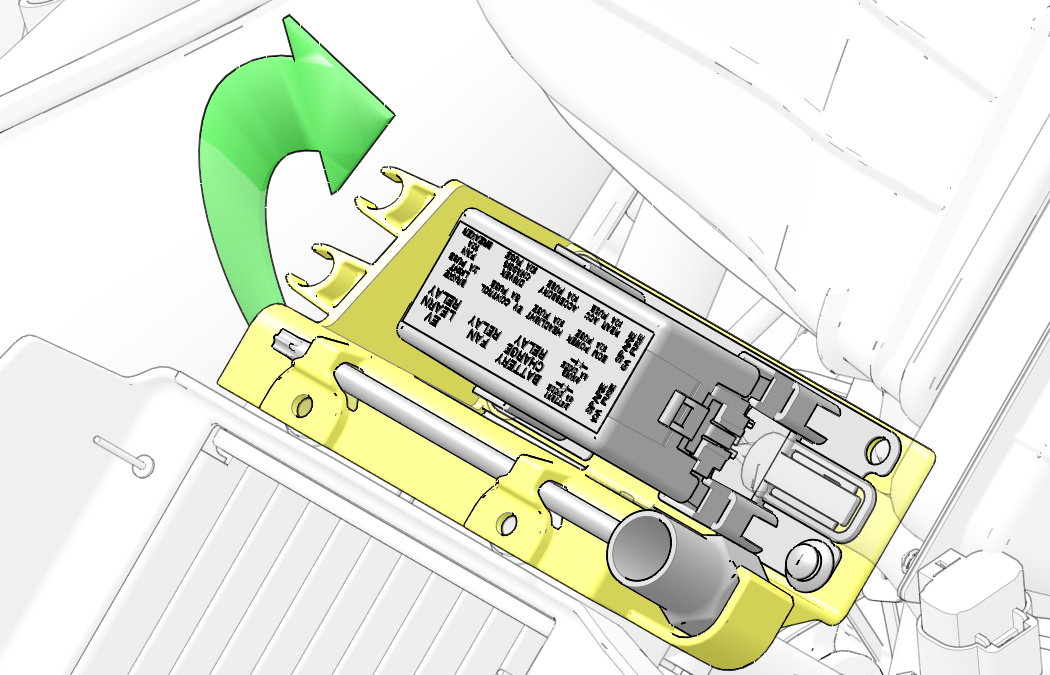

Carefully rotate load center away from radiator.

-

Remove the spark plug leads.

-

Clean the plug area so no debris can fall into engine when plug is removed.

-

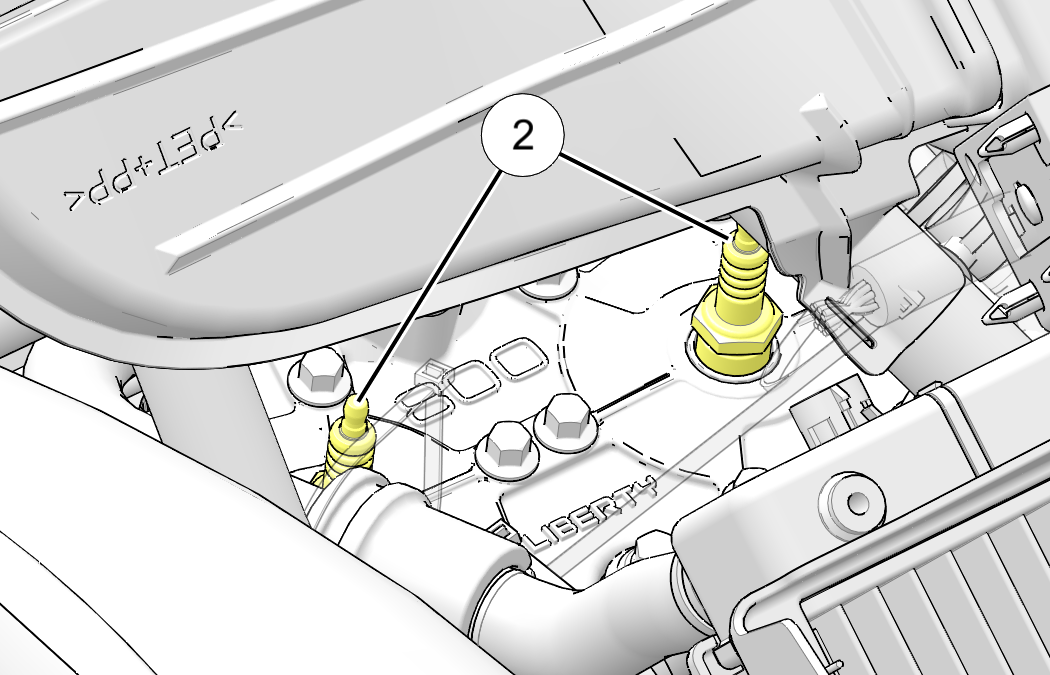

Using the spark plug wrench provided in the tool kit, remove plug(s) 2 by rotating it counter clockwise.

Replace spark plug if the following is observed:

-

Electrode damage / insulator cracked

-

Electrode / insulator is fouled

-

Regular replacement interval found on maintenance table

When inspecting a spark plug, take note of the electrode and insulator color. A light brown/dark tan color indicates the engine is running properly. If the spark plug electrode/insulator is white, the engine may be running lean. Inspect the engine, throttle body boots, etc. for air leaks.

If the spark plug electrode/insulator is black, oily, or shows heavy soot, the engine may be running rich. Inspect the engine, fuel system, and lubrication system for problems.

Set the electrode gap to specification before installing a new spark plug.

NGK® BPR9ES Gap:

.027″ (0.70 mm)

When installing spark plug(s), install clean and dry. Torque to specification.

Spark Plug Torque:

18 - 22 ft-lbs (24 - 30 Nm)