Drive Belt Adjustment

Perform this procedure to achieve proper belt tension and alignment. Belt tension should be set before performing the alignment procedure.

Belt Tension

A drive belt that is not properly tensioned can cause drive line noise and damage the drive belt, causing possible belt failure and loss of control of the motorcycle.

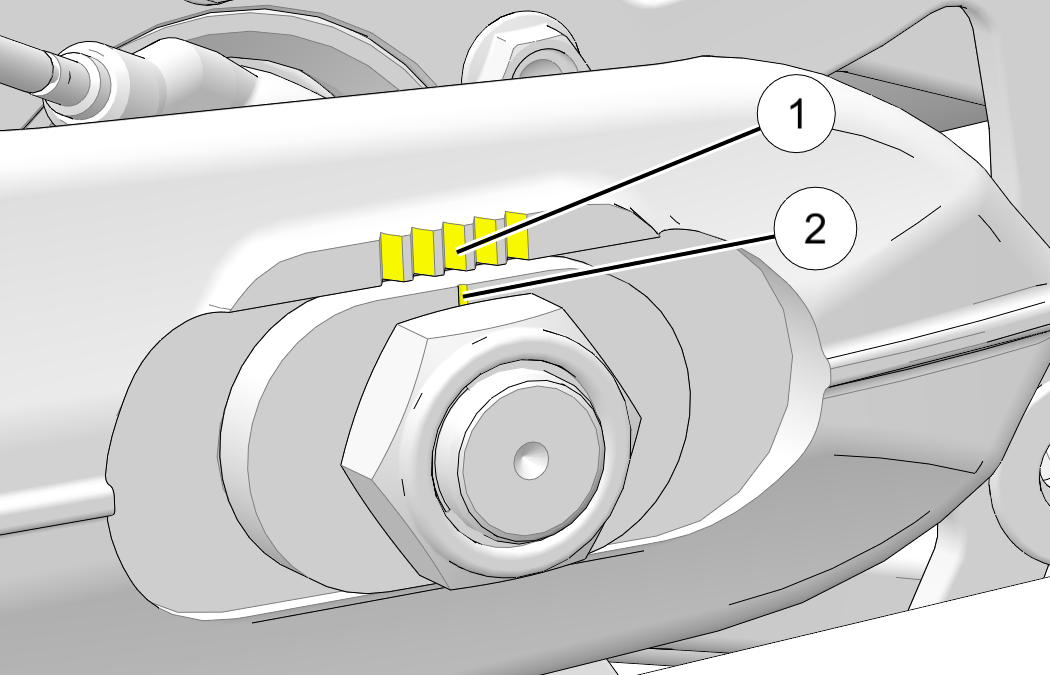

Marks 1 and 2 are used as a reference for initial wheel alignment. Marks should be in roughly the same position on both left and right sides of wheel.

-

Place the motorcycle in an upright position with the front wheel clamped in a wheel vise.

-

Remove saddlebags.

-

Make note of adjuster locations 1 and 2.

-

Raise the rear of the motorcycle so the rear tire can be freely rotated.

-

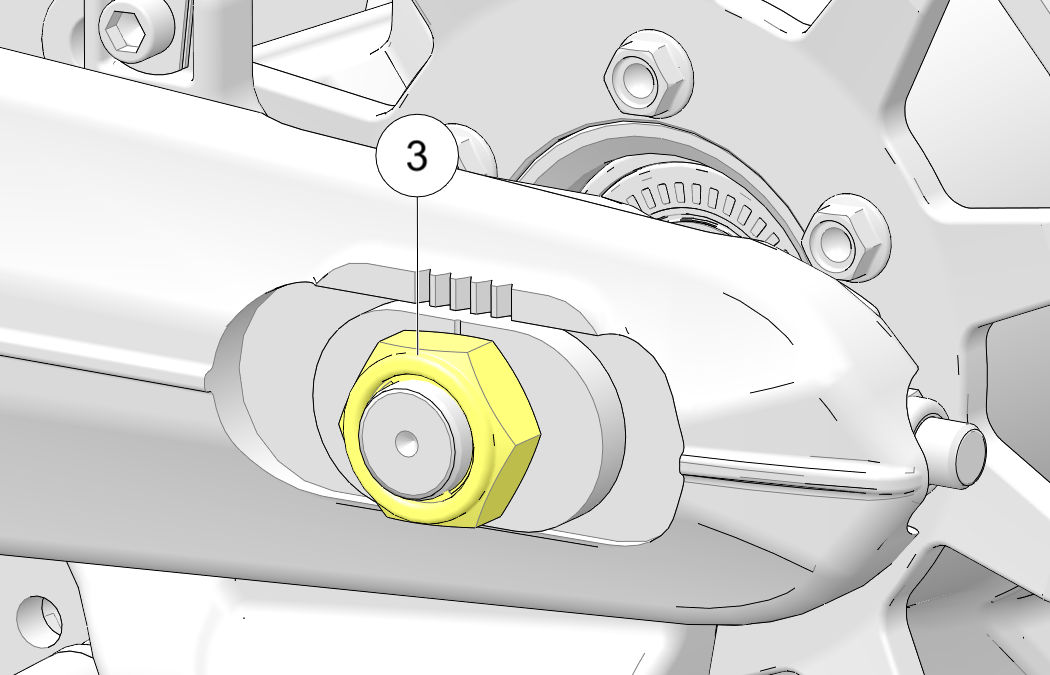

Loosen axle nut 3.

-

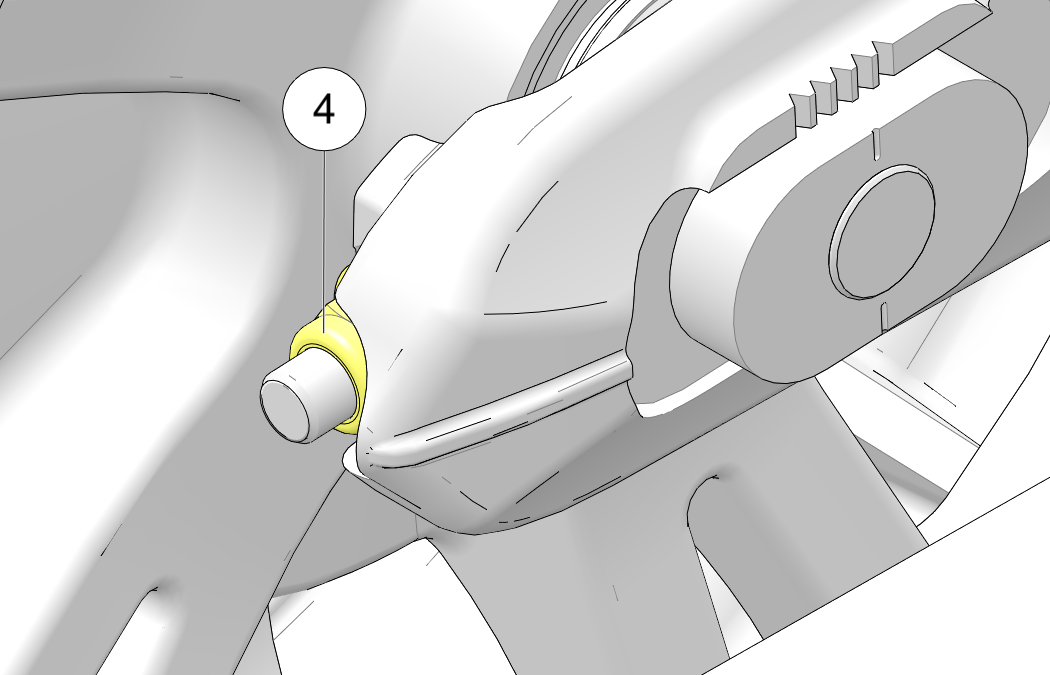

Turn the RIGHT SIDE adjuster nut 4 to achieve proper belt tension

| Belt Deflection | |

|---|---|

| Model | Deflection @ 10 lbs force |

|

Challenger |

0.6 in (15 mm) - New Belt 0.79 in (20 mm) - Belt with 1000+ miles |

Belt Alignment

A drive belt that is not properly aligned can cause drive line noise and damage the drive belt, causing possible belt failure and loss of control of the motorcycle.

Once the belt tension is correct, check and adjust final wheel alignment as follows:

To minimize change in belt tension, use LEFT SIDE adjuster only to make final adjustments to belt alignment.

-

Rotate the wheel BACKWARD. Tighten LEFT SIDE adjuster until belt comes off inside sprocket flange during backward wheel rotation.

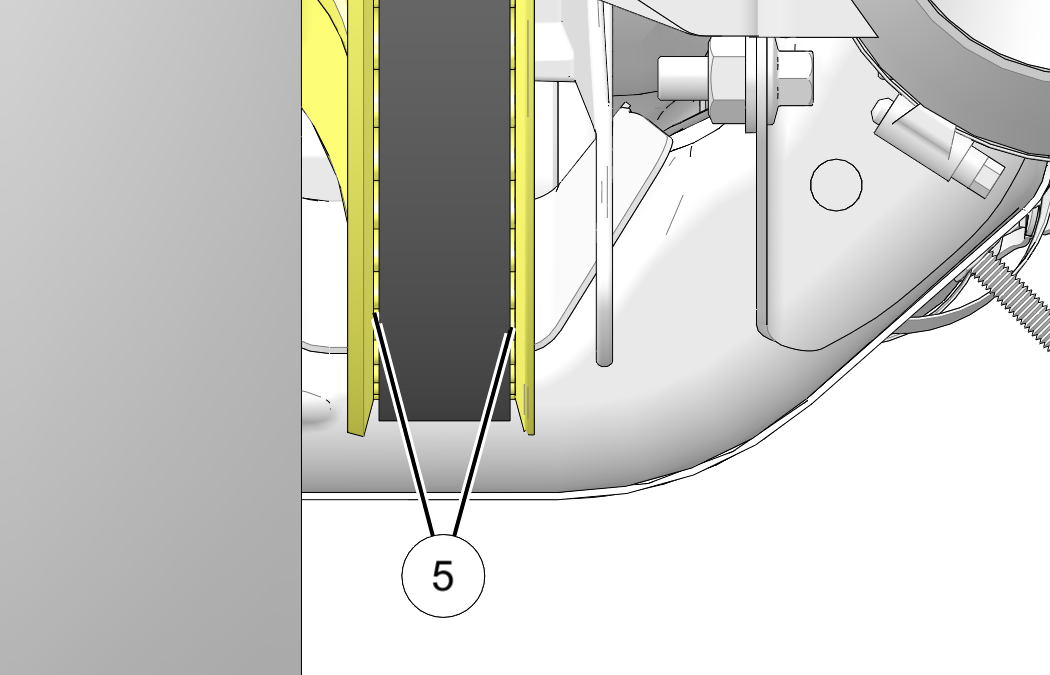

IMPORTANTThe belt should track to the center of the sprocket tooth surface when properly aligned 5. Sprocket teeth should be visible on both sides of the drive belt.

-

Rotate the wheel in the FORWARD direction and verify that sprocket teeth are still visible on both sides of the drive belt 5.

-

If necessary, loosen the axle nut and LEFT SIDE adjuster until belt just moves off the right flange and begins to track down the center of the driven sprocket flange during forward wheel rotation.

NOTICEIt may be necessary to loosen the axle nut and tap the left end of the axle to ensure it moves forward when the adjuster is loosened. The axle nut must be retightened to the ADJUSTMENT SPECIFICATION before proceeding.

-

Rear wheel alignment is satisfactory when the drive belt remains centered on driven sprocket during forward and backward wheel rotation. Sprocket teeth should be visible from both sides of the drive belt.

-

Verify that drive belt tension is still within specification.

-

Tighten rear axle nut to specification.

TORQUEAxle Nut Torque:

65 ft-lbs (88 N·m)

-

Pump rear brake pedal several times to reset brake pad distance.

-

Verify wheel rotates smoothly and freely without drag when brake pedal is released.